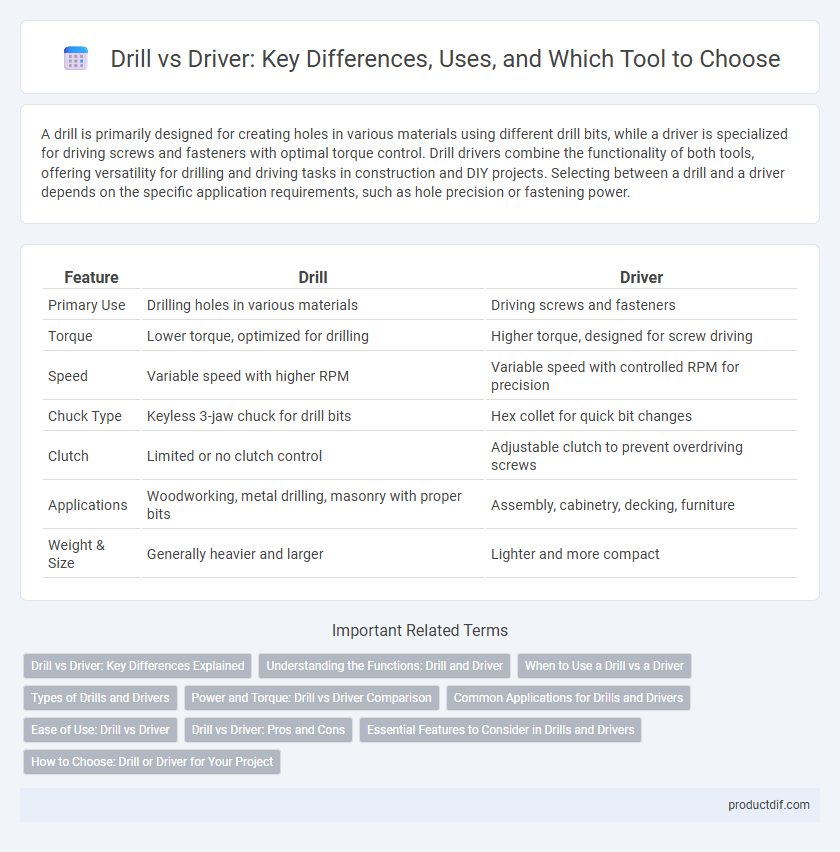

A drill is primarily designed for creating holes in various materials using different drill bits, while a driver is specialized for driving screws and fasteners with optimal torque control. Drill drivers combine the functionality of both tools, offering versatility for drilling and driving tasks in construction and DIY projects. Selecting between a drill and a driver depends on the specific application requirements, such as hole precision or fastening power.

Table of Comparison

| Feature | Drill | Driver |

|---|---|---|

| Primary Use | Drilling holes in various materials | Driving screws and fasteners |

| Torque | Lower torque, optimized for drilling | Higher torque, designed for screw driving |

| Speed | Variable speed with higher RPM | Variable speed with controlled RPM for precision |

| Chuck Type | Keyless 3-jaw chuck for drill bits | Hex collet for quick bit changes |

| Clutch | Limited or no clutch control | Adjustable clutch to prevent overdriving screws |

| Applications | Woodworking, metal drilling, masonry with proper bits | Assembly, cabinetry, decking, furniture |

| Weight & Size | Generally heavier and larger | Lighter and more compact |

Drill vs Driver: Key Differences Explained

A drill primarily creates holes using a rotating drill bit, while a driver is designed to drive screws and fasteners with precise torque control. Drills offer adjustable speeds and hammering functions for versatile applications, whereas drivers focus on quick fastening with features like clutch settings to prevent over-tightening. Understanding these distinctions ensures selecting the right tool for construction, woodworking, or home improvement tasks.

Understanding the Functions: Drill and Driver

A drill is primarily designed for creating holes by rotating drill bits at high speeds, ideal for tasks like woodworking, metalworking, and masonry. A driver, on the other hand, focuses on fastening by delivering high torque to drive screws or bolts efficiently, preventing strip-out and ensuring secure connections. Understanding these functions helps in selecting the right tool for precision drilling or fastening in construction and DIY projects.

When to Use a Drill vs a Driver

Use a drill primarily for creating holes in wood, metal, or plastic, utilizing precise speed and torque settings for clean perforations. Choose a driver when fastening screws or bolts, benefiting from its controlled torque to prevent stripping or overdriving fasteners. Understanding the specific tasks of drilling versus driving ensures proper tool selection for efficient construction or assembly projects.

Types of Drills and Drivers

Corded drills provide consistent power for heavy-duty tasks, while cordless drills offer portability and ease of use for light to medium projects. Impact drivers generate high torque via rotational impacts, ideal for driving screws and bolts, whereas drill drivers combine drilling and driving functions with adjustable speed settings for versatile applications. Hammer drills feature a hammering action to drill into concrete and masonry, making them essential for construction and renovation work.

Power and Torque: Drill vs Driver Comparison

Drills typically offer higher rotational speed with moderate torque, ideal for drilling holes in wood, metal, and plastic, whereas drivers provide greater torque at lower speeds, optimizing screw driving and fastening tasks. Power sources vary, with cordless drills using brushless motors delivering consistent power and drivers often featuring adjustable torque settings to prevent stripping screws. Understanding the torque-to-speed ratio is essential for selecting the right tool to maximize efficiency and precision in specific applications.

Common Applications for Drills and Drivers

Drills are primarily used for creating precise holes in various materials like wood, metal, and plastic, making them essential for construction, woodworking, and home improvement projects. Drivers excel at fastening screws and bolts, ensuring secure assembly in cabinetry, furniture building, and equipment maintenance. Selecting the right tool enhances efficiency and accuracy in both drilling and fastening tasks.

Ease of Use: Drill vs Driver

A driver is typically easier to use for fastening screws due to its ergonomic design and adjustable torque settings that prevent stripping. Drills offer more power and versatility but can be bulkier and harder to control for precision tasks. Users seeking straightforward screwdriving often prefer drivers for their lightweight, user-friendly operation.

Drill vs Driver: Pros and Cons

Drills excel at making precise holes in various materials, offering high-speed rotation and adjustable torque for versatile drilling tasks, but they may lack the power needed for heavy fastening. Drivers provide superior torque control and are designed primarily for driving screws and fasteners efficiently, reducing cam-out and stripping, though they can struggle with tasks requiring exact hole drilling. Choosing between a drill and a driver depends on the specific job requirements, balancing drilling precision against fastening power and control.

Essential Features to Consider in Drills and Drivers

Essential features to consider in drills and drivers include torque, speed settings, and battery life, as these directly impact performance and efficiency in various tasks. Drills typically prioritize higher torque and adjustable speed for precise hole drilling, while drivers focus on high rotational speed and impact force for driving screws. Ergonomic design and chuck size also play crucial roles, ensuring comfort during extended use and compatibility with different bit types.

How to Choose: Drill or Driver for Your Project

Choosing between a drill and a driver depends on the specific project requirements; drills offer versatility for drilling holes and light fastening, while drivers provide optimized torque for driving screws efficiently. For heavy-duty fastening tasks or frequent screwdriving, a driver with adjustable clutch settings ensures precision without damaging materials. Assess the type of materials, hole sizes, and fastening needs to select the most effective tool for optimal performance.

Drill vs Driver Infographic

productdif.com

productdif.com