Soft tooling offers a cost-effective and flexible solution for low-volume manufacturing and prototyping, utilizing materials like aluminum or silicone that allow rapid iteration and design changes. Hard tooling, made from durable materials such as steel, provides higher precision and longevity ideal for high-volume production runs, ensuring consistent quality and reduced wear over time. Selecting between soft and hard tooling depends on factors like production volume, budget, and the complexity of the part design.

Table of Comparison

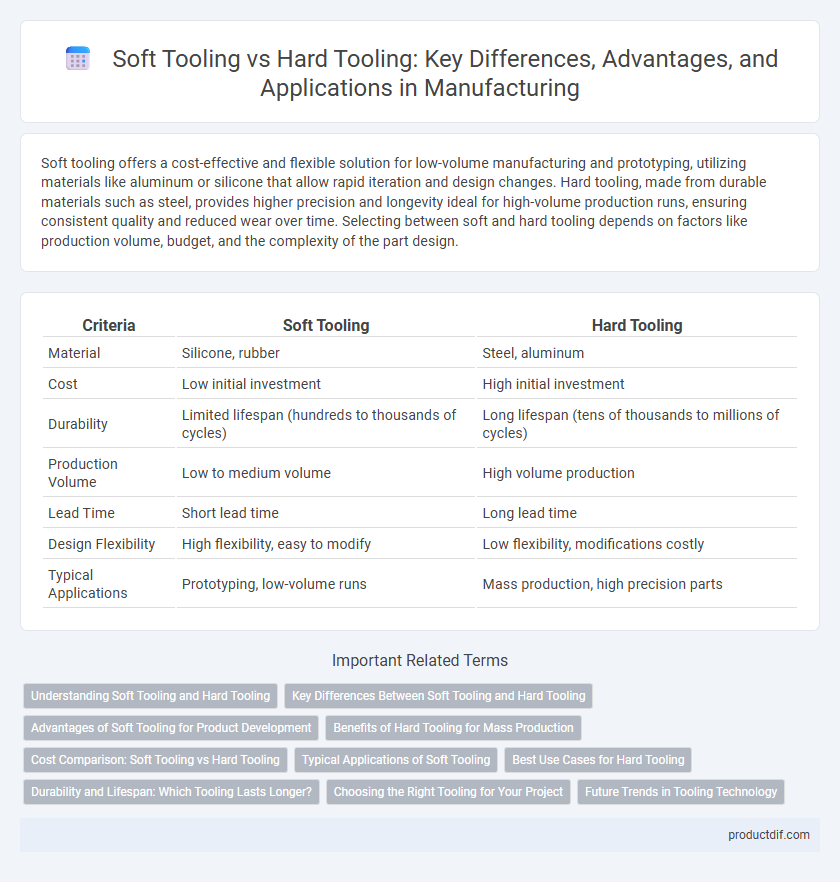

| Criteria | Soft Tooling | Hard Tooling |

|---|---|---|

| Material | Silicone, rubber | Steel, aluminum |

| Cost | Low initial investment | High initial investment |

| Durability | Limited lifespan (hundreds to thousands of cycles) | Long lifespan (tens of thousands to millions of cycles) |

| Production Volume | Low to medium volume | High volume production |

| Lead Time | Short lead time | Long lead time |

| Design Flexibility | High flexibility, easy to modify | Low flexibility, modifications costly |

| Typical Applications | Prototyping, low-volume runs | Mass production, high precision parts |

Understanding Soft Tooling and Hard Tooling

Soft tooling involves the use of less durable materials such as aluminum or epoxy for creating molds, enabling faster and more cost-effective prototyping and small production runs. Hard tooling, made from durable materials like steel, is designed for high-volume manufacturing, offering greater precision and longevity but requiring a higher initial investment and longer lead times. Understanding the differences between soft tooling and hard tooling is crucial for selecting the appropriate method based on production scale, budget, and project timelines.

Key Differences Between Soft Tooling and Hard Tooling

Soft tooling utilizes materials like aluminum or silicone, enabling faster and cost-effective prototyping with shorter lead times, while hard tooling employs durable materials such as steel designed for high-volume production with enhanced longevity. Soft tooling offers greater flexibility for design modifications and lower initial investment, contrasting with hard tooling's higher upfront cost but superior precision and durability. The choice between soft and hard tooling depends on production volume, budget constraints, and the need for design iterations in manufacturing processes.

Advantages of Soft Tooling for Product Development

Soft tooling offers significant cost efficiency and faster production cycles compared to hard tooling, making it ideal for rapid prototyping and early-stage product development. Its flexibility allows easy modifications, enabling designers to iterate designs quickly and respond to market feedback without extensive delays. This adaptability reduces initial investment risks and accelerates time-to-market for innovative products.

Benefits of Hard Tooling for Mass Production

Hard tooling offers superior durability and precision, making it ideal for mass production environments where consistency and high volume output are critical. Its ability to withstand repeated use with minimal wear reduces downtime and maintenance costs, enhancing overall manufacturing efficiency. The investment in hard tooling often leads to lower per-unit costs over large production runs due to its long lifespan and high-quality output.

Cost Comparison: Soft Tooling vs Hard Tooling

Soft tooling typically incurs lower upfront costs due to the use of less durable materials like silicone or polyurethane, making it ideal for prototyping and low-volume production. Hard tooling demands a higher initial investment because of materials like steel and aluminum, but offers greater durability and is cost-effective for large-scale manufacturing. The choice between soft and hard tooling hinges on balancing budget constraints with production volume and longevity requirements.

Typical Applications of Soft Tooling

Soft tooling is primarily used in prototyping and low-volume production runs due to its cost-effectiveness and faster manufacturing process. Typical applications include producing plastic parts for automotive interiors, consumer electronics, and medical devices where design revisions are frequent. This tooling method allows engineers to test and refine designs before investing in more durable hard tooling for mass production.

Best Use Cases for Hard Tooling

Hard tooling is best suited for mass production processes requiring high precision, durability, and repeatability, such as injection molding for plastic parts and metal stamping in automotive manufacturing. Its robust construction withstands high-pressure operations and extended usage cycles, making it ideal for producing consistent, complex components at scale. Industries demanding tight tolerances and long production runs benefit from hard tooling's superior strength and longevity compared to soft tooling alternatives.

Durability and Lifespan: Which Tooling Lasts Longer?

Hard tooling typically offers superior durability and a longer lifespan compared to soft tooling due to its construction from high-strength materials such as steel or aluminum alloys. Soft tooling, often made from silicone or urethane, is prone to wear and deformation under high-pressure or long production runs, making it ideal for prototyping or short-term use. The choice between soft and hard tooling depends on production volume and cost considerations, but hard tooling is preferred when longevity and consistent quality over time are critical.

Choosing the Right Tooling for Your Project

Selecting the right tooling between soft tooling and hard tooling depends on project volume, budget, and timeline requirements. Soft tooling, made from materials like aluminum or epoxy, offers faster production and lower upfront costs suited for prototyping or small to medium runs, while hard tooling, typically steel, provides durability and precision for high-volume manufacturing. Understanding the trade-offs in cost, lead time, and part accuracy ensures optimal tooling choice that aligns with production goals and lifecycle demands.

Future Trends in Tooling Technology

Future trends in tooling technology highlight a growing shift towards soft tooling due to its adaptability, cost-efficiency, and rapid prototyping capabilities, especially in industries like automotive and aerospace. Advances in additive manufacturing and materials science enhance soft tooling's durability and precision, narrowing the performance gap with traditional hard tooling. Integration of digital twins and AI-driven design optimization further propels the evolution of tooling, enabling smarter, faster, and more flexible production workflows.

Soft Tooling vs Hard Tooling Infographic

productdif.com

productdif.com