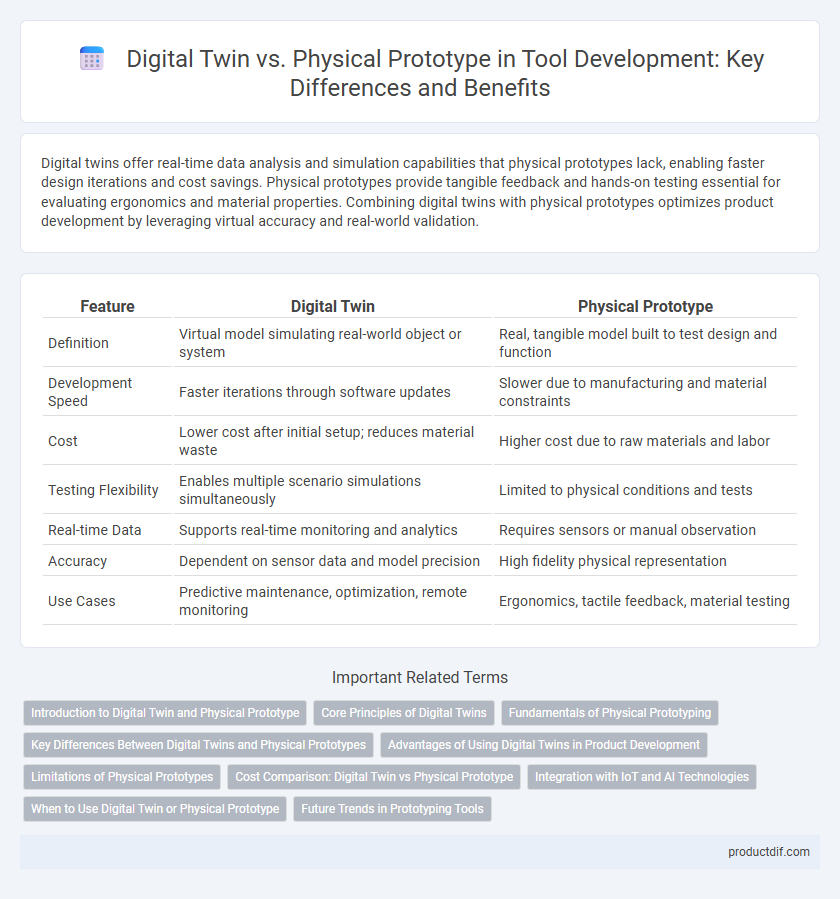

Digital twins offer real-time data analysis and simulation capabilities that physical prototypes lack, enabling faster design iterations and cost savings. Physical prototypes provide tangible feedback and hands-on testing essential for evaluating ergonomics and material properties. Combining digital twins with physical prototypes optimizes product development by leveraging virtual accuracy and real-world validation.

Table of Comparison

| Feature | Digital Twin | Physical Prototype |

|---|---|---|

| Definition | Virtual model simulating real-world object or system | Real, tangible model built to test design and function |

| Development Speed | Faster iterations through software updates | Slower due to manufacturing and material constraints |

| Cost | Lower cost after initial setup; reduces material waste | Higher cost due to raw materials and labor |

| Testing Flexibility | Enables multiple scenario simulations simultaneously | Limited to physical conditions and tests |

| Real-time Data | Supports real-time monitoring and analytics | Requires sensors or manual observation |

| Accuracy | Dependent on sensor data and model precision | High fidelity physical representation |

| Use Cases | Predictive maintenance, optimization, remote monitoring | Ergonomics, tactile feedback, material testing |

Introduction to Digital Twin and Physical Prototype

Digital twin technology creates a virtual replica of a physical object or system, enabling real-time monitoring, simulation, and analysis to optimize performance and predict maintenance needs. Physical prototypes serve as tangible models for testing design concepts, functionality, and ergonomics before full-scale production. Comparing these, digital twins offer dynamic, data-driven insights while physical prototypes provide hands-on evaluation.

Core Principles of Digital Twins

Digital twins operate by creating dynamic, real-time virtual replicas of physical prototypes using sensor data and advanced analytics to simulate performance and predict outcomes. Unlike static physical prototypes, digital twins leverage continuous data integration, enabling iterative testing and optimization without physical resource constraints. This core principle enhances accuracy in design validation, reduces development costs, and accelerates time-to-market across manufacturing and engineering domains.

Fundamentals of Physical Prototyping

Physical prototyping involves creating tangible models that replicate the design and functionality of a product, enabling direct testing and validation of materials, form, and usability. It provides critical insights into manufacturing processes and mechanical performance that are difficult to capture through digital means alone. This hands-on approach remains essential for detecting design flaws and ensuring ergonomic feasibility before mass production.

Key Differences Between Digital Twins and Physical Prototypes

Digital twins offer real-time, data-driven simulations that enable continuous monitoring and predictive maintenance, while physical prototypes provide tangible models used for hands-on testing and validation. Unlike physical prototypes, digital twins integrate IoT sensors and digital analytics to replicate dynamic system behavior without material costs or fabrication time. The key difference lies in the digital twin's ability to update and optimize products virtually throughout the lifecycle versus the static nature of physical prototypes limited to initial design stages.

Advantages of Using Digital Twins in Product Development

Digital twins enable real-time simulation and testing of products, reducing the need for costly physical prototypes and accelerating the development cycle. They provide precise data analytics and predictive maintenance insights, enhancing product performance and reliability. Virtual modeling with digital twins allows for iterative design improvements, minimizing errors and enabling faster innovation in product development.

Limitations of Physical Prototypes

Physical prototypes often face limitations such as high production costs, extended development times, and restricted scalability for multiple iterations. They lack real-time data integration and are unable to simulate dynamic environmental conditions accurately. These constraints hinder rapid design optimization and delay time-to-market compared to digital twin models.

Cost Comparison: Digital Twin vs Physical Prototype

Digital twins significantly reduce costs compared to physical prototypes by minimizing the need for multiple material samples and costly iterations. Physical prototypes often incur higher expenses due to manufacturing, labor, and material waste, whereas digital twins enable virtual testing and real-time adjustments without additional physical resources. This cost efficiency accelerates development cycles and lowers overall project budgets in engineering and manufacturing processes.

Integration with IoT and AI Technologies

Digital twins leverage seamless integration with IoT sensors to collect real-time data, enabling continuous monitoring and predictive analysis that physical prototypes cannot achieve. AI algorithms process this data to simulate various scenarios, optimize performance, and identify potential failures before they occur. This fusion of IoT and AI transforms digital twins into dynamic, adaptive models, surpassing static physical prototypes in efficiency and innovation.

When to Use Digital Twin or Physical Prototype

Digital twins excel in scenarios requiring real-time data analysis, continuous monitoring, and predictive maintenance, especially in complex systems like manufacturing or aerospace. Physical prototypes remain essential for initial product validation, tactile feedback, and testing material properties under real-world conditions. Combining both approaches enhances design accuracy and reduces time-to-market in product development cycles.

Future Trends in Prototyping Tools

Future trends in prototyping tools emphasize the integration of digital twins with physical prototypes, enhancing real-time data synchronization and predictive analytics. Advanced simulation capabilities driven by AI and IoT enable more accurate virtual testing, reducing time-to-market and development costs. The convergence of augmented reality and cloud computing further streamlines collaboration across distributed engineering teams, fostering innovation and efficiency in product design.

Digital twin vs Physical prototype Infographic

productdif.com

productdif.com