Automated soldering delivers consistent precision and faster production rates compared to hand soldering, significantly reducing human error and rework. It integrates advanced robotics and temperature control to ensure uniform solder joints on complex circuit boards. Hand soldering remains valuable for small-scale projects and repairs, offering flexibility and fine control in delicate or detailed tasks.

Table of Comparison

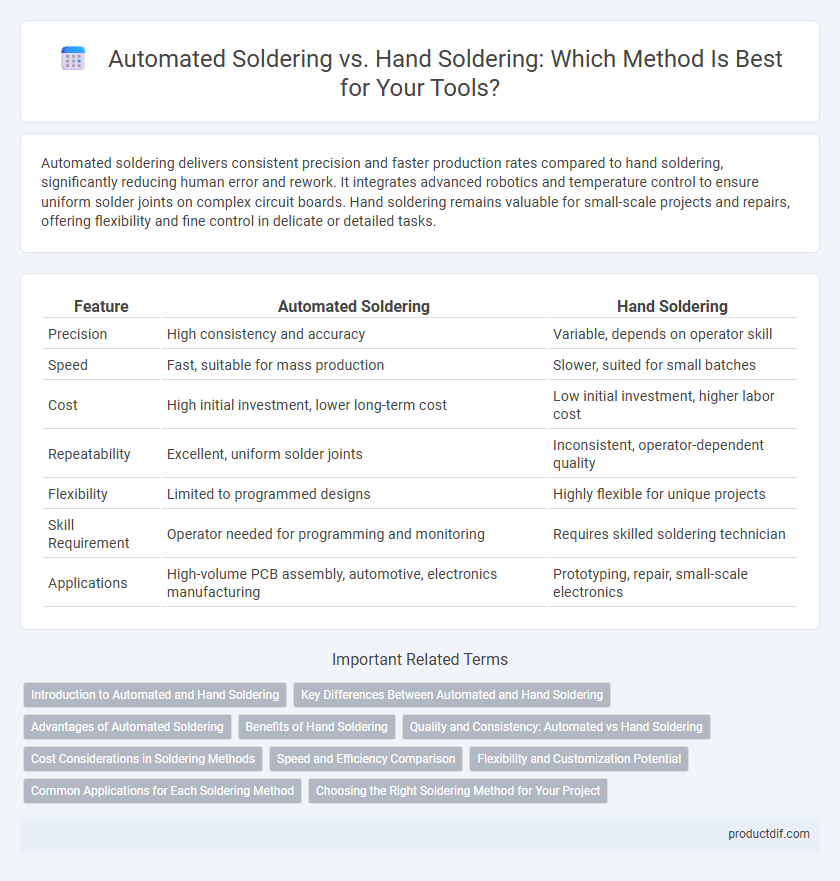

| Feature | Automated Soldering | Hand Soldering |

|---|---|---|

| Precision | High consistency and accuracy | Variable, depends on operator skill |

| Speed | Fast, suitable for mass production | Slower, suited for small batches |

| Cost | High initial investment, lower long-term cost | Low initial investment, higher labor cost |

| Repeatability | Excellent, uniform solder joints | Inconsistent, operator-dependent quality |

| Flexibility | Limited to programmed designs | Highly flexible for unique projects |

| Skill Requirement | Operator needed for programming and monitoring | Requires skilled soldering technician |

| Applications | High-volume PCB assembly, automotive, electronics manufacturing | Prototyping, repair, small-scale electronics |

Introduction to Automated and Hand Soldering

Automated soldering uses robotic arms or machines to apply consistent heat and solder precisely, improving production speed and reducing human error. Hand soldering relies on skilled technicians manually controlling the soldering iron to join components, offering flexibility for complex or small-scale projects. Both methods play essential roles in electronics manufacturing, with automated soldering suited for high-volume outputs and hand soldering preferred for prototyping or repairs.

Key Differences Between Automated and Hand Soldering

Automated soldering delivers consistent temperature control and precise solder placement, significantly reducing human error and increasing production efficiency in electronics manufacturing. In contrast, hand soldering offers greater flexibility and adaptability for complex or delicate assemblies but relies heavily on technician skill and can introduce variability. Key differences include throughput speed, repeatability, and scalability, with automation excelling in high-volume production while hand soldering remains essential for prototyping and repairs.

Advantages of Automated Soldering

Automated soldering enhances precision and consistency by using programmed machines that deliver uniform heat and solder application, reducing defects and improving overall product quality. It significantly increases production speed and efficiency, making it ideal for high-volume manufacturing environments. Automated soldering also minimizes human error and exposure to hazardous fumes, promoting safer workplace conditions.

Benefits of Hand Soldering

Hand soldering offers superior precision and control, allowing technicians to work on intricate components and delicate circuits that automated soldering machines may not handle effectively. It provides greater flexibility for on-the-spot adjustments and repairs, making it ideal for prototyping, customization, and small batch production. Skilled operators can ensure higher-quality joints and reduce the risk of thermal damage by carefully managing heat application during the soldering process.

Quality and Consistency: Automated vs Hand Soldering

Automated soldering ensures superior quality and consistency by precisely controlling temperature, solder volume, and timing, minimizing human error and defects. Hand soldering, while flexible for small batches or complex joints, often results in variable solder quality due to operator skill and fatigue. Consistent joint strength and reduced rework costs are significant benefits of automated soldering in high-volume production environments.

Cost Considerations in Soldering Methods

Automated soldering significantly reduces labor costs by increasing throughput and minimizing human error compared to hand soldering, which requires skilled technicians and longer production times. Initial investment in automated soldering equipment can be high, but the long-term savings in rework, material waste, and process consistency often justify the expense. Hand soldering remains cost-effective for small-scale or prototype projects where automation setup costs outweigh benefits.

Speed and Efficiency Comparison

Automated soldering delivers significantly faster processing speeds by utilizing precise robotic arms that consistently apply solder, reducing cycle times compared to manual hand soldering. Efficiency is enhanced through automation's ability to maintain uniform quality, minimize human error, and facilitate continuous production runs without fatigue. Hand soldering, while flexible for small-scale or intricate tasks, generally cannot match the throughput and repeatability achieved by automated soldering systems.

Flexibility and Customization Potential

Automated soldering offers high precision and repeatability but can be limited in flexibility when handling complex or custom designs, often requiring reprogramming or specialized fixtures. Hand soldering excels in customization potential, allowing skilled technicians to adapt techniques on-the-fly for diverse components and irregular layouts. Choosing between these methods depends on the project's complexity, volume, and the need for tailored soldering approaches.

Common Applications for Each Soldering Method

Automated soldering is widely used in mass production environments such as electronics manufacturing for smartphones, computers, and automotive circuits, where precision and speed are critical. Hand soldering is typically favored for repair work, prototyping, and small-scale projects like DIY electronics and custom circuit boards that require detailed manual control. Each method suits specific applications based on volume, complexity, and the need for consistency in solder joints.

Choosing the Right Soldering Method for Your Project

Automated soldering offers consistent precision and faster production rates ideal for large-scale projects or complex circuit boards, reducing human error significantly. Hand soldering provides greater flexibility and control, making it suitable for prototyping, small batches, or intricate repairs where delicate adjustments are needed. Evaluating project volume, complexity, and budget ensures the selection of the most efficient and cost-effective soldering method for optimal results.

Automated Soldering vs Hand Soldering Infographic

productdif.com

productdif.com