Hex keys and Torx keys serve distinct purposes in tool pet applications, with hex keys featuring a six-sided design ideal for general fastening tasks due to their simplicity and widespread compatibility. Torx keys, characterized by a star-shaped pattern, offer superior torque transfer and reduced cam-out, making them preferable for precision work and applications requiring secure fastening. Selecting between hex and Torx keys depends on the specific tool pet maintenance needs, balancing ease of use and required torque performance.

Table of Comparison

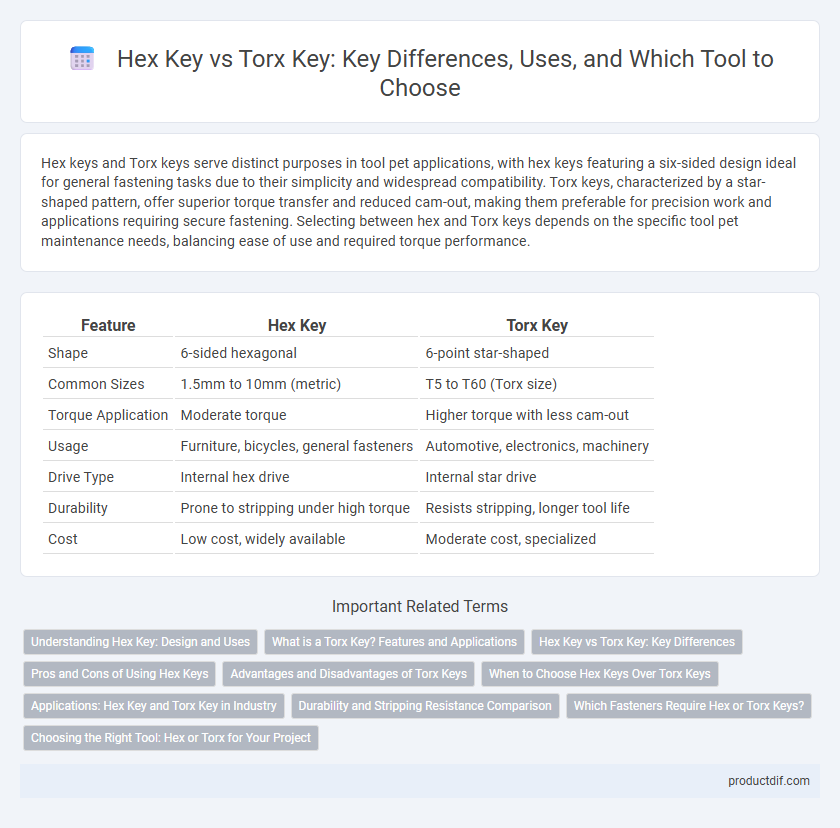

| Feature | Hex Key | Torx Key |

|---|---|---|

| Shape | 6-sided hexagonal | 6-point star-shaped |

| Common Sizes | 1.5mm to 10mm (metric) | T5 to T60 (Torx size) |

| Torque Application | Moderate torque | Higher torque with less cam-out |

| Usage | Furniture, bicycles, general fasteners | Automotive, electronics, machinery |

| Drive Type | Internal hex drive | Internal star drive |

| Durability | Prone to stripping under high torque | Resists stripping, longer tool life |

| Cost | Low cost, widely available | Moderate cost, specialized |

Understanding Hex Key: Design and Uses

Hex keys, also known as Allen wrenches, feature a simple L-shaped design with a hexagonal cross-section that fits into hexagonal socket screws. Commonly used in furniture assembly, bicycle maintenance, and machinery repair, hex keys offer precise torque and easy accessibility in tight spaces. Their widespread compatibility with hex socket fasteners makes them indispensable for DIY projects and professional applications alike.

What is a Torx Key? Features and Applications

A Torx key, also known as a star key, features a six-pointed star-shaped tip designed to provide better grip and torque transfer compared to traditional hex keys. Commonly used in automotive, electronics, and mechanical applications, Torx keys minimize cam-out and wear on fasteners, enhancing durability and precision. Their unique design allows for higher torque application without damaging the screw head, making them ideal for high-torque environments and tamper-resistant fastening.

Hex Key vs Torx Key: Key Differences

Hex keys feature a simple six-sided design ideal for driving screws with hexagonal sockets, offering ease of use in tight spaces. Torx keys have a star-shaped profile with six rounded points, providing superior grip and resisting cam-out under high torque conditions. The primary differences between hex keys and Torx keys lie in their socket shapes, torque capacity, and suitability for specific fasteners in automotive and electronic applications.

Pros and Cons of Using Hex Keys

Hex keys offer simplicity and affordability, making them ideal for basic assembly and maintenance tasks where precision is less critical. Their widespread availability and compatibility with various fasteners enhance versatility, but they may lack the torque capacity and grip security found in Torx keys, leading to potential stripping or wear on fasteners. Hex keys perform well in low-stress applications but can struggle with high-torque or repetitive use scenarios compared to the more robust Torx key design.

Advantages and Disadvantages of Torx Keys

Torx keys offer superior torque transmission compared to hex keys, reducing the risk of cam-out and stripping fasteners, which enhances durability and safety in applications requiring high precision. Their star-shaped design allows for greater surface contact, improving grip and minimizing wear on both the tool and fastener, making them ideal for automotive and electronic assembly. However, Torx keys may require specialized sets that are less commonly available and sometimes more expensive, which can be a drawback for general-purpose use and casual tool users.

When to Choose Hex Keys Over Torx Keys

Hex keys are ideal for applications requiring simple, quick adjustments and strong torque control, especially in furniture assembly and bicycle maintenance where standard fasteners prevail. Their widespread compatibility with hexagonal socket screws and cost-effectiveness make them preferable for general-purpose use and DIY projects. Hex keys excel in situations demanding ease of use and accessibility in tight spaces without specialized fastening requirements.

Applications: Hex Key and Torx Key in Industry

Hex keys are widely used in machinery assembly, furniture manufacturing, and automotive repair due to their ability to fit into recessed hexagonal sockets, providing strong torque in confined spaces. Torx keys are preferred in precision industries such as electronics, aerospace, and automotive manufacturing for their star-shaped design, which reduces cam-out and allows higher torque transfer. Both tools are essential in industrial settings but serve distinct purposes based on torque requirements and tool accessibility.

Durability and Stripping Resistance Comparison

Hex keys typically offer moderate durability with a higher risk of stripping due to their six-point contact design, which concentrates torque on fewer surfaces. Torx keys feature a star-shaped six-lobed pattern that distributes torque more evenly, significantly enhancing stripping resistance and extending tool lifespan. In industrial and heavy-use applications, Torx keys outperform hex keys by maintaining integrity under high-stress conditions, making them the preferred choice for durability and wear resistance.

Which Fasteners Require Hex or Torx Keys?

Hex keys are designed for fasteners with hexagonal recessed sockets commonly found in furniture assembly, bicycle components, and machinery requiring moderate torque. Torx keys fit star-shaped fasteners that provide higher torque transfer and resistance to cam-out, often used in automotive parts, electronics, and security applications. Choosing between hex or torx keys depends on the fastener type, with hex for general use and torx for precision and enhanced grip in demanding environments.

Choosing the Right Tool: Hex or Torx for Your Project

Hex keys offer a versatile and widely compatible solution for fasteners with six-sided recesses commonly used in furniture assembly and bicycle maintenance. Torx keys provide enhanced torque transfer and reduced cam-out for applications requiring durability and precision, such as automotive or electronics repair. Selecting the right tool depends on the fastener type and project demands, ensuring optimal grip and efficiency.

Hex Key vs Torx Key Infographic

productdif.com

productdif.com