Hand tools offer precision and control for intricate tasks, relying on manual effort and skill, making them ideal for detailed woodworking or delicate repairs. Machine tools provide higher efficiency and consistent power for shaping and cutting materials, suitable for large-scale manufacturing and heavy-duty projects. Choosing between hand and machine tools depends on the project's complexity, volume, and required accuracy.

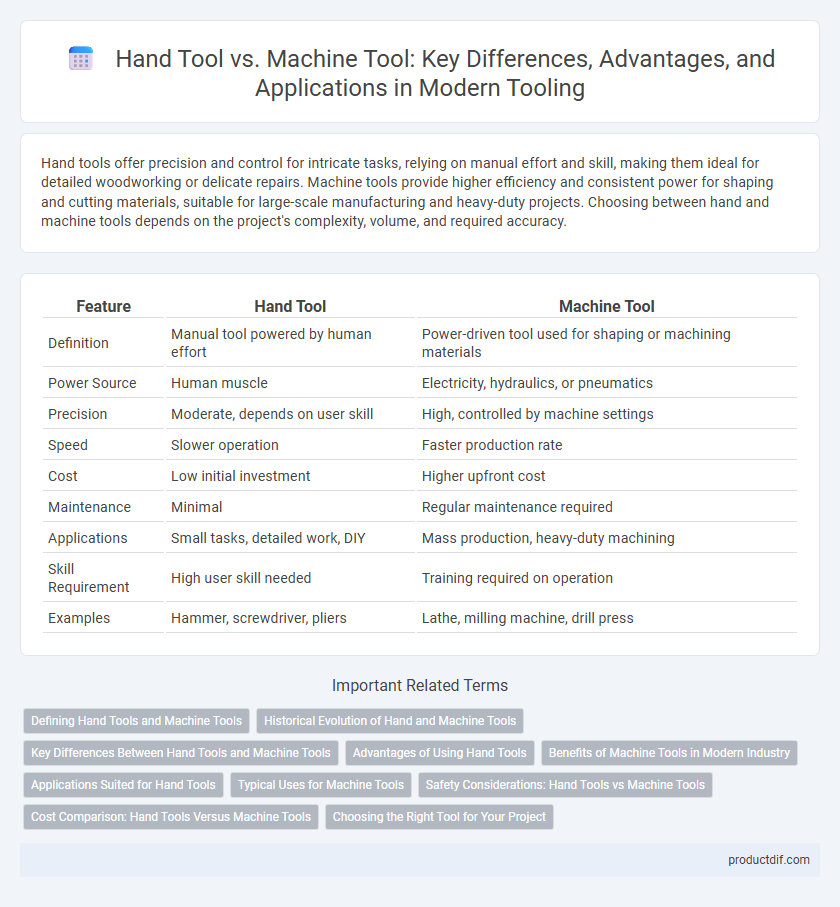

Table of Comparison

| Feature | Hand Tool | Machine Tool |

|---|---|---|

| Definition | Manual tool powered by human effort | Power-driven tool used for shaping or machining materials |

| Power Source | Human muscle | Electricity, hydraulics, or pneumatics |

| Precision | Moderate, depends on user skill | High, controlled by machine settings |

| Speed | Slower operation | Faster production rate |

| Cost | Low initial investment | Higher upfront cost |

| Maintenance | Minimal | Regular maintenance required |

| Applications | Small tasks, detailed work, DIY | Mass production, heavy-duty machining |

| Skill Requirement | High user skill needed | Training required on operation |

| Examples | Hammer, screwdriver, pliers | Lathe, milling machine, drill press |

Defining Hand Tools and Machine Tools

Hand tools are manually operated devices used for shaping, assembling, or repairing materials, relying on human physical effort without the need for electrical power. Machine tools are power-driven devices designed to shape or fabricate metal and other rigid materials through precise, automated processes such as cutting, drilling, or milling. The fundamental distinction lies in hand tools requiring human force while machine tools utilize mechanical or electrical energy for enhanced accuracy and efficiency.

Historical Evolution of Hand and Machine Tools

Hand tools have been essential since prehistoric times, evolving from simple stone implements to metal tools crafted by ancient civilizations like the Egyptians and Romans. The Industrial Revolution marked a pivotal shift with the invention of machine tools such as lathes and milling machines, enabling mass production and precision manufacturing. Continuous advancements in technology have transformed these tools, integrating automation and computer numerical control (CNC) systems for enhanced efficiency and accuracy.

Key Differences Between Hand Tools and Machine Tools

Hand tools require manual operation and are powered by human effort, making them ideal for precision and small-scale tasks, whereas machine tools utilize mechanical power for efficiency and consistency in large-scale manufacturing. Hand tools offer portability and simplicity with tactile feedback, while machine tools provide automated motion and higher production speed through computerized controls. The choice between hand and machine tools depends on factors like task complexity, volume, accuracy requirements, and operator skill level.

Advantages of Using Hand Tools

Hand tools offer greater precision and control for delicate tasks, reducing the risk of damaging materials. They require no electricity, making them highly portable and usable in remote or power-restricted environments. The simplicity of hand tools also leads to lower maintenance costs and longer tool lifespan compared to machine tools.

Benefits of Machine Tools in Modern Industry

Machine tools offer unparalleled precision and repeatability, essential for high-quality manufacturing in modern industry. They significantly increase production speed while reducing labor costs and minimizing human error. Enhanced automation capabilities of machine tools support complex component fabrication, improving efficiency and scalability in industrial processes.

Applications Suited for Hand Tools

Hand tools excel in precision tasks such as woodworking, jewelry making, and electrical work, where delicate manipulation is required. Applications that involve small-scale repairs, detailed craftsmanship, or areas with limited space benefit significantly from the portability and control of hand tools. Tasks like tightening screws, carving, and measuring are ideally suited for hand tools due to their ability to deliver fine control more efficiently than machine tools.

Typical Uses for Machine Tools

Machine tools are primarily used for precision shaping, cutting, and forming of metal and other rigid materials in manufacturing environments. They enable mass production of complex parts with consistent accuracy, such as engine components, automotive parts, and aerospace structures. Typical machine tools include lathes, milling machines, and drill presses, essential for fabrication and assembly processes.

Safety Considerations: Hand Tools vs Machine Tools

Hand tools generally pose lower safety risks due to their manual operation and limited power, but improper use can still cause injuries such as cuts, punctures, or strains. Machine tools, powered by electricity or other energy sources, require stricter safety protocols including guarding, emergency stops, and proper training to prevent severe hazards like entanglement, crushing, or electric shock. Ensuring the use of personal protective equipment (PPE) and regular maintenance reduces accidents in both hand tool and machine tool environments.

Cost Comparison: Hand Tools Versus Machine Tools

Hand tools generally have a lower initial cost compared to machine tools, making them more affordable for small-scale projects and individual use. Machine tools require significant upfront investment but offer higher productivity and precision, leading to cost savings over time in industrial applications. Maintenance and operational expenses for machine tools are higher, but their efficiency and durability can offset these costs in large-scale manufacturing environments.

Choosing the Right Tool for Your Project

Hand tools offer precision and control for detailed tasks, making them ideal for small-scale projects and fine craftsmanship. Machine tools provide power and efficiency, suitable for large-scale operations and repetitive work requiring consistent accuracy. Selecting the right tool depends on project complexity, material type, and production volume to ensure optimal results and resource management.

Hand Tool vs Machine Tool Infographic

productdif.com

productdif.com