Brazing joins metals by melting a filler metal at lower temperatures without melting the base materials, producing clean, strong, and precise joints ideal for thin or delicate components. Welding involves melting both the base metals and filler material, creating a robust bond suitable for heavy-duty applications and structural components. Choosing between brazing and welding depends on factors like metal type, joint strength requirements, and thermal sensitivity.

Table of Comparison

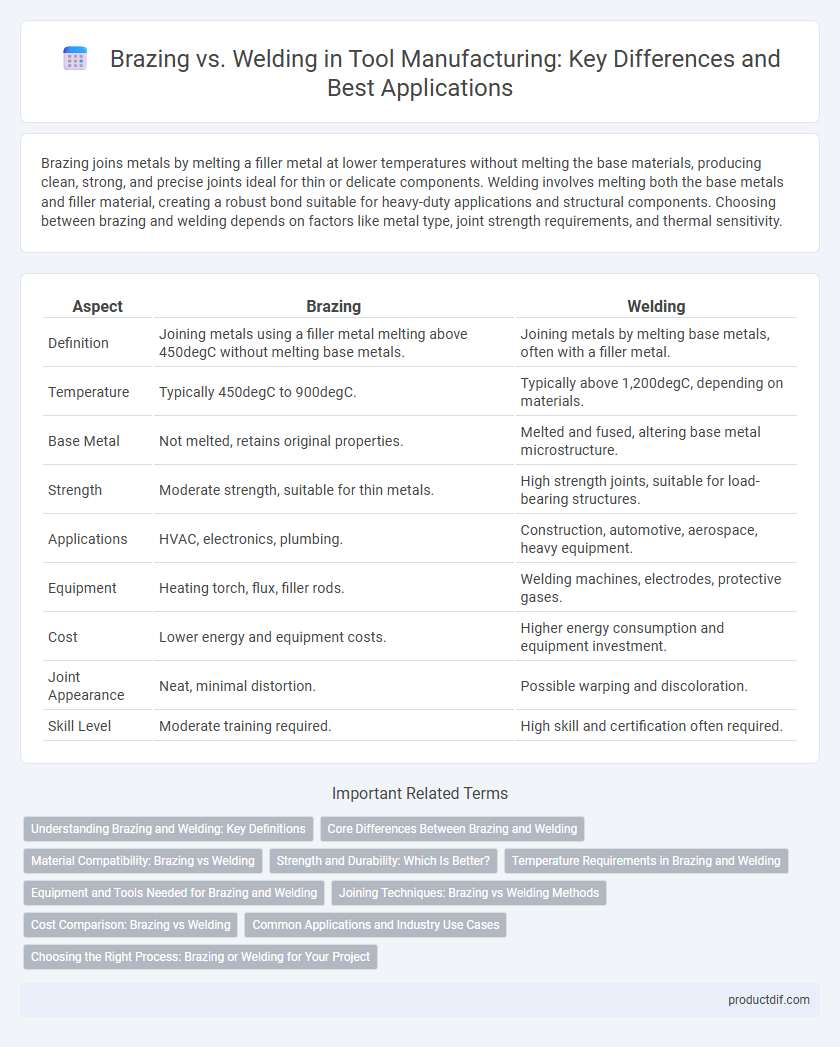

| Aspect | Brazing | Welding |

|---|---|---|

| Definition | Joining metals using a filler metal melting above 450degC without melting base metals. | Joining metals by melting base metals, often with a filler metal. |

| Temperature | Typically 450degC to 900degC. | Typically above 1,200degC, depending on materials. |

| Base Metal | Not melted, retains original properties. | Melted and fused, altering base metal microstructure. |

| Strength | Moderate strength, suitable for thin metals. | High strength joints, suitable for load-bearing structures. |

| Applications | HVAC, electronics, plumbing. | Construction, automotive, aerospace, heavy equipment. |

| Equipment | Heating torch, flux, filler rods. | Welding machines, electrodes, protective gases. |

| Cost | Lower energy and equipment costs. | Higher energy consumption and equipment investment. |

| Joint Appearance | Neat, minimal distortion. | Possible warping and discoloration. |

| Skill Level | Moderate training required. | High skill and certification often required. |

Understanding Brazing and Welding: Key Definitions

Brazing joins metals by melting a filler metal above 450degC without melting the base metals, creating a strong, leak-proof bond ideal for delicate or dissimilar materials. Welding involves melting the base metals themselves, typically above 1,370degC, to fuse them together, resulting in a robust, structural joint suited for high-strength applications. Both processes require heat sources like torches or electrical arcs and are selected based on material compatibility, joint design, and mechanical requirements.

Core Differences Between Brazing and Welding

Brazing and welding both join metals but differ significantly in temperature and process; brazing melts a filler metal below the base metals' melting point, while welding melts the base metals themselves to form a strong joint. Brazing uses capillary action to bond components, suitable for dissimilar metals and thinner materials, whereas welding creates a fused joint ideal for heavy-duty, high-strength applications. Brazed joints maintain the metallurgical properties of the base metals, unlike welded joints, which involve significant thermal alteration and potential distortion.

Material Compatibility: Brazing vs Welding

Brazing joins dissimilar metals such as copper to steel or aluminum to stainless steel by melting a filler metal with a lower melting point than the base materials, preserving the integrity of heat-sensitive components. Welding requires similar or compatible metals because it melts the base materials together, which can cause distortion or weakening in dissimilar metal joints. This makes brazing particularly advantageous for complex assemblies where varied metal compatibility and thermal management are critical.

Strength and Durability: Which Is Better?

Brazing creates strong, durable joints by melting a filler metal below the base metals' melting points, maintaining the integrity of heat-sensitive materials and reducing distortion. Welding fuses base metals directly, resulting in higher strength joints ideal for heavy-duty applications but with increased risk of warping and residual stress. For maximum durability, welding typically provides superior structural strength, while brazing offers better performance for delicate or heat-sensitive assemblies.

Temperature Requirements in Brazing and Welding

Brazing typically requires temperatures ranging from 450degC to 900degC, which are lower than the melting points of the base metals, allowing for joint formation without melting the workpieces. Welding involves much higher temperatures, often exceeding 1,300degC, sufficient to melt the base metals and create a fused joint upon cooling. These temperature differences directly affect the thermal distortion, strength, and application suitability of brazed versus welded joints.

Equipment and Tools Needed for Brazing and Welding

Brazing requires specialized equipment such as a torch with a precise flame, flux, and filler metals that melt at lower temperatures, often using propane or acetylene gases. Welding demands more robust tools including welding machines (MIG, TIG, or stick welders), protective gear like helmets and gloves, and consumables like electrodes or welding wire designed to fuse metals at high temperatures. Both processes rely on specific safety equipment, but welding involves more complex machinery and power sources, whereas brazing utilizes simpler, portable tools for metal joining.

Joining Techniques: Brazing vs Welding Methods

Brazing and welding are essential joining techniques used in metal fabrication, each with distinct heat application and material interaction processes. Brazing joins metals by melting a filler metal below the base metals' melting points, ensuring minimal impact on the parent materials and ideal for dissimilar metals. Welding fuses base metals by raising their temperature to melting, creating a strong, continuous joint suited for structural applications requiring high strength and durability.

Cost Comparison: Brazing vs Welding

Brazing generally incurs lower costs than welding due to its reduced energy consumption and simpler equipment requirements. Welding often demands higher expenses for skilled labor, specialized machinery, and safety measures, which increase overall project budgets. Selecting brazing can optimize cost-efficiency without compromising joint strength in suitable metal-joining applications.

Common Applications and Industry Use Cases

Brazing is commonly used in HVAC systems, electronics, and automotive industries for joining dissimilar metals without melting the base materials, providing strong, leak-proof joints ideal for thin components. Welding dominates construction, shipbuilding, and heavy machinery manufacturing due to its ability to create robust, high-strength joints between similar metals, suitable for load-bearing structures. Both processes serve critical roles in aerospace and pipeline industries, where reliability and precision in metal joining ensure safety and performance.

Choosing the Right Process: Brazing or Welding for Your Project

Choosing the right process between brazing and welding depends on the materials involved, joint strength requirements, and heat sensitivity. Brazing uses a filler metal with a lower melting point than the base metals, minimizing thermal distortion and making it ideal for thin or heat-sensitive materials. Welding creates a stronger, more permanent bond by melting the base metals, suitable for heavy-duty applications requiring high structural integrity.

Brazing vs Welding Infographic

productdif.com

productdif.com