Forged wrenches offer superior strength and durability due to their manufacturing process, where metal is heated and shaped under high pressure, ensuring a dense and resilient structure. Stamped wrenches are made by cutting and shaping a metal sheet, resulting in a lighter and less expensive tool but with reduced toughness and a higher risk of bending or breaking under heavy use. Choosing a forged wrench is ideal for professional or heavy-duty tasks, while stamped wrenches suit light, occasional applications where budget and weight are priorities.

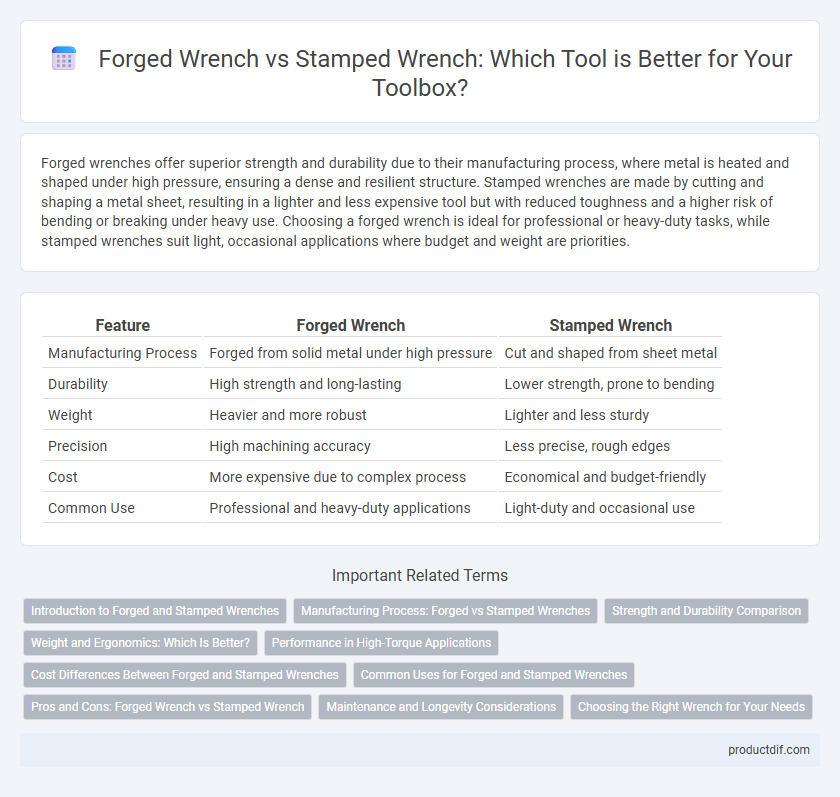

Table of Comparison

| Feature | Forged Wrench | Stamped Wrench |

|---|---|---|

| Manufacturing Process | Forged from solid metal under high pressure | Cut and shaped from sheet metal |

| Durability | High strength and long-lasting | Lower strength, prone to bending |

| Weight | Heavier and more robust | Lighter and less sturdy |

| Precision | High machining accuracy | Less precise, rough edges |

| Cost | More expensive due to complex process | Economical and budget-friendly |

| Common Use | Professional and heavy-duty applications | Light-duty and occasional use |

Introduction to Forged and Stamped Wrenches

Forged wrenches are crafted by heating metal and shaping it under high pressure, resulting in superior strength and durability ideal for heavy-duty applications. Stamped wrenches, made by cutting and pressing metal sheets into shape, offer a lighter, more cost-effective option often used for light to moderate tasks. Understanding the manufacturing differences helps users select the appropriate wrench based on performance requirements and budget constraints.

Manufacturing Process: Forged vs Stamped Wrenches

Forged wrenches are produced by heating metal and shaping it under high pressure, which enhances durability and strength through a dense grain structure. Stamped wrenches are made by cutting and pressing metal sheets in a single step, resulting in lighter tools but with lower mechanical toughness. The manufacturing process significantly influences the wrench's performance, with forging providing superior resistance to wear and deformation compared to stamping.

Strength and Durability Comparison

Forged wrenches exhibit superior strength and durability due to their manufacturing process, which involves shaping metal under high pressure to create a denser and more resilient structure. Stamped wrenches, made by pressing sheet metal into shape, often possess thinner walls and are more prone to bending or breaking under heavy torque. Professionals prefer forged wrenches for demanding tasks requiring long-lasting performance and resistance to wear.

Weight and Ergonomics: Which Is Better?

Forged wrenches typically offer superior durability and a balanced weight that enhances ergonomics, reducing user fatigue during extended use. Stamped wrenches are lighter due to their thinner construction but may sacrifice comfort and control, leading to less efficient handling. For tasks requiring precision and prolonged effort, forged wrenches generally provide a better ergonomic experience with optimal weight distribution.

Performance in High-Torque Applications

Forged wrenches offer superior strength and durability in high-torque applications due to their solid, grain-aligned structure, allowing them to withstand greater stress without bending or breaking. Stamped wrenches, made from thinner, cut metal sheets, typically lack the robustness required for intense torque, leading to potential deformation under heavy loads. Professionals favor forged wrenches for tasks involving heavy machinery or automotive repairs where reliability and performance under pressure are critical.

Cost Differences Between Forged and Stamped Wrenches

Forged wrenches typically cost more than stamped wrenches due to their manufacturing process, which involves shaping metal under high pressure to enhance strength and durability. Stamped wrenches are produced by cutting and pressing sheet metal, resulting in lower production costs but reduced toughness and lifespan. The price difference reflects the trade-off between the higher upfront investment in forged wrenches and the budget-friendly option of stamped wrenches, which may require more frequent replacement.

Common Uses for Forged and Stamped Wrenches

Forged wrenches are commonly used in heavy-duty applications such as automotive repair, industrial machinery maintenance, and construction due to their superior strength and durability. Stamped wrenches are ideal for light to medium tasks including household repairs, bicycle maintenance, and assembling furniture, where precision and cost-effectiveness are important. Both types serve essential roles in toolkits, with forged wrenches favored for high-torque environments and stamped wrenches preferred for portability and affordability.

Pros and Cons: Forged Wrench vs Stamped Wrench

Forged wrenches offer superior strength, durability, and resistance to wear due to their manufacturing process, making them ideal for heavy-duty applications; however, they tend to be heavier and more expensive. Stamped wrenches are lighter and more cost-effective, suitable for light to moderate tasks, but they lack the robustness and longevity of forged counterparts. Choosing between forged and stamped wrenches depends on the balance between budget, weight preference, and the intensity of the required use.

Maintenance and Longevity Considerations

Forged wrenches exhibit superior maintenance benefits due to their enhanced durability and resistance to wear, reducing the frequency of replacements. Stamped wrenches, while lighter and cheaper, tend to suffer from metal fatigue and deformation, necessitating more frequent inspections and careful handling. Investing in forged wrenches ensures longer tool lifespan and less downtime, optimizing overall tool maintenance costs.

Choosing the Right Wrench for Your Needs

Forged wrenches offer superior strength and durability due to their solid metal construction, making them ideal for heavy-duty tasks and frequent use. Stamped wrenches, produced by pressing metal sheets into shape, are lighter and more cost-effective but less robust, suited for light or occasional work. Selecting the right wrench depends on balancing the need for longevity, torque capacity, and budget considerations to ensure optimal performance for specific applications.

Forged Wrench vs Stamped Wrench Infographic

productdif.com

productdif.com