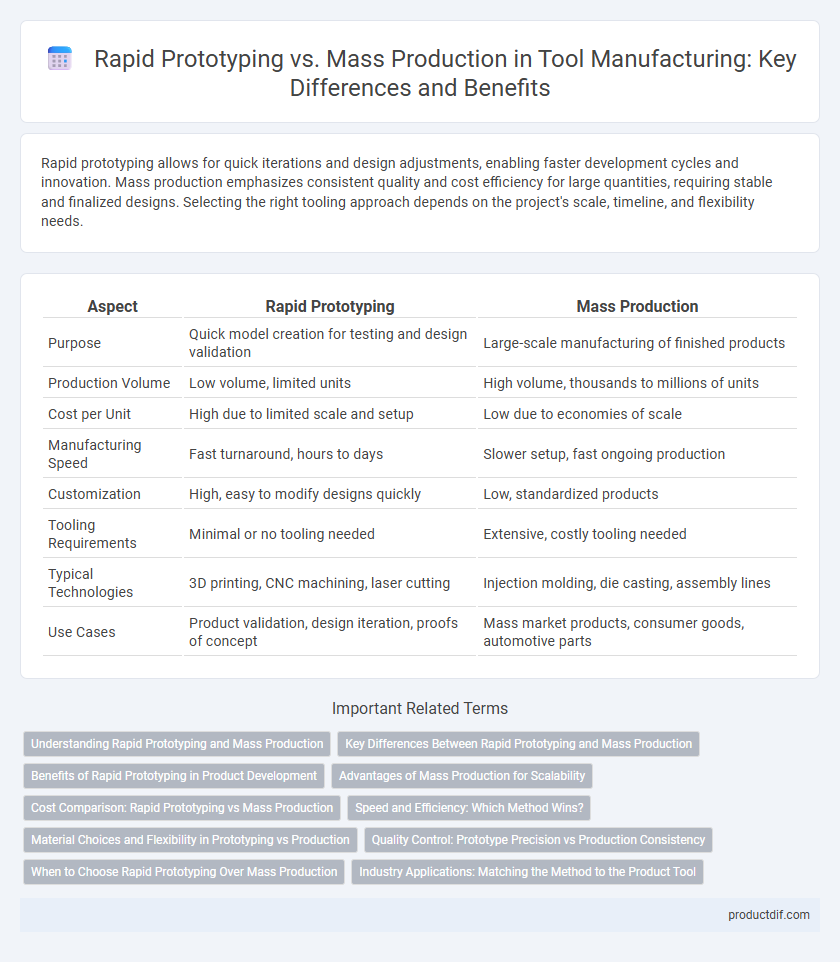

Rapid prototyping allows for quick iterations and design adjustments, enabling faster development cycles and innovation. Mass production emphasizes consistent quality and cost efficiency for large quantities, requiring stable and finalized designs. Selecting the right tooling approach depends on the project's scale, timeline, and flexibility needs.

Table of Comparison

| Aspect | Rapid Prototyping | Mass Production |

|---|---|---|

| Purpose | Quick model creation for testing and design validation | Large-scale manufacturing of finished products |

| Production Volume | Low volume, limited units | High volume, thousands to millions of units |

| Cost per Unit | High due to limited scale and setup | Low due to economies of scale |

| Manufacturing Speed | Fast turnaround, hours to days | Slower setup, fast ongoing production |

| Customization | High, easy to modify designs quickly | Low, standardized products |

| Tooling Requirements | Minimal or no tooling needed | Extensive, costly tooling needed |

| Typical Technologies | 3D printing, CNC machining, laser cutting | Injection molding, die casting, assembly lines |

| Use Cases | Product validation, design iteration, proofs of concept | Mass market products, consumer goods, automotive parts |

Understanding Rapid Prototyping and Mass Production

Rapid prototyping enables quick creation of functional models using techniques like 3D printing and CNC machining, facilitating design validation and iterative testing. Mass production involves large-scale manufacturing processes such as injection molding or automated assembly lines, optimized for efficiency, consistency, and cost reduction per unit. Understanding the difference highlights rapid prototyping's role in development phases versus mass production's emphasis on volume and scalability.

Key Differences Between Rapid Prototyping and Mass Production

Rapid prototyping enables fast iteration and design validation with minimal setup costs, using technologies like 3D printing and CNC machining to create functional models quickly. Mass production focuses on high-volume manufacturing with economies of scale, requiring substantial initial investment in tooling, molds, and assembly lines to ensure consistent product quality. The primary differences lie in production speed, cost-efficiency at scale, and flexibility in design modifications.

Benefits of Rapid Prototyping in Product Development

Rapid prototyping accelerates product development by enabling quick iterations and immediate testing, significantly reducing time-to-market. It allows designers and engineers to identify flaws early, improve design accuracy, and minimize costly errors before mass production begins. This flexibility enhances innovation and customization, making rapid prototyping an indispensable tool for agile manufacturing and product optimization.

Advantages of Mass Production for Scalability

Mass production offers unparalleled scalability by enabling the efficient manufacture of large quantities of tools at a lower cost per unit, leveraging economies of scale. Automated processes and standardized components enhance consistency and reduce production time, making it ideal for meeting high market demand. This approach also allows for streamlined supply chains, ensuring reliable availability and faster delivery to customers worldwide.

Cost Comparison: Rapid Prototyping vs Mass Production

Rapid prototyping involves higher per-unit costs due to low-volume production and use of advanced technologies like 3D printing, making it ideal for initial design validation and iterative development. Mass production significantly reduces the per-unit cost by leveraging economies of scale, automated processes, and bulk material purchasing, optimizing for large-volume output. Choosing between rapid prototyping and mass production depends on balancing upfront investment against long-term cost efficiency in manufacturing.

Speed and Efficiency: Which Method Wins?

Rapid prototyping excels in speed by enabling quick design iterations and immediate testing, significantly reducing time-to-market for new product concepts. In contrast, mass production prioritizes efficiency through economies of scale, delivering large volumes at lower unit costs but requiring longer setup times. For projects demanding swift development and flexibility, rapid prototyping is superior, while mass production dominates when consistent output and cost-efficiency are essential.

Material Choices and Flexibility in Prototyping vs Production

Rapid prototyping commonly employs versatile materials such as PLA, ABS, and resin, enabling quick adjustments and iteration of designs, while mass production relies on durable materials like injection-molded plastics, metals, or composites for consistency and long-term use. Flexibility in prototyping allows for easy modification and customization during early development stages, contrasting with mass production processes that prioritize standardized tooling and material homogeneity to maximize efficiency and reduce costs. Selecting appropriate materials in each phase impacts product performance, production speed, and overall manufacturing flexibility.

Quality Control: Prototype Precision vs Production Consistency

Rapid prototyping emphasizes high prototype precision through iterative testing and refinement, facilitating early detection of design flaws and ensuring adherence to specifications. Mass production prioritizes production consistency by implementing standardized processes and rigorous quality control measures to maintain uniformity across large quantities. The balance between prototype accuracy and manufacturing reliability is critical to optimizing both product development and scalable output quality.

When to Choose Rapid Prototyping Over Mass Production

Rapid prototyping is ideal for product development stages requiring quick design iterations and functionality testing, especially when time-to-market is critical. It enables cost-effective validation of product concepts before committing to expensive mass production tooling. Choose rapid prototyping when customization, design flexibility, and early error detection are priorities over volume and unit cost efficiency.

Industry Applications: Matching the Method to the Product Tool

Rapid prototyping excels in industries like aerospace, automotive, and medical devices where customized, low-volume tools are crucial for testing and development. Mass production suits sectors such as consumer electronics and household goods, requiring high-volume, cost-efficient tool manufacturing to meet market demands. Selecting the appropriate tool-making method depends on product complexity, production scale, and time-to-market priorities.

Rapid prototyping vs Mass production Infographic

productdif.com

productdif.com