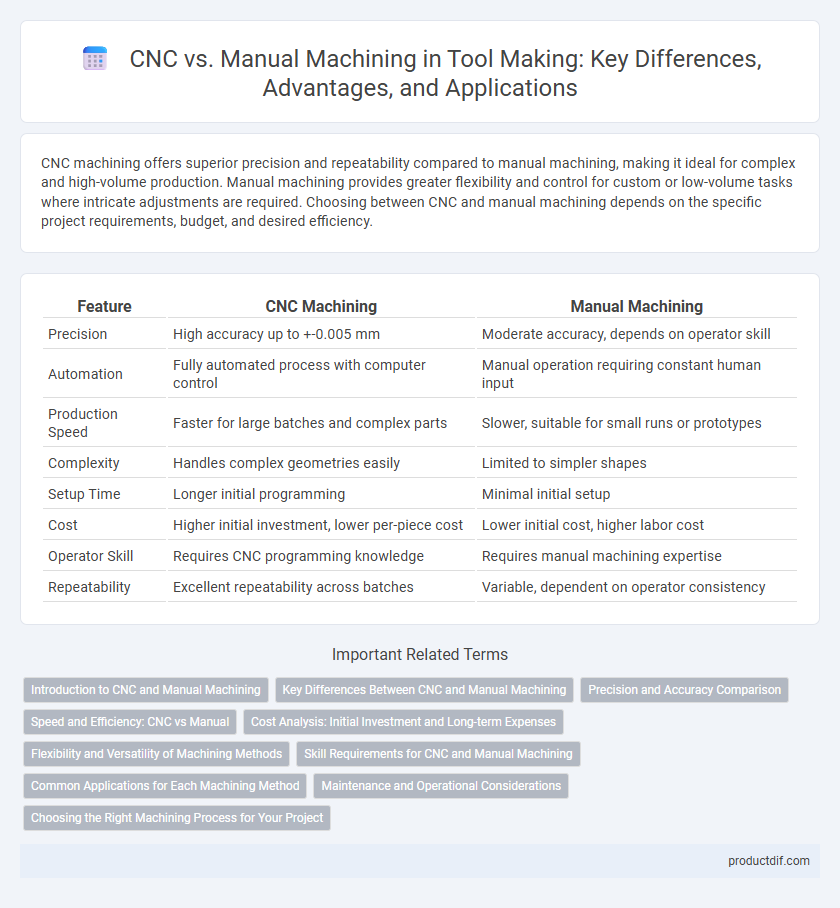

CNC machining offers superior precision and repeatability compared to manual machining, making it ideal for complex and high-volume production. Manual machining provides greater flexibility and control for custom or low-volume tasks where intricate adjustments are required. Choosing between CNC and manual machining depends on the specific project requirements, budget, and desired efficiency.

Table of Comparison

| Feature | CNC Machining | Manual Machining |

|---|---|---|

| Precision | High accuracy up to +-0.005 mm | Moderate accuracy, depends on operator skill |

| Automation | Fully automated process with computer control | Manual operation requiring constant human input |

| Production Speed | Faster for large batches and complex parts | Slower, suitable for small runs or prototypes |

| Complexity | Handles complex geometries easily | Limited to simpler shapes |

| Setup Time | Longer initial programming | Minimal initial setup |

| Cost | Higher initial investment, lower per-piece cost | Lower initial cost, higher labor cost |

| Operator Skill | Requires CNC programming knowledge | Requires manual machining expertise |

| Repeatability | Excellent repeatability across batches | Variable, dependent on operator consistency |

Introduction to CNC and Manual Machining

CNC machining uses computer numerical control to automate the cutting and shaping of materials with high precision, enabling complex designs and repeatability. Manual machining relies on skilled operators to control tools like lathes or mills directly, offering flexibility for custom or small-scale production. CNC technology increases efficiency and accuracy, while manual machining provides hands-on adjustments and is often preferred for prototype development or intricate tasks.

Key Differences Between CNC and Manual Machining

CNC machining offers automated precision with computer-controlled tools, enabling complex shapes and consistent quality, while manual machining relies on skilled operators for direct tool manipulation, resulting in greater variability. CNC machines provide faster production speeds and higher repeatability, reducing human error and increasing efficiency. Manual machining excels in custom, low-volume jobs where flexibility and hands-on adjustments are needed, contrasting with CNC's suitability for mass production and intricate designs.

Precision and Accuracy Comparison

CNC machining consistently delivers higher precision and accuracy compared to manual machining, achieving tolerances as tight as +-0.005 mm due to computerized control and automation. Manual machining relies heavily on operator skill, typically resulting in wider tolerances around +-0.05 mm, which can lead to variability in part quality. CNC machines excel in repeatability, producing uniform components essential for industries such as aerospace and medical devices where exact measurements are critical.

Speed and Efficiency: CNC vs Manual

CNC machining delivers superior speed and efficiency by automating complex tasks with precise, repeatable movements, significantly reducing production time compared to manual machining. Manual machining relies on operator skill and physical adjustments, which increases cycle times and potential for human error. In high-volume manufacturing, CNC systems outperform manual methods by maintaining consistent output and minimizing downtime.

Cost Analysis: Initial Investment and Long-term Expenses

CNC machining involves a higher initial investment due to the cost of computerized equipment and software, while manual machining requires a lower upfront purchase for traditional tools and machinery. Long-term expenses for CNC include maintenance, software updates, and skilled operator training, whereas manual machining incurs ongoing costs in labor intensity and slower production rates. Evaluating total cost of ownership reveals CNC machining's efficiency benefits can offset its higher initial expense through increased precision and reduced waste over time.

Flexibility and Versatility of Machining Methods

CNC machining offers superior flexibility by allowing programmable precision across complex geometries and rapid adjustments to design changes. Manual machining provides versatility for simple, low-volume tasks where operator skill directly influences customization. CNC machines excel in repeatability and intricate detail, while manual methods remain valuable for prototyping and custom one-off components.

Skill Requirements for CNC and Manual Machining

CNC machining requires proficiency in computer programming, CAD/CAM software, and machine operation, emphasizing precision and automation skills. Manual machining demands strong hands-on expertise, manual dexterity, and an in-depth understanding of machine tools, measuring instruments, and material properties. Both skill sets influence productivity and quality, with CNC favoring technical knowledge and manual machining relying on craftsmanship.

Common Applications for Each Machining Method

CNC machining is widely used in aerospace, automotive, and medical industries for producing complex, high-precision parts with consistent quality and fast production rates. Manual machining remains preferred for low-volume production, prototyping, and custom repairs where flexibility and hands-on adjustments are essential. Metalworking, mold making, and woodworking benefit from both methods depending on the project's scale and precision requirements.

Maintenance and Operational Considerations

CNC machines require regular software updates, calibrated sensors, and specialized technicians to maintain optimal performance, whereas manual machining primarily relies on mechanical upkeep such as lubrication and alignment checks. Operationally, CNC machining offers higher precision and automation, reducing manual labor and operator fatigue, while manual machining demands skilled craftsmen for detailed adjustments and troubleshooting. Maintenance costs for CNC systems are typically higher due to complex electronics, but the increased efficiency and reduced error rates can offset these expenses over time.

Choosing the Right Machining Process for Your Project

Selecting the appropriate machining process depends on project complexity, precision requirements, and production volume. CNC machining offers high accuracy and repeatability for intricate designs, making it ideal for large-scale manufacturing and complex components. Manual machining suits simpler, low-volume projects where flexibility and cost-effectiveness are priorities.

CNC vs Manual Machining Infographic

productdif.com

productdif.com