An impact driver delivers high torque and rotational force ideal for driving screws and bolts quickly, especially in tough materials, while a drill provides versatile drilling capabilities with variable speed settings for different materials. Impact drivers typically have a hex chuck for quick bit changes, enhancing efficiency in fastening tasks compared to the traditional chuck of a drill. Choosing between them depends on whether your priority is powerful fastening or flexible drilling and driving.

Table of Comparison

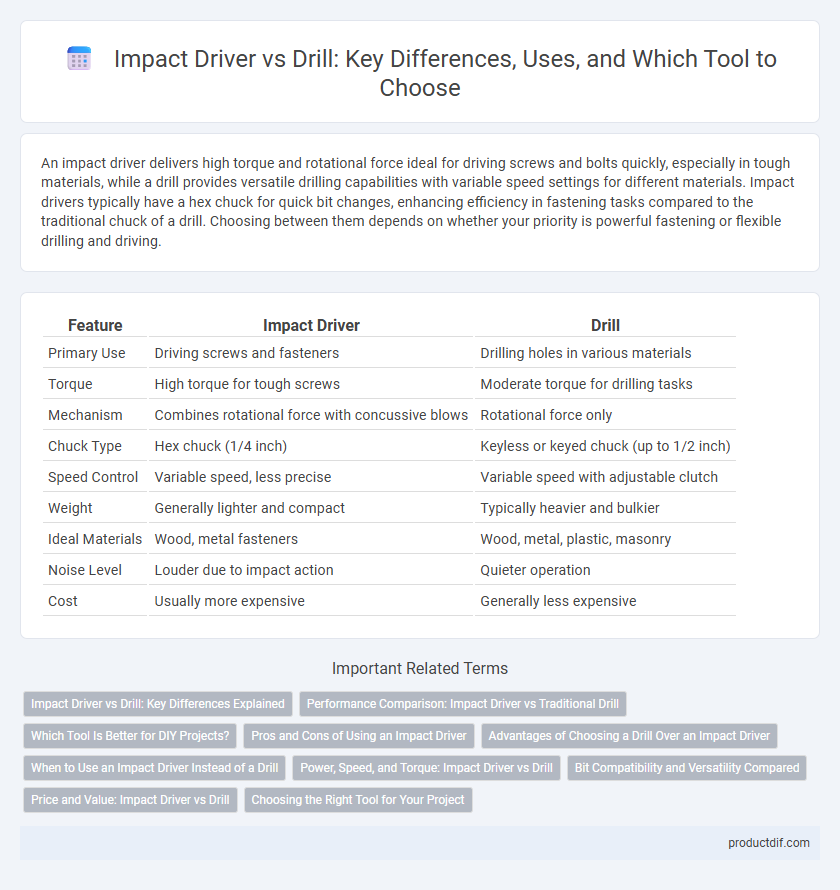

| Feature | Impact Driver | Drill |

|---|---|---|

| Primary Use | Driving screws and fasteners | Drilling holes in various materials |

| Torque | High torque for tough screws | Moderate torque for drilling tasks |

| Mechanism | Combines rotational force with concussive blows | Rotational force only |

| Chuck Type | Hex chuck (1/4 inch) | Keyless or keyed chuck (up to 1/2 inch) |

| Speed Control | Variable speed, less precise | Variable speed with adjustable clutch |

| Weight | Generally lighter and compact | Typically heavier and bulkier |

| Ideal Materials | Wood, metal fasteners | Wood, metal, plastic, masonry |

| Noise Level | Louder due to impact action | Quieter operation |

| Cost | Usually more expensive | Generally less expensive |

Impact Driver vs Drill: Key Differences Explained

Impact drivers deliver high torque through rapid concussive blows, making them ideal for driving large fasteners and loosening tough bolts, whereas drills provide consistent rotational force suited for drilling holes and driving smaller screws. Impact drivers typically feature a hex collet for quick bit changes and excel in applications requiring power and speed, while drills use a chuck that accommodates a wide variety of drill bits for versatile tasks. Choosing between the two depends on the specific needs of your project, with impact drivers favored for heavy-duty fastening and drills preferred for precision drilling and general-use scenarios.

Performance Comparison: Impact Driver vs Traditional Drill

Impact drivers deliver higher torque and faster fastening speeds compared to traditional drills, making them ideal for heavy-duty tasks like driving large screws and bolts. Traditional drills offer more versatility with adjustable speed settings and better control for precise drilling in wood, metal, and plastic. While impact drivers excel in efficiency for repetitive fastening, drills provide superior performance in hole-making and light-duty applications.

Which Tool Is Better for DIY Projects?

An impact driver delivers higher torque and better performance for driving screws and bolts into tough materials, making it ideal for heavy-duty DIY projects. Drills provide versatile functionality, suitable for drilling holes and light to medium screwdriving tasks, offering greater precision and control for detailed work. Choosing between an impact driver and a drill depends on the project requirements, with impact drivers excelling in power and drills excelling in versatility.

Pros and Cons of Using an Impact Driver

Impact drivers excel in delivering high torque, making them ideal for driving long screws and dense materials without stripping the screw head. Their compact design allows for better control in tight spaces, though they typically lack the precision and versatility of drills for tasks like drilling holes in softer materials. While impact drivers are powerful and efficient for fastening, they may produce more noise and vibration, which can be fatiguing during extended use.

Advantages of Choosing a Drill Over an Impact Driver

A drill offers greater versatility, capable of performing both drilling and light driving tasks, making it suitable for various materials such as wood, metal, and plastic. It provides more control over speed and torque, allowing for precise hole sizes and clean finishes. Drills typically have adjustable clutch settings, preventing overdriving screws and reducing the risk of damaging workpieces, ideal for delicate projects.

When to Use an Impact Driver Instead of a Drill

Choose an impact driver instead of a drill when working with tough fasteners like screws, bolts, or lag nuts, as it delivers higher torque and prevents stripping. Impact drivers excel in driving long screws into dense materials such as hardwood or metal, making them indispensable for heavy-duty fastening tasks. Use drills primarily for boring holes or light fastening, while impact drivers offer superior performance for repetitive screw-driving jobs.

Power, Speed, and Torque: Impact Driver vs Drill

Impact drivers deliver high torque and rapid rotational bursts designed for driving screws and bolts efficiently, ideal for heavy-duty fastening tasks. Drills offer consistent speed and moderate torque, making them versatile for drilling holes and light fastening in various materials. Power tools like impact drivers are optimized for torque and speed bursts, while drills emphasize stable performance across different applications.

Bit Compatibility and Versatility Compared

Impact drivers and drills differ significantly in bit compatibility and versatility, with impact drivers primarily designed for hex-shank bits, allowing quick bit changes and superior torque for driving screws, nuts, and fasteners. Drills feature a keyless chuck that accepts round and hex shanks, enabling use with a wider variety of bits including drill bits, hole saws, and sanding attachments, which enhances their functionality for drilling and light driving tasks. Choosing between the two depends on whether the application requires high torque with specialized fastener bits or broad versatility for multiple drilling and driving jobs.

Price and Value: Impact Driver vs Drill

Impact drivers typically cost between $70 and $150, offering high torque ideal for heavy-duty tasks like driving long screws and bolts, providing excellent value for construction professionals. Drills range from $50 to $200, delivering versatility for drilling holes and light fastening, making them a cost-effective choice for general DIY projects. When comparing price and value, impact drivers excel in power and efficiency for fastening, while drills offer broader functionality at a competitive price point.

Choosing the Right Tool for Your Project

Impact drivers deliver high torque ideal for driving large fasteners and heavy-duty projects, while drills provide versatility for drilling holes and lighter fastening tasks. Selecting the right tool depends on your project's requirements: use an impact driver for tough materials and high-torque applications, and choose a drill for precision hole drilling or light-duty screwing. Understanding the power, speed, and bit compatibility differences ensures efficient tool performance and project success.

Impact Driver vs Drill Infographic

productdif.com

productdif.com