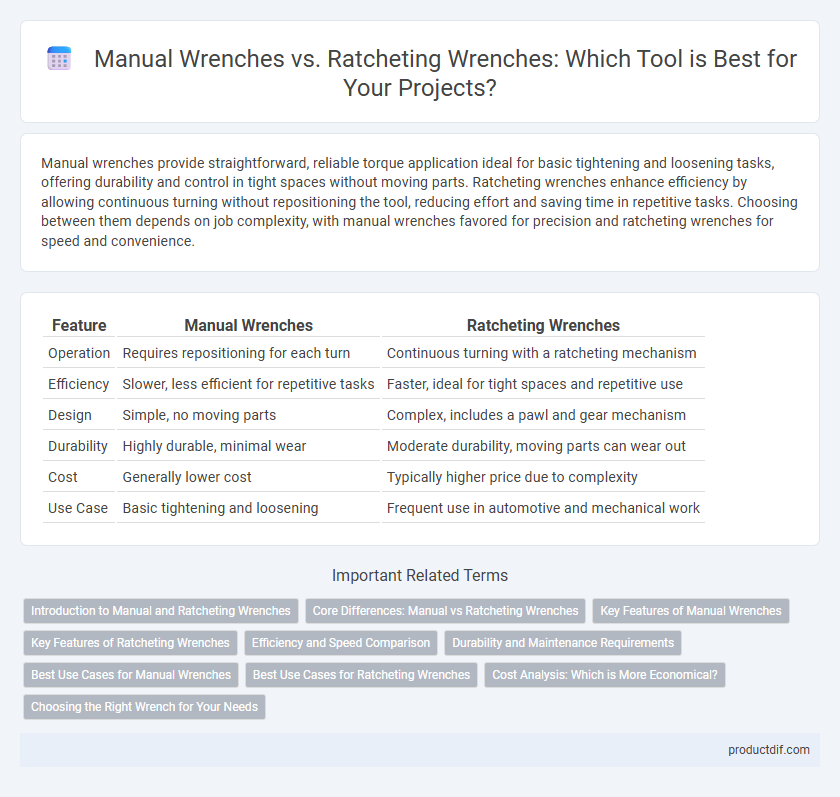

Manual wrenches provide straightforward, reliable torque application ideal for basic tightening and loosening tasks, offering durability and control in tight spaces without moving parts. Ratcheting wrenches enhance efficiency by allowing continuous turning without repositioning the tool, reducing effort and saving time in repetitive tasks. Choosing between them depends on job complexity, with manual wrenches favored for precision and ratcheting wrenches for speed and convenience.

Table of Comparison

| Feature | Manual Wrenches | Ratcheting Wrenches |

|---|---|---|

| Operation | Requires repositioning for each turn | Continuous turning with a ratcheting mechanism |

| Efficiency | Slower, less efficient for repetitive tasks | Faster, ideal for tight spaces and repetitive use |

| Design | Simple, no moving parts | Complex, includes a pawl and gear mechanism |

| Durability | Highly durable, minimal wear | Moderate durability, moving parts can wear out |

| Cost | Generally lower cost | Typically higher price due to complexity |

| Use Case | Basic tightening and loosening | Frequent use in automotive and mechanical work |

Introduction to Manual and Ratcheting Wrenches

Manual wrenches provide a straightforward mechanism for tightening or loosening bolts by applying direct torque, offering reliability in various mechanical tasks. Ratcheting wrenches incorporate a built-in ratchet mechanism that allows continuous motion without repositioning, enhancing efficiency in tight spaces. Both tools are essential in automotive, construction, and home repair applications, each delivering specific advantages based on accessibility and speed requirements.

Core Differences: Manual vs Ratcheting Wrenches

Manual wrenches require repositioning after each turn, providing precise torque control and durability without mechanical parts. Ratcheting wrenches feature an internal ratchet mechanism that allows continuous rotation without removing the tool, increasing efficiency in tight spaces. The core difference lies in manual wrenches offering simplicity and reliability, while ratcheting wrenches enhance speed and convenience for repetitive tasks.

Key Features of Manual Wrenches

Manual wrenches feature a simple, fixed design that provides reliable torque for tightening and loosening fasteners, making them ideal for basic mechanical tasks. Their open-end and box-end variants offer versatility when accessing tight spaces or handling stubborn bolts. The lack of moving parts ensures durability and ease of maintenance, which enhances their longevity in various work environments.

Key Features of Ratcheting Wrenches

Ratcheting wrenches feature a built-in ratchet mechanism that allows continuous turning without removing the tool from the fastener, significantly speeding up work processes. Their slim profile and reversible ratchet enable use in tight spaces and flexibility in direction, unlike manual wrenches which require frequent repositioning. High-quality ratcheting wrenches often include precision-tooth gears for smooth operation and durability, making them essential for automotive and mechanical tasks.

Efficiency and Speed Comparison

Manual wrenches require repositioning after each turn, which can slow down tasks in tight spaces, whereas ratcheting wrenches allow continuous motion without removing the tool, significantly increasing efficiency and speed. Ratcheting mechanisms reduce the effort needed for repetitive tightening or loosening, making them ideal for high-volume or time-sensitive projects. For professionals seeking faster turnaround times, ratcheting wrenches provide a measurable advantage in both performance and productivity.

Durability and Maintenance Requirements

Manual wrenches typically offer superior durability due to their simple, solid construction with fewer moving parts subject to wear. Ratcheting wrenches feature more complex mechanisms that require regular maintenance, such as cleaning and lubrication, to prevent gear wear and ensure smooth operation. Proper upkeep of ratcheting wrenches extends their lifespan but generally cannot match the long-term robustness of standard manual wrenches.

Best Use Cases for Manual Wrenches

Manual wrenches excel in situations requiring precise torque control and minimal risk of over-tightening, such as plumbing repairs and delicate mechanical assemblies. Their simple, robust design makes them ideal for tight spaces where ratcheting mechanisms might jam or fail. Handymen and professionals prefer manual wrenches for fasteners that demand high leverage and steady, controlled force.

Best Use Cases for Ratcheting Wrenches

Ratcheting wrenches excel in tight spaces where continuous rotation without repositioning is essential, making them ideal for automotive repairs and machinery maintenance. Their built-in ratchet mechanism speeds up fastening and loosening bolts, reducing hand fatigue during repetitive tasks. These wrenches offer efficiency in confined environments where traditional manual wrenches may require frequent adjustments, improving overall workflow.

Cost Analysis: Which is More Economical?

Manual wrenches typically have a lower upfront cost compared to ratcheting wrenches, making them more economical for basic tasks or infrequent use. Ratcheting wrenches, while initially more expensive, offer increased efficiency and speed, potentially saving labor costs in professional settings. Over time, the durability and time-saving features of ratcheting wrenches may justify the higher investment for regular users.

Choosing the Right Wrench for Your Needs

Manual wrenches provide precise torque control and are ideal for simple, straightforward tasks requiring steady pressure, while ratcheting wrenches offer speed and efficiency in tight spaces by allowing continuous turning without removing the tool. Consider the working environment: manual wrenches excel in durability and reliability for heavy-duty jobs, whereas ratcheting wrenches increase productivity in automotive and assembly applications. Selecting the right wrench depends on task complexity, space constraints, and the need for speed versus control.

Manual wrenches vs Ratcheting wrenches Infographic

productdif.com

productdif.com