Press fit tools create a secure, interference-tight connection by slightly oversizing the tool relative to the hole, ensuring minimal movement and enhanced stability during use. Slip fit tools offer easy insertion and removal with a close tolerance fit, allowing flexibility but less rigid support compared to press fits. Selecting between press fit and slip fit depends on the balance needed between assembly ease and the strength of the connection in pet grooming tools or equipment.

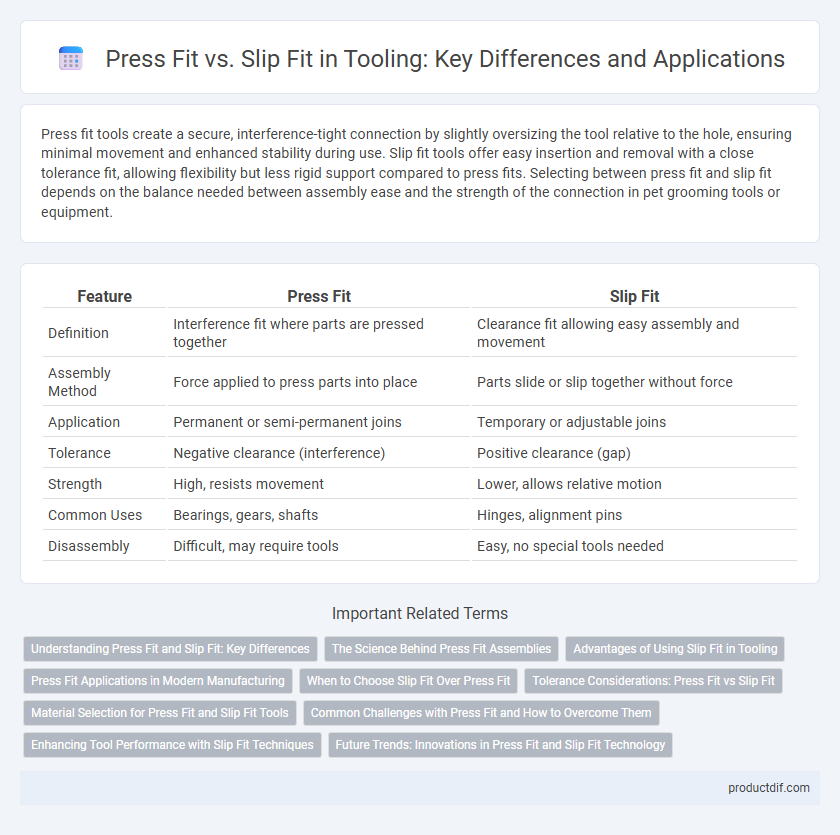

Table of Comparison

| Feature | Press Fit | Slip Fit |

|---|---|---|

| Definition | Interference fit where parts are pressed together | Clearance fit allowing easy assembly and movement |

| Assembly Method | Force applied to press parts into place | Parts slide or slip together without force |

| Application | Permanent or semi-permanent joins | Temporary or adjustable joins |

| Tolerance | Negative clearance (interference) | Positive clearance (gap) |

| Strength | High, resists movement | Lower, allows relative motion |

| Common Uses | Bearings, gears, shafts | Hinges, alignment pins |

| Disassembly | Difficult, may require tools | Easy, no special tools needed |

Understanding Press Fit and Slip Fit: Key Differences

Press fit and slip fit are crucial mechanical assembly techniques used to join parts without fasteners, depending on the interference or clearance between components. Press fit involves a slight interference where the shaft is larger than the hole, creating a tight, secure connection through friction, ideal for permanent assemblies. Slip fit, by contrast, features clearance with slightly smaller shaft dimensions relative to the hole, allowing easy assembly and disassembly with minimal friction, suitable for components requiring frequent maintenance or rotation.

The Science Behind Press Fit Assemblies

Press fit assemblies rely on the interference between mating parts to generate a secure connection through frictional force. This interference creates elastic deformation in the components, enhancing mechanical strength and resistance to vibrations and shear forces. Precise tolerance calculations and material properties are critical to achieving optimal press fit performance without causing damage.

Advantages of Using Slip Fit in Tooling

Slip fit tooling offers increased ease of assembly and disassembly, reducing production time and minimizing the risk of component damage. Its inherent tolerance flexibility accommodates slight variations in part dimensions, enhancing compatibility and improving overall manufacturing efficiency. This method also facilitates maintenance and replacement processes, lowering downtime and operational costs.

Press Fit Applications in Modern Manufacturing

Press fit applications dominate modern manufacturing by ensuring strong mechanical joints without adhesives or welding, commonly used in assembling gears, bearings, and shafts. The high interference tolerance in press fits provides superior load transfer, vibration resistance, and precision alignment essential for aerospace, automotive, and heavy machinery industries. This technique enhances durability and reduces assembly time, making it a preferred method for high-performance, high-stress components.

When to Choose Slip Fit Over Press Fit

Slip fit should be chosen over press fit when frequent assembly and disassembly are required, or when components need to move relative to each other without interference. Applications involving delicate parts or where minimal force is necessary benefit from slip fits due to their looser tolerance and easier alignment. Slip fits are ideal in scenarios prioritizing ease of maintenance and reduced risk of damage compared to the tight interference of press fits.

Tolerance Considerations: Press Fit vs Slip Fit

Tolerance considerations for press fit require significantly tighter dimensional control to ensure an interference fit that maintains part alignment and prevents movement under load. Slip fit tolerances allow for slight clearance between mating components, enabling easy assembly and disassembly without compromising functionality. Engineers must specify precise tolerance ranges based on material properties and application requirements to achieve optimal performance in press fit and slip fit assemblies.

Material Selection for Press Fit and Slip Fit Tools

Material selection for press fit tools prioritizes high-strength alloys like hardened steel or stainless steel to withstand the intense interference forces and prevent deformation during assembly. Slip fit tools typically use softer, more ductile materials such as aluminum or mild steel to allow smooth, easy insertion without damaging the mating components. Proper material choice enhances tool durability and assembly reliability in both press fit and slip fit applications.

Common Challenges with Press Fit and How to Overcome Them

Press fit assemblies frequently face challenges such as material deformation, misalignment, and excessive insertion force, leading to potential damage or reduced performance. Overcoming these issues requires precise control of tolerances, proper lubrication, and the use of specialized press-fit tools designed to ensure uniform force distribution. Implementing thorough inspection protocols and selecting materials with compatible hardness can also minimize defects and improve overall assembly reliability.

Enhancing Tool Performance with Slip Fit Techniques

Slip fit techniques improve tool performance by allowing precise alignment and easy assembly, reducing wear and extending tool lifespan. Unlike press fit, slip fit minimizes stress on components, enhancing operational efficiency and reducing the risk of damage. Optimizing tolerances for slip fit ensures consistent, repeatable results in high-precision tooling applications.

Future Trends: Innovations in Press Fit and Slip Fit Technology

Future trends in press fit and slip fit technology emphasize the integration of smart materials and precision engineering for enhanced performance and durability. Innovations such as adaptive fit mechanisms and real-time monitoring sensors are being developed to optimize fit accuracy and reduce assembly errors. These advancements promise to revolutionize manufacturing processes by improving reliability and enabling automated quality control.

Press Fit vs Slip Fit Infographic

productdif.com

productdif.com