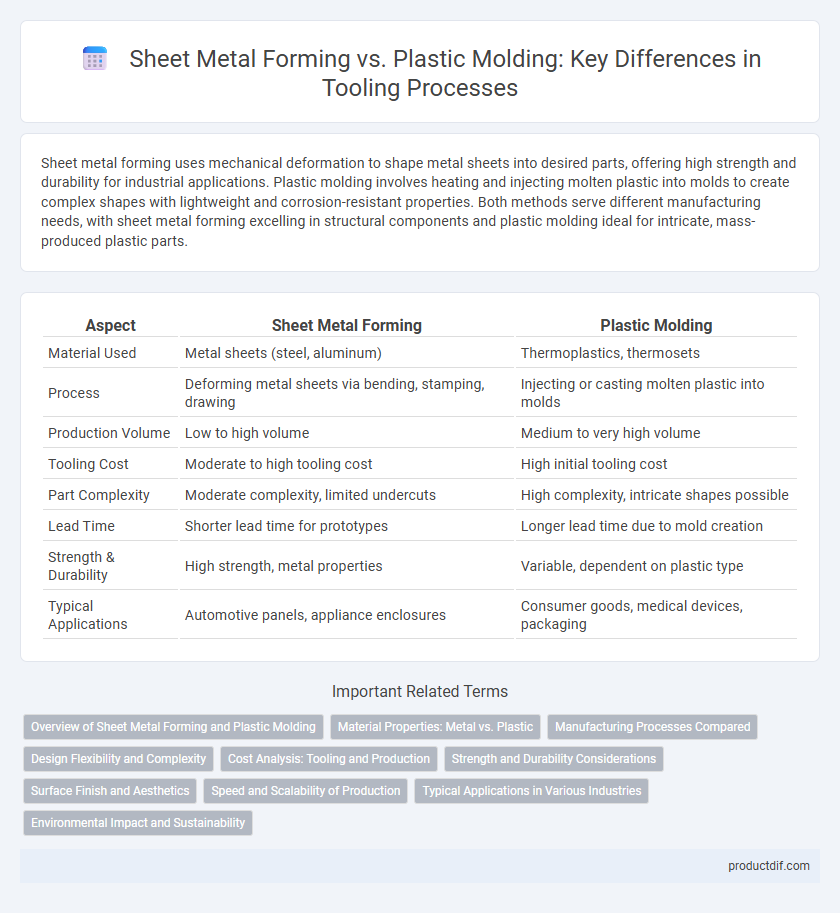

Sheet metal forming uses mechanical deformation to shape metal sheets into desired parts, offering high strength and durability for industrial applications. Plastic molding involves heating and injecting molten plastic into molds to create complex shapes with lightweight and corrosion-resistant properties. Both methods serve different manufacturing needs, with sheet metal forming excelling in structural components and plastic molding ideal for intricate, mass-produced plastic parts.

Table of Comparison

| Aspect | Sheet Metal Forming | Plastic Molding |

|---|---|---|

| Material Used | Metal sheets (steel, aluminum) | Thermoplastics, thermosets |

| Process | Deforming metal sheets via bending, stamping, drawing | Injecting or casting molten plastic into molds |

| Production Volume | Low to high volume | Medium to very high volume |

| Tooling Cost | Moderate to high tooling cost | High initial tooling cost |

| Part Complexity | Moderate complexity, limited undercuts | High complexity, intricate shapes possible |

| Lead Time | Shorter lead time for prototypes | Longer lead time due to mold creation |

| Strength & Durability | High strength, metal properties | Variable, dependent on plastic type |

| Typical Applications | Automotive panels, appliance enclosures | Consumer goods, medical devices, packaging |

Overview of Sheet Metal Forming and Plastic Molding

Sheet metal forming involves shaping metal sheets through processes such as bending, stamping, and deep drawing, enabling precise and durable components in automotive, aerospace, and appliance industries. Plastic molding, including injection, compression, and blow molding, uses heated plastic resins to produce complex, lightweight parts with high-volume production efficiency in packaging, consumer goods, and automotive sectors. Both methods optimize material properties and design flexibility but differ fundamentally in mechanics and applications, making them suitable for distinct manufacturing requirements.

Material Properties: Metal vs. Plastic

Sheet metal forming relies on the ductility and strength of metals like steel and aluminum to withstand deformation without fracturing, enabling the creation of durable, structural components. Plastic molding exploits the thermoplastic properties of materials such as polypropylene and ABS, allowing for intricate shapes and flexibility through controlled melting and cooling processes. Metal's high tensile strength and thermal conductivity differ significantly from plastic's lower density and insulation capability, influencing selection based on the application's mechanical and thermal requirements.

Manufacturing Processes Compared

Sheet metal forming utilizes mechanical deformation to shape metal sheets into desired structures, offering high strength and durability for automotive and aerospace components. Plastic molding, including injection molding and blow molding, enables the mass production of complex shapes with lightweight properties by injecting molten plastic into molds. Manufacturing efficiency depends on material selection, production volume, and design complexity, with sheet metal favoring metal parts in moderate volumes and plastic molding excelling in high-volume, intricate plastic components.

Design Flexibility and Complexity

Sheet metal forming offers higher design flexibility for parts with thin walls and structural strength, enabling complex geometries through bending, stretching, and drawing processes. Plastic molding excels in producing intricate, detailed shapes with undercuts and internal features, benefiting from mold design variations such as injection or blow molding. Selecting between sheet metal forming and plastic molding depends on the required complexity level, material properties, and production volume considerations.

Cost Analysis: Tooling and Production

Sheet metal forming typically involves higher initial tooling costs due to the need for durable dies and presses capable of handling metal deformation, whereas plastic molding requires expensive molds but often benefits from faster cycle times in mass production. Production costs in sheet metal forming are influenced by material thickness and complexity, leading to higher energy consumption and potential waste, while plastic molding offers lower per-unit costs with efficient material usage and scalability. Choosing between these methods depends on volume requirements, with sheet metal forming favored for moderate runs and plastic molding optimized for large-scale production to amortize tooling expenses.

Strength and Durability Considerations

Sheet metal forming produces parts with high tensile strength and excellent resistance to wear, making them suitable for applications requiring structural integrity and long-term durability. Plastic molding offers flexibility in design and corrosion resistance but generally results in components with lower mechanical strength compared to metal-formed parts. Strength and durability considerations often favor sheet metal forming for load-bearing and industrial tools, while plastic molding is preferred for lightweight, chemically resistant tool components.

Surface Finish and Aesthetics

Sheet metal forming typically produces parts with a smooth, metallic surface finish that highlights the natural sheen of the metal, offering high durability and excellent resistance to wear and corrosion. Plastic molding allows for greater flexibility in aesthetics, enabling intricate textures, vibrant colors, and glossy finishes that can be molded directly into the product, ideal for consumer goods requiring detailed visual appeal. Surface finish quality in sheet metal forming is influenced by factors like die condition and lubrication, while plastic molding achieves consistent aesthetics through precise mold design and material selection.

Speed and Scalability of Production

Sheet metal forming offers high-speed production suitable for large-scale manufacturing runs with rapid cycle times and minimal setup changes. Plastic molding, particularly injection molding, excels in scalability by efficiently producing complex parts in massive volumes once the mold is created, though initial tooling takes longer. Both methods support scalable production, but sheet metal forming is typically faster for simpler geometries while plastic molding scales better for intricate designs.

Typical Applications in Various Industries

Sheet metal forming is extensively used in automotive manufacturing for producing body panels, structural components, and exhaust systems due to its durability and precision. Plastic molding finds widespread application in consumer electronics, medical devices, and packaging industries, offering flexibility in complex shapes and lightweight parts. Both processes serve critical roles in aerospace and industrial equipment fabrication, optimizing performance and cost-efficiency based on material and design requirements.

Environmental Impact and Sustainability

Sheet metal forming generates less waste compared to plastic molding, as metal scraps can be recycled efficiently, reducing landfill contributions. Plastic molding often relies on non-biodegradable polymers derived from fossil fuels, raising concerns about carbon emissions and microplastic pollution. Sustainable practices in sheet metal forming include using recycled metals and energy-efficient machines, while plastic molding requires advancements in biodegradable polymers and improved waste management to minimize its environmental footprint.

Sheet Metal Forming vs Plastic Molding Infographic

productdif.com

productdif.com