Press-fit assembly offers a mechanical connection by forcing components together, ensuring a strong and reliable joint without the need for chemicals. Adhesive bonding provides flexibility in joining different materials and distributes stress evenly, enhancing overall durability. Selecting between these methods depends on application requirements such as load capacity, environmental resistance, and assembly complexity.

Table of Comparison

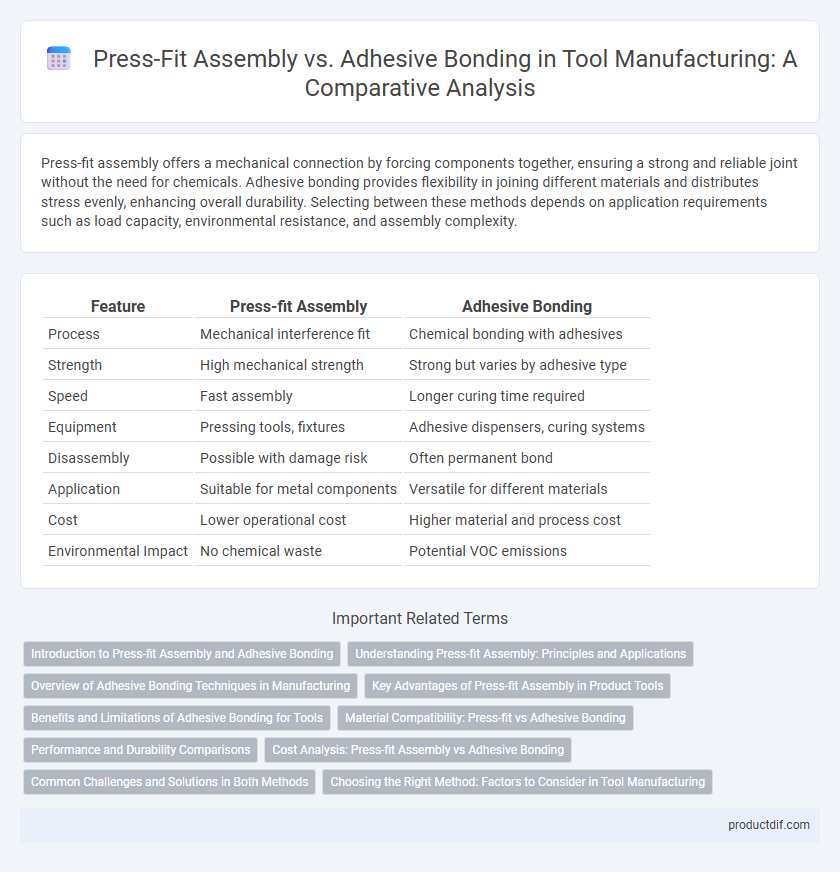

| Feature | Press-fit Assembly | Adhesive Bonding |

|---|---|---|

| Process | Mechanical interference fit | Chemical bonding with adhesives |

| Strength | High mechanical strength | Strong but varies by adhesive type |

| Speed | Fast assembly | Longer curing time required |

| Equipment | Pressing tools, fixtures | Adhesive dispensers, curing systems |

| Disassembly | Possible with damage risk | Often permanent bond |

| Application | Suitable for metal components | Versatile for different materials |

| Cost | Lower operational cost | Higher material and process cost |

| Environmental Impact | No chemical waste | Potential VOC emissions |

Introduction to Press-fit Assembly and Adhesive Bonding

Press-fit assembly relies on the interference between tightly fitted components to create a secure mechanical joint without additional materials, offering high strength and ease of disassembly. Adhesive bonding utilizes specialized adhesives to chemically bond surfaces, providing uniform stress distribution and sealing properties for complex geometries. Both methods are essential in manufacturing, with press-fit favored for metal assemblies and adhesive bonding preferred for lightweight or composite materials.

Understanding Press-fit Assembly: Principles and Applications

Press-fit assembly relies on the interference between tightly fitting components to create a secure mechanical joint without adhesives, exploiting precise dimensional tolerances for optimal retention and load distribution. This method is widely applied in automotive, aerospace, and electronics manufacturing due to its clean, fast, and reliable connection process that enhances structural integrity. Understanding the principles of press-fit assembly involves mastering factors such as material elasticity, surface finish, insertion force, and thermal expansion to ensure effective and durable joins.

Overview of Adhesive Bonding Techniques in Manufacturing

Adhesive bonding techniques in manufacturing involve joining materials by applying a polymer-based adhesive that cures to form a strong, uniform bond, enhancing structural integrity without mechanical fasteners. This method supports various substrates such as metals, plastics, and composites, offering benefits like stress distribution, vibration damping, and weight reduction. Common adhesive types include epoxy, polyurethane, and acrylic, each selected based on factors like curing time, environmental resistance, and load-bearing capacity, making adhesive bonding a versatile alternative to traditional press-fit assembly.

Key Advantages of Press-fit Assembly in Product Tools

Press-fit assembly offers key advantages in product tools by providing rapid, consistent, and reliable joints without the need for curing time or chemical adhesives. It ensures high mechanical strength and precise alignment through controlled interference fits, reducing assembly errors and maintenance requirements. This method enhances production efficiency and sustainability by eliminating adhesive waste and simplifying disassembly for repairs or recycling.

Benefits and Limitations of Adhesive Bonding for Tools

Adhesive bonding in tool assembly offers benefits such as uniform stress distribution, resistance to vibration, and the ability to join dissimilar materials without causing thermal distortion. It enables cleaner aesthetics and reduces the need for mechanical fasteners, minimizing stress concentrations and corrosion risks. However, limitations include sensitivity to surface preparation, curing time requirements, and potential degradation under extreme temperature or chemical exposure.

Material Compatibility: Press-fit vs Adhesive Bonding

Press-fit assembly offers excellent material compatibility for metals and rigid plastics, creating strong mechanical interlocks without altering surface chemistry. Adhesive bonding provides versatility for bonding dissimilar materials, including ceramics, composites, and various polymers, by forming molecular-level adhesion. Material selection depends on factors like thermal expansion, surface energy, and chemical resistance to ensure durability and performance in the target application.

Performance and Durability Comparisons

Press-fit assembly provides superior mechanical strength and immediate load-bearing capacity, making it ideal for high-stress applications. Adhesive bonding offers enhanced resistance to corrosion and environmental factors, contributing to long-term durability especially in complex geometries. Performance depends on material compatibility and operating conditions, with press-fit excelling in precision and adhesives outperforming in flexibility and sealing.

Cost Analysis: Press-fit Assembly vs Adhesive Bonding

Press-fit assembly generally incurs lower upfront equipment costs compared to adhesive bonding, which requires specialized dispensing systems and curing ovens. In terms of operational expenses, adhesive bonding often demands longer processing times and material costs associated with adhesives, whereas press-fit assembly benefits from faster cycle times and minimal consumables. Maintenance and rework costs tend to be higher in adhesive bonding due to potential adhesive failures, while press-fit assembly offers easier disassembly and part replacement, resulting in overall cost efficiency.

Common Challenges and Solutions in Both Methods

Press-fit assembly and adhesive bonding both face challenges such as ensuring joint strength and durability under stress and environmental conditions. Common issues include material incompatibility and precise surface preparation, which are critical for optimal adhesion or mechanical interference. Solutions involve selecting appropriate material pairs, employing surface treatments like plasma or chemical cleaning, and controlling process parameters to enhance bond reliability and performance.

Choosing the Right Method: Factors to Consider in Tool Manufacturing

Selecting the optimal joining method in tool manufacturing depends on factors such as load capacity, environmental conditions, and disassembly requirements. Press-fit assembly offers high mechanical strength and ease of maintenance without adhesives, while adhesive bonding provides uniform stress distribution and seals against corrosion. Evaluating material compatibility, precision requirements, and long-term durability ensures the chosen technique maximizes performance and longevity of the tool.

Press-fit assembly vs Adhesive bonding Infographic

productdif.com

productdif.com