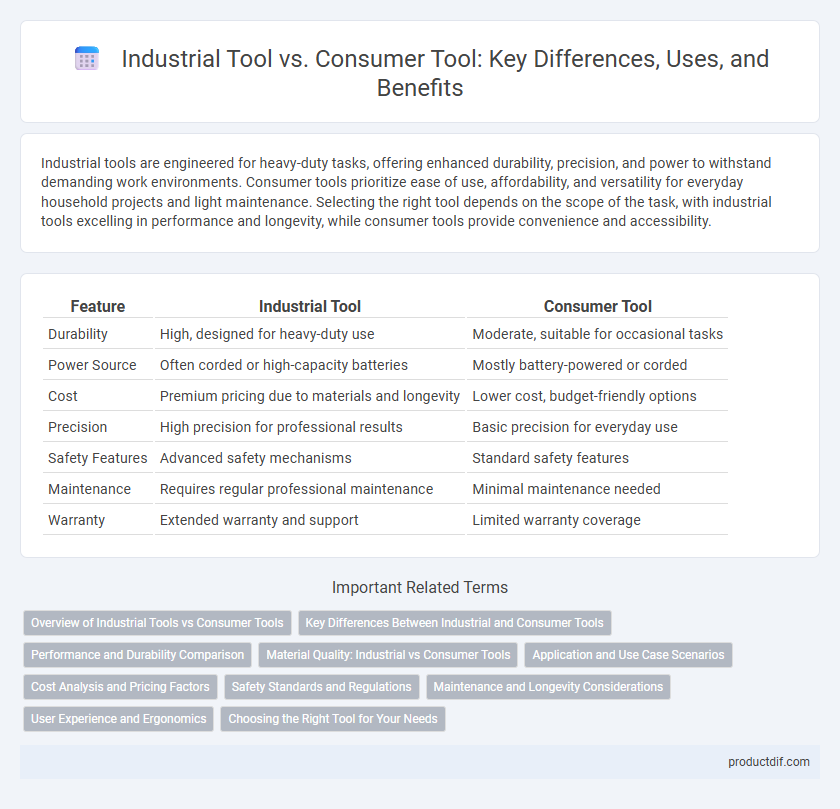

Industrial tools are engineered for heavy-duty tasks, offering enhanced durability, precision, and power to withstand demanding work environments. Consumer tools prioritize ease of use, affordability, and versatility for everyday household projects and light maintenance. Selecting the right tool depends on the scope of the task, with industrial tools excelling in performance and longevity, while consumer tools provide convenience and accessibility.

Table of Comparison

| Feature | Industrial Tool | Consumer Tool |

|---|---|---|

| Durability | High, designed for heavy-duty use | Moderate, suitable for occasional tasks |

| Power Source | Often corded or high-capacity batteries | Mostly battery-powered or corded |

| Cost | Premium pricing due to materials and longevity | Lower cost, budget-friendly options |

| Precision | High precision for professional results | Basic precision for everyday use |

| Safety Features | Advanced safety mechanisms | Standard safety features |

| Maintenance | Requires regular professional maintenance | Minimal maintenance needed |

| Warranty | Extended warranty and support | Limited warranty coverage |

Overview of Industrial Tools vs Consumer Tools

Industrial tools are designed for heavy-duty applications, featuring enhanced durability, higher power output, and specialized functionalities to meet rigorous workplace demands. Consumer tools prioritize ease of use, portability, and affordability, catering to DIY enthusiasts and household projects with less frequent usage requirements. The choice between industrial and consumer tools depends on specific needs regarding performance, longevity, and intended usage environment.

Key Differences Between Industrial and Consumer Tools

Industrial tools are designed for durability, high performance, and continuous use in demanding environments, often featuring advanced materials and higher power ratings. Consumer tools prioritize ease of use, affordability, and portability, catering primarily to occasional or light-duty tasks. The key differences between industrial and consumer tools lie in build quality, power capacity, and intended usage frequency.

Performance and Durability Comparison

Industrial tools outperform consumer tools in performance due to their high-powered motors, precision engineering, and ability to sustain continuous heavy-duty use. Durability in industrial tools is enhanced by robust materials such as hardened steel and reinforced housings that resist wear and withstand harsh working environments. Consumer tools, while adequate for occasional tasks, typically feature lighter construction and lower-grade components, resulting in reduced lifespan and limited performance under intensive workloads.

Material Quality: Industrial vs Consumer Tools

Industrial tools are crafted from high-grade alloy steels and tempered metals to withstand rigorous, continuous use in demanding environments, ensuring superior durability and longevity. Consumer tools typically use lower-grade materials and less robust manufacturing processes, which limits their lifespan and performance under heavy workload. Material quality directly impacts the tool's resistance to wear, corrosion, and mechanical stress, making industrial tools more reliable for professional applications.

Application and Use Case Scenarios

Industrial tools are designed for heavy-duty applications such as manufacturing, construction, and metalwork, offering enhanced durability and precision to withstand rigorous and continuous use in demanding environments. Consumer tools cater to general household repairs, DIY projects, and light maintenance tasks, emphasizing ease of use, portability, and affordability for non-professional users. The choice between industrial and consumer tools depends on the intensity of the application, required tool lifespan, and user expertise in specific use case scenarios.

Cost Analysis and Pricing Factors

Industrial tools generally command higher prices due to their enhanced durability, precision, and compliance with stringent safety standards, which contribute to greater upfront costs. Pricing factors include material quality, manufacturing complexity, and long-term reliability essential for heavy-duty applications, contrasting with consumer tools that prioritize affordability and ease of use. Cost analysis reveals industrial tools' investment in advanced technology and maintenance support, justifying their elevated price point to meet commercial demands.

Safety Standards and Regulations

Industrial tools adhere to stringent safety standards such as OSHA and ANSI to ensure workplace protection and compliance with regulatory requirements, while consumer tools follow less rigorous standards governed by bodies like the Consumer Product Safety Commission (CPSC). Industrial tools incorporate advanced safety features, including reinforced guards and automatic shut-off mechanisms, to mitigate risks in high-use, hazardous environments. Consumer tools prioritize ease of use and basic safety measures suitable for occasional or household applications, reflecting differing regulatory frameworks and usage contexts.

Maintenance and Longevity Considerations

Industrial tools require robust maintenance schedules to ensure durability under heavy, continuous use, often featuring modular components for easy replacement and repair. Consumer tools prioritize ease of maintenance with simpler designs and less frequent servicing due to intermittent usage patterns. Longevity in industrial tools is enhanced by high-grade materials and precision engineering, whereas consumer tools focus on cost-effective durability suitable for occasional tasks.

User Experience and Ergonomics

Industrial tools prioritize durability and precision, designed for prolonged use in demanding environments, enhancing user experience by reducing fatigue with ergonomic grips and balanced weight distribution. Consumer tools emphasize ease of use and safety features, incorporating ergonomic designs that accommodate less experienced users and shorter usage periods. Ergonomic improvements in both sectors aim to minimize strain, improve control, and increase overall efficiency.

Choosing the Right Tool for Your Needs

Selecting the right industrial tool versus a consumer tool depends on the scale, durability, and precision required for the task. Industrial tools are designed for heavy-duty use with robust materials and higher performance standards, making them ideal for construction, manufacturing, or professional settings. Consumer tools, often more affordable and user-friendly, suit occasional or light-duty projects, ensuring efficiency without the need for industrial-grade specifications.

Industrial Tool vs Consumer Tool Infographic

productdif.com

productdif.com