A hammer drill excels at drilling into hard materials like concrete and masonry by combining rotary motion with a hammering action, making it ideal for heavy-duty construction tasks. An impact driver delivers high torque through rapid concussive bursts, perfect for driving screws and bolts quickly without stripping them. Choosing between a hammer drill and an impact driver depends on whether the primary task involves drilling into tough surfaces or fastening hardware efficiently.

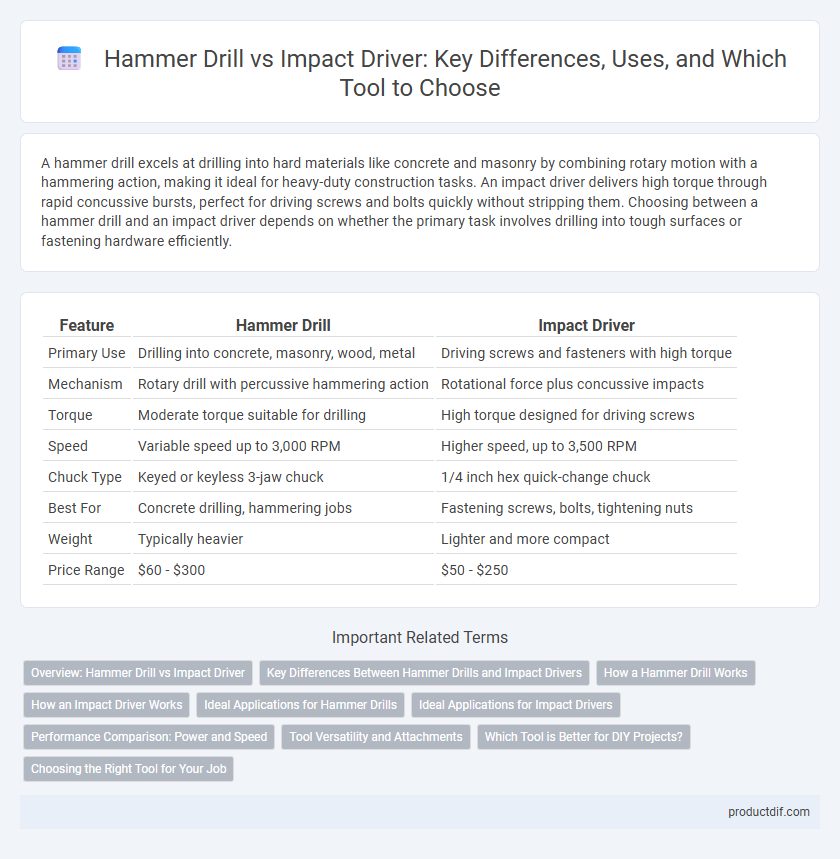

Table of Comparison

| Feature | Hammer Drill | Impact Driver |

|---|---|---|

| Primary Use | Drilling into concrete, masonry, wood, metal | Driving screws and fasteners with high torque |

| Mechanism | Rotary drill with percussive hammering action | Rotational force plus concussive impacts |

| Torque | Moderate torque suitable for drilling | High torque designed for driving screws |

| Speed | Variable speed up to 3,000 RPM | Higher speed, up to 3,500 RPM |

| Chuck Type | Keyed or keyless 3-jaw chuck | 1/4 inch hex quick-change chuck |

| Best For | Concrete drilling, hammering jobs | Fastening screws, bolts, tightening nuts |

| Weight | Typically heavier | Lighter and more compact |

| Price Range | $60 - $300 | $50 - $250 |

Overview: Hammer Drill vs Impact Driver

Hammer drills deliver rotary drilling with a pulsating hammering action ideal for drilling into masonry, concrete, and stone, combining high torque with percussive force. Impact drivers provide high-torque rotational impacts for driving screws and bolts efficiently, excelling in fastening tasks with quick bursts of concussive force. Understanding their distinct mechanisms and optimal applications guides users in selecting the right tool for construction, woodworking, or home improvement projects.

Key Differences Between Hammer Drills and Impact Drivers

Hammer drills deliver rapid hammering action combined with rotary motion, making them ideal for drilling into masonry and concrete. Impact drivers provide high torque through concussive rotational impacts, which excels at driving screws and fastening applications. The key difference lies in their mechanism and purpose: hammer drills focus on drilling holes with hammering force, while impact drivers specialize in driving screws with rotational impacts.

How a Hammer Drill Works

A hammer drill uses a rapid hammering action combined with rotary drilling to penetrate tough materials like concrete and masonry. This tool features a piston mechanism that creates a pulsating force, enabling the drill bit to chip away while it spins. The simultaneous hammering and drilling action makes the hammer drill ideal for heavy-duty construction and remodeling projects.

How an Impact Driver Works

An impact driver works by combining rotational force with concussive blows to drive screws and bolts more efficiently than a traditional drill. It uses a spring, hammer, and anvil mechanism inside the tool to deliver high torque in short bursts, making it ideal for heavy-duty fastening tasks. This design reduces user fatigue and prevents stripping screws, especially in tough materials like hardwood and metal.

Ideal Applications for Hammer Drills

Hammer drills excel in masonry and concrete applications, providing powerful percussive force combined with rotational drilling to efficiently bore into tough materials. Ideal for installing anchors, drilling holes for rebar, and driving screws into brick or stone surfaces. Their versatility makes them essential for construction, renovation, and heavy-duty DIY projects involving dense substrates.

Ideal Applications for Impact Drivers

Impact drivers excel in driving long screws, lag bolts, and fasteners into tough materials like hardwood and metal due to their high torque and rapid rotational impacts. They are ideal for heavy-duty fastening tasks such as deck building, framing, and automotive repairs where precision and power are necessary. Their compact design and efficient energy transfer make them preferred for repetitive screw driving in confined spaces.

Performance Comparison: Power and Speed

Hammer drills deliver high impact energy suitable for drilling into hard materials like concrete, typically providing 1,000 to 3,000 RPM with hammering action around 20,000 BPM (blows per minute). Impact drivers excel in torque, often generating 1,500 to 2,000 in-lbs of torque at speeds between 2,000 and 3,500 RPM, making them ideal for driving large fasteners quickly. Choosing between the two depends on the task requirements: hammer drills prioritize power for masonry drilling, while impact drivers focus on speed and torque for fastening applications.

Tool Versatility and Attachments

A hammer drill offers exceptional versatility with its ability to switch between rotary drilling and hammering action, making it ideal for drilling into concrete, wood, and metal using various drill bits. Impact drivers excel in delivering high torque for driving screws and bolts, featuring a quick-change chuck compatible with a wide range of hex-shank screwdriver bits and attachments. Choosing between these tools depends on the specific job: the hammer drill supports diverse drilling and light chiseling tasks, while the impact driver is optimized for fastening and driving applications requiring rapid, powerful torque.

Which Tool is Better for DIY Projects?

Hammer drills deliver powerful rotary hammering, making them ideal for drilling into masonry and concrete for DIY projects that require precision and strength. Impact drivers excel at driving screws and bolts with high torque, offering efficiency when assembling furniture or framing. Choosing between a hammer drill and an impact driver depends on project requirements, where the hammer drill is better suited for heavy-duty drilling and the impact driver for fast, reliable fastening.

Choosing the Right Tool for Your Job

Selecting between a hammer drill and an impact driver depends on the specific task requirements and material. Hammer drills excel in drilling into masonry and concrete with their percussive action, while impact drivers provide high torque for driving screws and fasteners in wood and metal. Understanding the distinct functionalities ensures efficient and precise tool use, enhancing project outcomes and reducing wear.

Hammer Drill vs Impact Driver Infographic

productdif.com

productdif.com