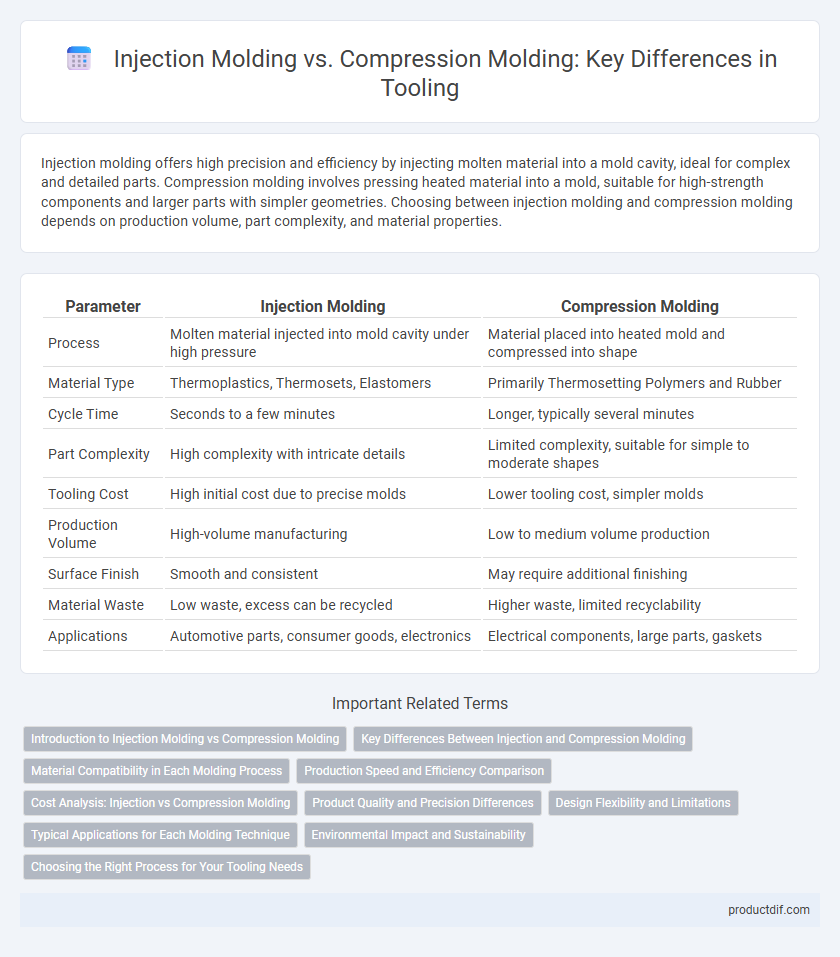

Injection molding offers high precision and efficiency by injecting molten material into a mold cavity, ideal for complex and detailed parts. Compression molding involves pressing heated material into a mold, suitable for high-strength components and larger parts with simpler geometries. Choosing between injection molding and compression molding depends on production volume, part complexity, and material properties.

Table of Comparison

| Parameter | Injection Molding | Compression Molding |

|---|---|---|

| Process | Molten material injected into mold cavity under high pressure | Material placed into heated mold and compressed into shape |

| Material Type | Thermoplastics, Thermosets, Elastomers | Primarily Thermosetting Polymers and Rubber |

| Cycle Time | Seconds to a few minutes | Longer, typically several minutes |

| Part Complexity | High complexity with intricate details | Limited complexity, suitable for simple to moderate shapes |

| Tooling Cost | High initial cost due to precise molds | Lower tooling cost, simpler molds |

| Production Volume | High-volume manufacturing | Low to medium volume production |

| Surface Finish | Smooth and consistent | May require additional finishing |

| Material Waste | Low waste, excess can be recycled | Higher waste, limited recyclability |

| Applications | Automotive parts, consumer goods, electronics | Electrical components, large parts, gaskets |

Introduction to Injection Molding vs Compression Molding

Injection molding involves forcing molten material into a mold cavity under high pressure, allowing for precise and complex shapes with rapid production cycles ideal for mass manufacturing. Compression molding uses heat and pressure to shape pre-measured material placed directly into an open mold, better suited for large, simple parts with stronger structural integrity. Both processes are essential in manufacturing, with injection molding offering higher detail and speed, while compression molding provides cost-effective solutions for durable components.

Key Differences Between Injection and Compression Molding

Injection molding uses high pressure to inject molten material into a mold, enabling precise and complex shapes with fast cycle times, ideal for mass production of intricate components. Compression molding involves placing a pre-measured amount of material into an open mold cavity, then applying heat and pressure to shape it, making it suitable for large, thick parts and composites with lower tooling costs. Key differences include injection molding's ability to produce highly detailed geometries quickly versus compression molding's efficiency with heavy-duty parts and thermosetting materials, impacting production scale, surface finish, and material versatility.

Material Compatibility in Each Molding Process

Injection molding excels with thermoplastics such as ABS, polyethylene, and polycarbonate due to its ability to precisely control temperature and pressure, enabling consistent material flow and complex part geometries. Compression molding is better suited for thermosetting polymers like epoxy, phenolic, and silicone rubber, which require heat and pressure to cure into rigid, durable shapes. Material compatibility in each process directly impacts product performance, cycle time, and manufacturing cost efficiency.

Production Speed and Efficiency Comparison

Injection molding offers significantly faster production speeds compared to compression molding, with cycle times often measured in seconds due to automated processes. Compression molding generally has longer cycle times, ranging from 1 to 5 minutes per part, which reduces throughput in high-volume manufacturing. The efficiency of injection molding is enhanced by precise material control and minimal waste, making it ideal for large-scale mass production, whereas compression molding is more suitable for lower volume production with thicker, more durable parts.

Cost Analysis: Injection vs Compression Molding

Injection molding typically incurs higher upfront costs due to expensive molds and machinery but offers lower per-unit costs in large production runs, making it cost-effective for high-volume manufacturing. Compression molding features lower initial tool expenses and simpler equipment, which makes it suitable for small to medium production volumes despite higher per-part labor costs. Choosing between injection and compression molding hinges on production scale, material type, and cost per part targets, with injection molding dominating in efficiency for mass production and compression molding preferred for limited runs or specialized composites.

Product Quality and Precision Differences

Injection molding provides superior product quality with high precision and tight tolerances, ideal for complex geometries and intricate detailing. Compression molding, while effective for large and simple parts, often results in less uniformity and surface finish compared to injection molding. The controlled injection process minimizes defects such as warping and voids, enhancing repeatability and overall dimensional accuracy.

Design Flexibility and Limitations

Injection molding offers superior design flexibility with the ability to produce complex geometries, intricate details, and thin walls, making it ideal for high-volume manufacturing of precise parts. Compression molding is limited by simpler mold designs and thicker part walls, restricting intricate shapes but providing advantages for large, sturdy components made from thermoset materials. The choice between these methods depends on the part's complexity, production volume, and material compatibility, with injection molding excelling in detail and consistency.

Typical Applications for Each Molding Technique

Injection molding is typically used for producing high-volume, complex plastic parts such as automotive components, consumer electronics housings, and medical devices due to its precision and efficiency. Compression molding is favored for manufacturing large, durable items like automotive body panels, electrical insulators, and industrial tooling because it handles reinforced materials and thermosetting plastics effectively. Each molding technique suits distinct applications based on material properties, production volume, and part design requirements.

Environmental Impact and Sustainability

Injection molding produces less material waste due to its high precision and ability to reuse excess plastic, making it more environmentally efficient compared to compression molding, which often generates more scrap and requires higher energy consumption. Compression molding typically uses thermosetting polymers that are difficult to recycle, whereas injection molding primarily uses thermoplastics that offer better recyclability and sustainability benefits. Energy efficiency and waste reduction in injection molding contribute significantly to lower carbon footprints and enhanced environmental sustainability in manufacturing processes.

Choosing the Right Process for Your Tooling Needs

Injection molding offers high precision and fast cycle times ideal for complex tooling designs and large production runs, while compression molding excels in processing large, durable parts with superior strength and minimal material waste. Selecting the right process depends on factors such as part complexity, material type, production volume, and cost efficiency. Assessing tooling requirements against these parameters ensures optimal performance and long-term durability of the manufactured components.

Injection Molding vs Compression Molding Infographic

productdif.com

productdif.com