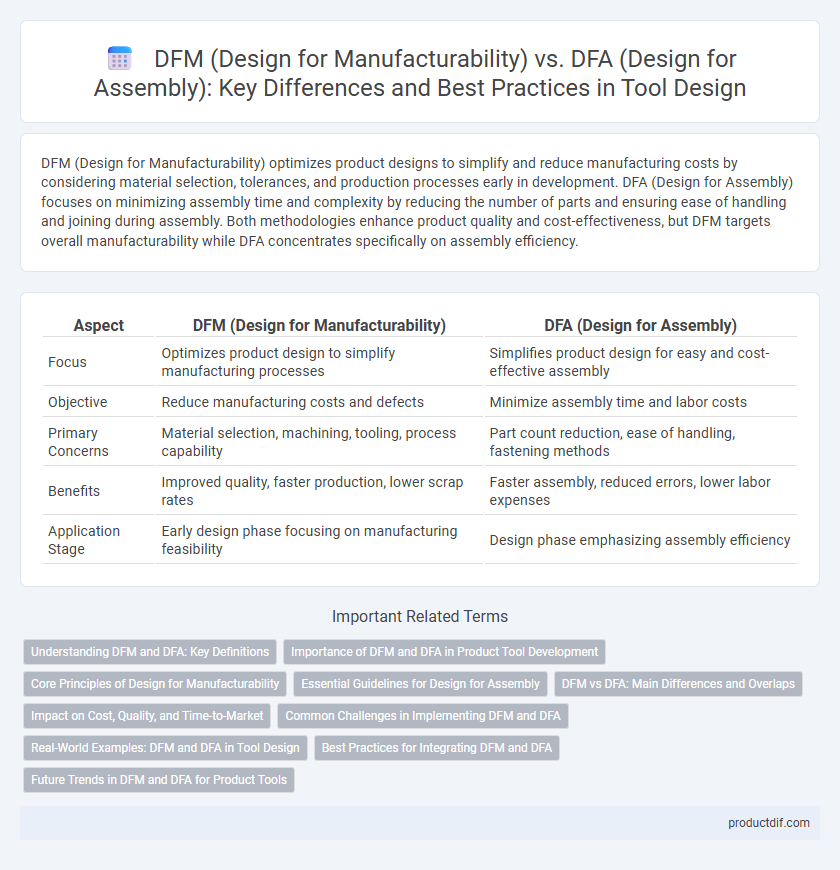

DFM (Design for Manufacturability) optimizes product designs to simplify and reduce manufacturing costs by considering material selection, tolerances, and production processes early in development. DFA (Design for Assembly) focuses on minimizing assembly time and complexity by reducing the number of parts and ensuring ease of handling and joining during assembly. Both methodologies enhance product quality and cost-effectiveness, but DFM targets overall manufacturability while DFA concentrates specifically on assembly efficiency.

Table of Comparison

| Aspect | DFM (Design for Manufacturability) | DFA (Design for Assembly) |

|---|---|---|

| Focus | Optimizes product design to simplify manufacturing processes | Simplifies product design for easy and cost-effective assembly |

| Objective | Reduce manufacturing costs and defects | Minimize assembly time and labor costs |

| Primary Concerns | Material selection, machining, tooling, process capability | Part count reduction, ease of handling, fastening methods |

| Benefits | Improved quality, faster production, lower scrap rates | Faster assembly, reduced errors, lower labor expenses |

| Application Stage | Early design phase focusing on manufacturing feasibility | Design phase emphasizing assembly efficiency |

Understanding DFM and DFA: Key Definitions

DFM (Design for Manufacturability) focuses on simplifying the manufacturing process to reduce production costs and improve quality by considering material selection, machining processes, and tolerances during the design phase. DFA (Design for Assembly) emphasizes minimizing the complexity and number of parts to streamline product assembly, thereby reducing labor time and assembly costs. Both DFM and DFA are integral to optimizing product design for efficient manufacturing and assembly workflows, enhancing overall production efficiency and product reliability.

Importance of DFM and DFA in Product Tool Development

DFM (Design for Manufacturability) and DFA (Design for Assembly) are crucial in product tool development to enhance production efficiency and reduce costs. DFM focuses on optimizing the design to simplify manufacturing processes, minimizing material usage and production complexity. DFA ensures ease of assembly by designing parts that fit together seamlessly, reducing assembly time and improving overall product quality.

Core Principles of Design for Manufacturability

Design for Manufacturability (DFM) emphasizes optimizing product design to simplify manufacturing processes, reduce production costs, and improve quality by considering material selection, tolerances, and process capabilities early in the design phase. Core principles of DFM include minimizing part count, standardizing components, and designing for easy fabrication methods such as machining, molding, or casting. In contrast, Design for Assembly (DFA) concentrates on simplifying product assembly by reducing the number of assembly steps, using self-locating and self-fastening features, and ensuring ease of handling and orientation during assembly.

Essential Guidelines for Design for Assembly

Design for Assembly (DFA) emphasizes minimizing part count and simplifying assembly operations to reduce cost and improve reliability. Essential guidelines include using modular components, standardizing parts, and designing for easy handling and orientation during assembly. Prioritizing these strategies enhances production efficiency and supports seamless integration with Design for Manufacturability (DFM) principles.

DFM vs DFA: Main Differences and Overlaps

DFM (Design for Manufacturability) emphasizes optimizing product design to simplify and reduce manufacturing costs, focusing on materials selection, machining processes, and production efficiency. DFA (Design for Assembly) targets minimizing assembly time and complexity by reducing part count and simplifying component interfaces, improving ease of product assembly. Both methodologies overlap in their aim to enhance product cost-effectiveness and quality, but DFM focuses more on production feasibility while DFA prioritizes streamlined assembly operations.

Impact on Cost, Quality, and Time-to-Market

DFM (Design for Manufacturability) directly reduces production costs and improves product quality by optimizing designs for efficient manufacturing processes. DFA (Design for Assembly) decreases assembly time and labor expenses, enhancing time-to-market and lowering overall costs. Both methodologies collaboratively elevate product reliability and streamline workflows, significantly impacting cost efficiency, quality, and market readiness.

Common Challenges in Implementing DFM and DFA

Common challenges in implementing DFM and DFA include balancing cost reduction with product functionality and quality, as both require different focus areas--DFM targets manufacturability by minimizing complexity and material use, while DFA prioritizes assembly efficiency and ease. Integrating these methodologies often faces obstacles such as conflicting design requirements, limited cross-disciplinary collaboration, and inadequate early-stage involvement of manufacturing and assembly experts. Overcoming these challenges demands a holistic design approach, advanced simulation tools, and iterative feedback loops between design, manufacturing, and assembly teams to optimize the entire production process.

Real-World Examples: DFM and DFA in Tool Design

DFM (Design for Manufacturability) in tool design emphasizes optimizing features to reduce production complexity and costs, such as simplifying component geometries to enable efficient CNC machining processes. DFA (Design for Assembly) focuses on minimizing assembly time and errors by standardizing fasteners and incorporating snap-fit joints, exemplified by modular tool handles designed for easy part interchangeability. Companies like Bosch and Stanley implement DFM by refining part shapes for consistent molding while applying DFA principles to streamline tool assembly lines, improving overall product reliability and manufacturing throughput.

Best Practices for Integrating DFM and DFA

Integrating DFM and DFA best practices enhances product quality and reduces manufacturing costs by optimizing both manufacturability and assembly processes early in design. Emphasizing part simplification, standardization, and modular design improves assembly efficiency while minimizing production complexities and defects. Collaborative cross-functional teams leverage CAD simulations and prototyping to identify and resolve design issues, ensuring seamless manufacturability and assembly integration.

Future Trends in DFM and DFA for Product Tools

Future trends in DFM (Design for Manufacturability) and DFA (Design for Assembly) emphasize increased integration of AI-driven simulation technologies to optimize tool design processes, reducing manufacturing complexity and assembly time. Advanced materials and additive manufacturing techniques enable more precise, lightweight, and customizable tools, enhancing both manufacturability and ease of assembly. Embracing digital twins and IoT connectivity, product tools are evolving toward smarter, data-driven design strategies that improve efficiency and quality in production workflows.

DFM (Design for Manufacturability) vs DFA (Design for Assembly) Infographic

productdif.com

productdif.com