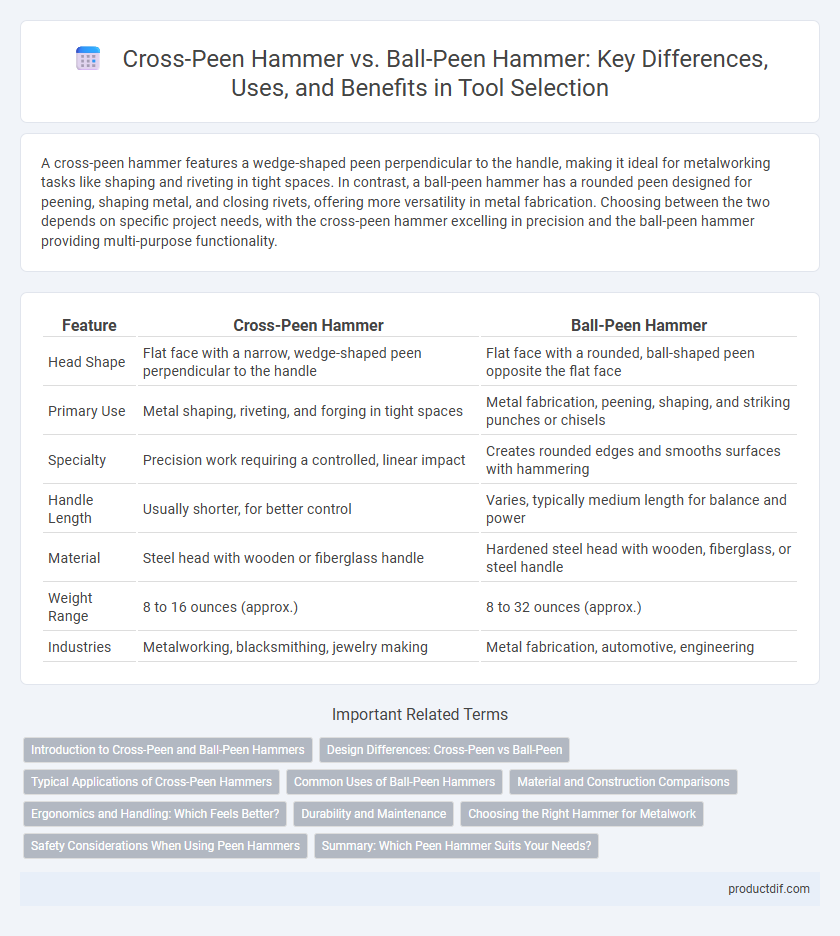

A cross-peen hammer features a wedge-shaped peen perpendicular to the handle, making it ideal for metalworking tasks like shaping and riveting in tight spaces. In contrast, a ball-peen hammer has a rounded peen designed for peening, shaping metal, and closing rivets, offering more versatility in metal fabrication. Choosing between the two depends on specific project needs, with the cross-peen hammer excelling in precision and the ball-peen hammer providing multi-purpose functionality.

Table of Comparison

| Feature | Cross-Peen Hammer | Ball-Peen Hammer |

|---|---|---|

| Head Shape | Flat face with a narrow, wedge-shaped peen perpendicular to the handle | Flat face with a rounded, ball-shaped peen opposite the flat face |

| Primary Use | Metal shaping, riveting, and forging in tight spaces | Metal fabrication, peening, shaping, and striking punches or chisels |

| Specialty | Precision work requiring a controlled, linear impact | Creates rounded edges and smooths surfaces with hammering |

| Handle Length | Usually shorter, for better control | Varies, typically medium length for balance and power |

| Material | Steel head with wooden or fiberglass handle | Hardened steel head with wooden, fiberglass, or steel handle |

| Weight Range | 8 to 16 ounces (approx.) | 8 to 32 ounces (approx.) |

| Industries | Metalworking, blacksmithing, jewelry making | Metal fabrication, automotive, engineering |

Introduction to Cross-Peen and Ball-Peen Hammers

Cross-peen hammers feature a wedge-shaped peen perpendicular to the handle, making them ideal for metal shaping and riveting tasks. Ball-peen hammers have a rounded peen opposite the flat face, designed primarily for metalworking applications such as peening and striking punches or chisels. Both hammers play essential roles in workshops, with distinct shapes tailored to specific functions in metal fabrication and repair.

Design Differences: Cross-Peen vs Ball-Peen

Cross-peen hammers feature a wedge-shaped peen positioned perpendicular to the handle, enabling precise metal shaping and riveting tasks by directing force along a narrow edge. Ball-peen hammers have a rounded, hemispherical peen designed for peening rivets, shaping metal, and creating smooth, curved surfaces in metalworking. The distinct peen shapes affect impact distribution and application, making cross-peen hammers ideal for spreading metal sideways and ball-peen hammers suited for rounding and texturing.

Typical Applications of Cross-Peen Hammers

Cross-peen hammers are commonly used for metalworking tasks such as shaping and forging because their wedge-shaped peen allows precise control when spreading metal. These hammers are ideal for riveting, panel beating, and blacksmithing where directional force is necessary. Unlike ball-peen hammers, cross-peen hammers excel in creating narrow, elongated indentations in metal surfaces.

Common Uses of Ball-Peen Hammers

Ball-peen hammers are predominantly used in metalworking tasks such as shaping metal, riveting, and peening to harden surfaces. Their rounded peen is ideal for smoothing out rough edges and expanding rivet heads. Unlike cross-peen hammers, which excel in woodworking and striking chisels, ball-peen hammers specialize in precision metal fabrication and maintenance.

Material and Construction Comparisons

Cross-peen hammers typically feature a forged steel head with a flat striking face and a wedge-shaped peen, optimized for metal shaping and riveting tasks requiring precise control. Ball-peen hammers contain a hardened steel head with one flat face and one rounded, ball-shaped peen designed for peening metal and shaping rounded surfaces, providing durability and resistance to deformation. Both hammers often have wooden or fiberglass handles for shock absorption, but the choice of steel hardness and head geometry directly impacts their suitability for specific metalworking applications.

Ergonomics and Handling: Which Feels Better?

A cross-peen hammer offers superior control for precision tasks due to its narrow, flat peen, promoting better grip and reduced wrist strain during extended use. Ball-peen hammers feature a rounded peen that balances weight distribution, enhancing overall handling comfort and shock absorption. Ergonomically, users often find the cross-peen hammer more suitable for detailed metalwork, while the ball-peen hammer excels in general-purpose applications with cushioned impact feedback.

Durability and Maintenance

Cross-peen hammers offer superior durability due to their robust forged steel heads that resist wear and deformation under heavy use. Ball-peen hammers feature hardened steel heads but may require more frequent maintenance to prevent chipping, especially when used on hard metals. Regular inspection and proper storage significantly extend the lifespan of both hammer types by minimizing rust and head damage.

Choosing the Right Hammer for Metalwork

Choosing the right hammer for metalwork depends on the specific task: a cross-peen hammer features a wedge-shaped peen ideal for shaping metal and creating precise seams, while a ball-peen hammer is better suited for rounding off edges and striking punches and chisels. The cross-peen hammer provides greater control in metal forming and riveting, often preferred by blacksmiths and metalworkers who require detailed shaping. In contrast, ball-peen hammers excel in metal fabrication tasks involving peening and surface work where a smooth, rounded impact is essential.

Safety Considerations When Using Peen Hammers

When using cross-peen and ball-peen hammers, wearing safety goggles protects eyes from flying debris caused by metal striking. Choosing hammers with secure, shock-absorbing handles reduces the risk of hand injuries and improves grip stability. Inspecting the hammer for cracks or loose heads before use prevents accidental detachment and ensures safe operation.

Summary: Which Peen Hammer Suits Your Needs?

Cross-peen hammers offer precise control for metal shaping and riveting, making them ideal for blacksmithing and detailed metalwork. Ball-peen hammers excel in metal fabrication tasks like peening and rounding off edges, preferred in automotive and engineering workshops. Choosing between the two depends on whether your project requires fine metal manipulation or heavy-duty forging and shaping.

cross-peen hammer vs ball-peen hammer Infographic

productdif.com

productdif.com