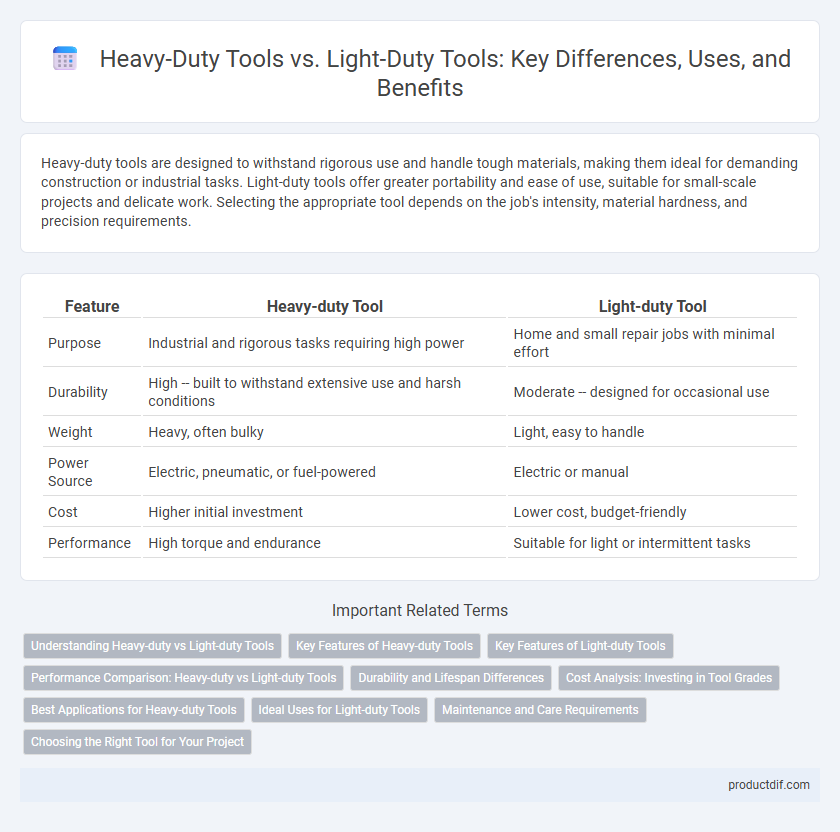

Heavy-duty tools are designed to withstand rigorous use and handle tough materials, making them ideal for demanding construction or industrial tasks. Light-duty tools offer greater portability and ease of use, suitable for small-scale projects and delicate work. Selecting the appropriate tool depends on the job's intensity, material hardness, and precision requirements.

Table of Comparison

| Feature | Heavy-duty Tool | Light-duty Tool |

|---|---|---|

| Purpose | Industrial and rigorous tasks requiring high power | Home and small repair jobs with minimal effort |

| Durability | High -- built to withstand extensive use and harsh conditions | Moderate -- designed for occasional use |

| Weight | Heavy, often bulky | Light, easy to handle |

| Power Source | Electric, pneumatic, or fuel-powered | Electric or manual |

| Cost | Higher initial investment | Lower cost, budget-friendly |

| Performance | High torque and endurance | Suitable for light or intermittent tasks |

Understanding Heavy-duty vs Light-duty Tools

Heavy-duty tools are designed for intensive tasks requiring durability and high performance, commonly used in construction, manufacturing, and industrial settings. Light-duty tools cater to simpler, everyday projects like household repairs and crafting where precision and ease of use are prioritized. Selecting the appropriate tool depends on the task's demand for strength, longevity, and operational intensity.

Key Features of Heavy-duty Tools

Heavy-duty tools are designed with reinforced materials and robust construction to withstand intense usage and high-stress environments. They feature powerful motors, durable components, and enhanced ergonomics to ensure sustained performance in demanding industrial applications. These tools often include advanced safety mechanisms and greater torque capacity compared to light-duty tools, making them ideal for professional-grade tasks.

Key Features of Light-duty Tools

Light-duty tools are designed for precision and ease of use in small-scale tasks, typically featuring lightweight materials and ergonomic grips to reduce user fatigue. They often incorporate compact sizes and lower power outputs, making them ideal for household repairs and delicate operations. These tools prioritize portability and affordability while ensuring adequate performance for non-intensive applications.

Performance Comparison: Heavy-duty vs Light-duty Tools

Heavy-duty tools deliver superior performance with higher torque, durability, and power, making them ideal for industrial and construction tasks requiring continuous use and heavy loads. Light-duty tools excel in precision, portability, and ease of use, suitable for smaller projects, DIY tasks, and delicate materials. Choosing between heavy-duty and light-duty tools depends on the specific demands of the job, with heavy-duty tools offering enhanced efficiency for rigorous applications.

Durability and Lifespan Differences

Heavy-duty tools are engineered with robust materials such as high-grade steel and reinforced components, resulting in superior durability and an extended lifespan under strenuous conditions. Light-duty tools, constructed from lighter materials like aluminum or plastic, offer less resistance to wear and tear, making them ideal for occasional or low-intensity tasks but limiting their overall longevity. The significant difference in material strength and build quality directly impacts the lifespan, with heavy-duty tools often lasting several times longer than light-duty counterparts in demanding environments.

Cost Analysis: Investing in Tool Grades

Investing in heavy-duty tools typically involves higher upfront costs but offers greater durability and longer lifespan compared to light-duty tools, reducing replacement frequency and maintenance expenses. Light-duty tools have lower initial purchase prices suitable for occasional use but may incur higher long-term costs due to increased wear and potential failure under stress. A cost analysis must consider the balance between purchase price, tool performance, and expected usage intensity to optimize investment in tool grades.

Best Applications for Heavy-duty Tools

Heavy-duty tools are best suited for applications requiring high power and durability, such as construction, metalworking, and demolition projects. These tools handle tough materials like concrete, steel, and hardwoods with precision and efficiency, ensuring reliability in demanding environments. Their robust design and enhanced torque make them ideal for professional use in industrial and heavy fabrication settings.

Ideal Uses for Light-duty Tools

Light-duty tools are ideal for tasks that require precision and minimal force, such as assembling electronics, crafting, or light home repairs like tightening screws or small paint jobs. These tools offer greater control, reduced user fatigue, and enhanced maneuverability, making them perfect for detailed work on delicate materials. Their lightweight design allows for easy handling in confined spaces, where heavy-duty tools would be cumbersome or cause damage.

Maintenance and Care Requirements

Heavy-duty tools require more frequent inspections, lubrication, and parts replacement due to intensive use and exposure to harsh conditions, ensuring optimal performance and longevity. Light-duty tools necessitate less rigorous maintenance, often limited to occasional cleaning and basic upkeep, suitable for infrequent or light tasks. Proper adherence to specific care protocols for each tool type minimizes downtime and enhances safety during operation.

Choosing the Right Tool for Your Project

Heavy-duty tools are designed for demanding tasks requiring high power, durability, and extended use, making them ideal for construction, demolition, or industrial projects. Light-duty tools offer precision and ease of use for smaller, detail-oriented tasks such as home repairs or crafting, providing greater control and comfort. Selecting the right tool depends on the project's scale, material hardness, and required performance to ensure efficiency and safety.

Heavy-duty Tool vs Light-duty Tool Infographic

productdif.com

productdif.com