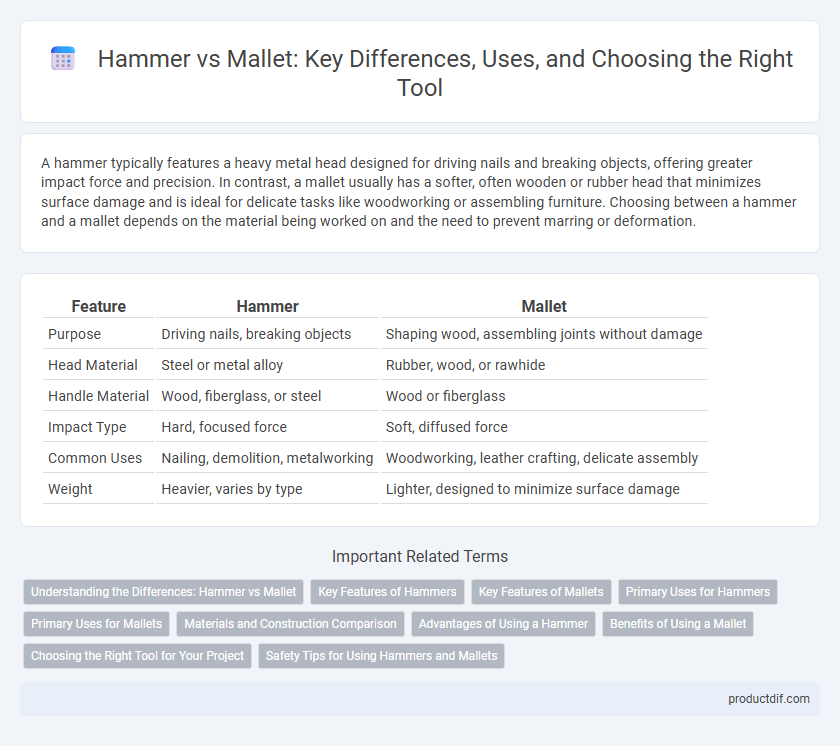

A hammer typically features a heavy metal head designed for driving nails and breaking objects, offering greater impact force and precision. In contrast, a mallet usually has a softer, often wooden or rubber head that minimizes surface damage and is ideal for delicate tasks like woodworking or assembling furniture. Choosing between a hammer and a mallet depends on the material being worked on and the need to prevent marring or deformation.

Table of Comparison

| Feature | Hammer | Mallet |

|---|---|---|

| Purpose | Driving nails, breaking objects | Shaping wood, assembling joints without damage |

| Head Material | Steel or metal alloy | Rubber, wood, or rawhide |

| Handle Material | Wood, fiberglass, or steel | Wood or fiberglass |

| Impact Type | Hard, focused force | Soft, diffused force |

| Common Uses | Nailing, demolition, metalworking | Woodworking, leather crafting, delicate assembly |

| Weight | Heavier, varies by type | Lighter, designed to minimize surface damage |

Understanding the Differences: Hammer vs Mallet

A hammer features a heavy metal head designed for driving nails and breaking objects, offering high-impact force on hard materials. A mallet typically has a softer, wooden or rubber head intended for more delicate tasks like shaping wood or assembling joints without damaging surfaces. Understanding the differences in head material and intended use helps select the right tool for precision or heavy-duty work.

Key Features of Hammers

Hammers feature a heavy metal head and a sturdy handle designed for driving nails, breaking objects, and fitting parts, providing high impact force through their weighted striking surface. The claw hammer variant includes a curved claw for efficient nail removal and prying tasks, enhancing versatility on construction sites. Ergonomic handles made from wood, fiberglass, or steel improve grip and reduce user fatigue during repetitive striking activities.

Key Features of Mallets

Mallets feature a large, usually wooden or rubber head designed to deliver softer blows that avoid damaging surfaces, making them ideal for woodworking and delicate tasks. Their lightweight construction and non-marring properties allow for precise control and reduced surface impact compared to hammers. These key features distinguish mallets in applications requiring gentle force and careful handling.

Primary Uses for Hammers

Hammers are primarily designed for driving nails, shaping metal, and breaking objects through a concentrated force delivered by a solid metal head. They are commonly used in construction, carpentry, and metalworking for tasks that require precise impact and durability. Unlike mallets, hammers excel in applications needing a harder striking surface to penetrate, fasten, or deform materials.

Primary Uses for Mallets

Mallets are primarily used for tasks requiring softer impacts, such as woodworking, assembling furniture, and driving chisels without marring the surface. Their rubber, wood, or rawhide heads absorb shock and prevent damage to delicate materials. Mallets provide controlled force ideal for fine carpentry and shaping soft metals.

Materials and Construction Comparison

Hammers typically feature a forged steel head designed for durability and impact, paired with a wooden, fiberglass, or steel handle for strength and shock absorption. Mallets are commonly constructed with a softer, non-metallic head made from rubber, wood, or rawhide, minimizing surface damage during use. The primary material difference lies in the hammer's heavy metal head suited for driving nails, whereas the mallet's softer head protects workpieces during delicate tasks.

Advantages of Using a Hammer

A hammer offers superior durability and impact power, making it ideal for driving nails and breaking hard materials with precision. Its metal head ensures effective force transfer, enhancing work efficiency on construction and carpentry projects. The ergonomic handle design also provides better grip and control, reducing user fatigue during prolonged use.

Benefits of Using a Mallet

Using a mallet provides controlled, softer impacts that prevent surface damage on delicate materials like wood or leather. Its non-metallic head minimizes marring, making it ideal for woodworking, upholstery, and assembling joints without leaving dents. The elastic nature of a mallet ensures consistent force distribution, reducing the risk of material splitting compared to the harder strikes from a hammer.

Choosing the Right Tool for Your Project

Selecting the right tool depends on the material and precision required; a hammer is ideal for driving nails into hard surfaces like wood or metal, providing strong, focused impact. A mallet offers a softer blow suitable for delicate tasks such as woodworking joints or assembling furniture without damaging the surface. Consider the tool's weight, head material, and handle design to match your project's specific demands and ensure efficiency and safety.

Safety Tips for Using Hammers and Mallets

When using hammers and mallets, always wear safety goggles to protect eyes from flying debris and use gloves to improve grip and reduce hand strain. Choose the right tool for the task to avoid damage or accidents, such as using a wooden mallet for delicate woodworking instead of a heavy metal hammer. Inspect tools regularly for cracks or loose handles to ensure safe and effective use.

Hammer vs Mallet Infographic

productdif.com

productdif.com