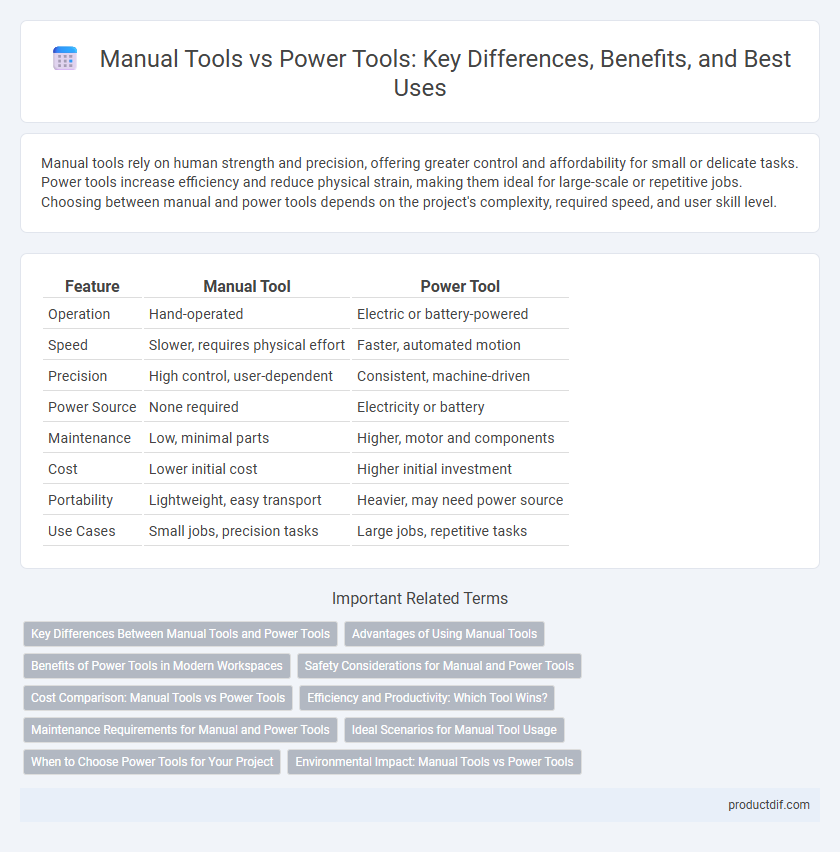

Manual tools rely on human strength and precision, offering greater control and affordability for small or delicate tasks. Power tools increase efficiency and reduce physical strain, making them ideal for large-scale or repetitive jobs. Choosing between manual and power tools depends on the project's complexity, required speed, and user skill level.

Table of Comparison

| Feature | Manual Tool | Power Tool |

|---|---|---|

| Operation | Hand-operated | Electric or battery-powered |

| Speed | Slower, requires physical effort | Faster, automated motion |

| Precision | High control, user-dependent | Consistent, machine-driven |

| Power Source | None required | Electricity or battery |

| Maintenance | Low, minimal parts | Higher, motor and components |

| Cost | Lower initial cost | Higher initial investment |

| Portability | Lightweight, easy transport | Heavier, may need power source |

| Use Cases | Small jobs, precision tasks | Large jobs, repetitive tasks |

Key Differences Between Manual Tools and Power Tools

Manual tools rely solely on human effort for operation, offering precise control and portability without the need for electrical power. Power tools use electricity or batteries to increase efficiency, speed, and force, making them ideal for repetitive or heavy-duty tasks. Key differences include energy source, operational speed, and user effort, with power tools prioritizing productivity and manual tools emphasizing accuracy and simplicity.

Advantages of Using Manual Tools

Manual tools offer unparalleled precision and control for delicate tasks that require careful handling, making them ideal for intricate craftsmanship. They do not rely on electricity or batteries, ensuring reliability and usability in remote locations or during power outages. Furthermore, manual tools are generally lighter, more affordable, and safer, reducing the risk of accidents and maintenance costs associated with power tools.

Benefits of Power Tools in Modern Workspaces

Power tools significantly enhance productivity in modern workspaces by delivering increased speed and efficiency compared to manual tools. Their consistent power output reduces physical strain, allowing workers to complete tasks with greater precision and less fatigue. Integration of cordless and smart technology in power tools further improves flexibility and safety, making them indispensable for complex or repetitive jobs.

Safety Considerations for Manual and Power Tools

Manual tools generally present fewer safety risks as they operate at human-controlled speeds and require physical effort, reducing the chances of accidental injury from rapid movements. Power tools, while increasing efficiency, demand rigorous safety precautions such as proper personal protective equipment (PPE), regular maintenance, and adherence to manufacturer guidelines to prevent accidents like electric shocks, cuts, or amputations. Understanding ergonomic design and keeping tools in good condition are essential for minimizing musculoskeletal injuries and ensuring safe operation of both manual and power tools.

Cost Comparison: Manual Tools vs Power Tools

Manual tools generally have a lower initial cost compared to power tools, making them more accessible for basic tasks and occasional use. Power tools, while more expensive upfront, can enhance efficiency and reduce labor time, potentially leading to long-term savings on professional projects. Maintenance and energy costs should also be considered, as manual tools require minimal upkeep, whereas power tools may incur additional expenses for batteries, electricity, or repairs.

Efficiency and Productivity: Which Tool Wins?

Manual tools require greater physical effort and time to complete tasks, significantly limiting efficiency and productivity. Power tools, driven by electricity or batteries, deliver faster operation and consistent performance, reducing labor intensity and increasing output. For professionals seeking to maximize work speed and accuracy, power tools clearly outperform manual tools in efficiency and productivity metrics.

Maintenance Requirements for Manual and Power Tools

Manual tools typically require minimal maintenance, such as regular cleaning, sharpening, and lubrication of moving parts to ensure longevity and optimal performance. Power tools demand more comprehensive upkeep, including monitoring electrical components, replacing worn-out brushes, tightening fasteners, and inspecting batteries or cords to prevent malfunctions. Proper maintenance of power tools involves routine servicing of motors and safety features to sustain efficiency and extend operational life.

Ideal Scenarios for Manual Tool Usage

Manual tools are ideal for tasks requiring precision, control, and minimal vibration, such as fine woodworking, delicate repairs, or detailed craftsmanship. They perform well in environments without access to electricity or where portability and quiet operation are essential. Manual tools excel in low-volume or beginner projects, where accuracy and tactile feedback are critical for quality results.

When to Choose Power Tools for Your Project

Power tools offer increased efficiency, precision, and speed for complex or large-scale projects where consistent results are essential. When tasks involve repetitive motions, dense materials, or require high torque, power tools significantly reduce physical strain and save time. Opt for power tools in construction, woodworking, or metalworking projects to achieve professional-grade outcomes with enhanced safety features.

Environmental Impact: Manual Tools vs Power Tools

Manual tools generate minimal environmental impact due to their reliance on human energy, producing no direct emissions or electronic waste. Power tools depend on electricity or batteries, contributing to carbon emissions and resource consumption during production and operation. Choosing manual tools over power tools can significantly reduce a user's carbon footprint and electronic waste output.

Manual Tool vs Power Tool Infographic

productdif.com

productdif.com