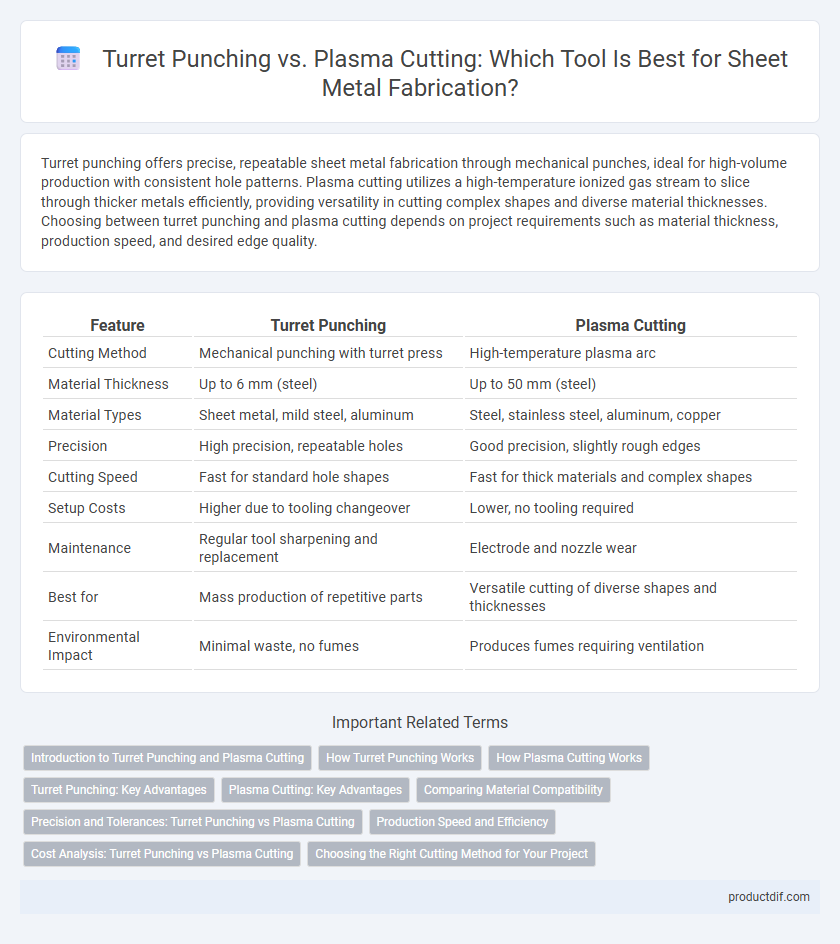

Turret punching offers precise, repeatable sheet metal fabrication through mechanical punches, ideal for high-volume production with consistent hole patterns. Plasma cutting utilizes a high-temperature ionized gas stream to slice through thicker metals efficiently, providing versatility in cutting complex shapes and diverse material thicknesses. Choosing between turret punching and plasma cutting depends on project requirements such as material thickness, production speed, and desired edge quality.

Table of Comparison

| Feature | Turret Punching | Plasma Cutting |

|---|---|---|

| Cutting Method | Mechanical punching with turret press | High-temperature plasma arc |

| Material Thickness | Up to 6 mm (steel) | Up to 50 mm (steel) |

| Material Types | Sheet metal, mild steel, aluminum | Steel, stainless steel, aluminum, copper |

| Precision | High precision, repeatable holes | Good precision, slightly rough edges |

| Cutting Speed | Fast for standard hole shapes | Fast for thick materials and complex shapes |

| Setup Costs | Higher due to tooling changeover | Lower, no tooling required |

| Maintenance | Regular tool sharpening and replacement | Electrode and nozzle wear |

| Best for | Mass production of repetitive parts | Versatile cutting of diverse shapes and thicknesses |

| Environmental Impact | Minimal waste, no fumes | Produces fumes requiring ventilation |

Introduction to Turret Punching and Plasma Cutting

Turret punching utilizes a CNC-controlled turret equipped with various punching tools to efficiently create precise holes and shapes in sheet metal. Plasma cutting employs a high-velocity jet of ionized gas to melt and remove metal, enabling rapid and accurate cutting of conductive materials. Both methods offer distinct advantages in metal fabrication, with turret punching excelling in repetitive hole patterns and plasma cutting providing superior flexibility for complex contours.

How Turret Punching Works

Turret punching operates by utilizing a CNC-controlled turret containing multiple punching tools of various shapes and sizes, which rapidly stamp holes or shapes into sheet metal with precise control. This method excels in producing repetitive, high-precision features by mechanically piercing the material, reducing thermal distortion compared to cutting processes like plasma cutting. The automated turret can quickly switch between tools, enabling efficient fabrication of complex patterns with minimal material waste.

How Plasma Cutting Works

Plasma cutting operates by generating an electrical arc through a gas, transforming it into a high-temperature plasma jet that melts and blows away metal. This cutting process is highly efficient for thick materials and conductive metals, producing precise cuts with a smooth finish. Unlike turret punching, plasma cutting offers versatile shapes without the need for custom tooling, making it ideal for rapid prototyping and complex designs.

Turret Punching: Key Advantages

Turret punching offers precise, high-speed metal sheet fabrication with minimal material waste, making it ideal for complex, repetitive designs. Its automation capabilities reduce labor costs and increase production efficiency compared to plasma cutting. The process delivers clean edges and consistent hole quality without the heat-affected zones commonly associated with plasma cutting.

Plasma Cutting: Key Advantages

Plasma cutting offers precise, high-speed cutting capabilities ideal for thick metal sheets, delivering clean edges with minimal heat distortion. Its versatile application spans various conductive materials, including steel, aluminum, and copper, enhancing productivity in industrial fabrication. The technology also reduces material waste and maintenance costs compared to traditional mechanical cutting methods.

Comparing Material Compatibility

Turret punching excels in processing thin to medium sheet metals like stainless steel, aluminum, and brass with high precision and minimal distortion. Plasma cutting handles thicker materials including carbon steel, stainless steel, and aluminum, offering faster cutting speeds and the ability to cut complex shapes in metals up to several inches thick. Material compatibility depends on thickness and desired finish, with turret punching favored for fine detail in thinner sheets and plasma cutting preferred for rapid, versatile cuts in heavier gauge metals.

Precision and Tolerances: Turret Punching vs Plasma Cutting

Turret punching offers superior precision and tighter tolerances due to its mechanical punching process, achieving accuracy levels often within +-0.1 mm. Plasma cutting, while faster and effective for thicker materials, generally presents wider tolerances around +-0.5 mm and can produce more heat-affected zones. For high-precision applications requiring intricate shapes and consistent dimensions, turret punching is the preferred method over plasma cutting.

Production Speed and Efficiency

Turret punching offers high production speed for repetitive tasks with minimal setup time, making it ideal for sheet metal fabrication involving multiple holes and shapes. Plasma cutting provides faster processing for thicker materials and complex contour cuts but may require slower feed rates and secondary finishing. Efficiency depends on material thickness, detail complexity, and production volume, with turret punching excelling in high-volume, precision hole punching and plasma cutting suited for flexible, fast cutting of varied designs.

Cost Analysis: Turret Punching vs Plasma Cutting

Turret punching generally offers lower operational costs for high-volume sheet metal fabrication due to its efficient material usage and minimal consumable expenses, whereas plasma cutting incurs higher costs from frequent electrode replacements and gas consumption. Initial investment for turret punching machines is typically higher, but long-term savings arise from faster cycle times and less material waste compared to plasma cutting. For businesses prioritizing cost-efficiency in repetitive tasks, turret punching proves more economical, while plasma cutting suits applications needing thicker or more complex cuts despite elevated operational costs.

Choosing the Right Cutting Method for Your Project

Turret punching offers precise hole creation and consistent shapes in sheet metal, making it ideal for high-volume production with complex, repetitive designs. Plasma cutting provides faster, versatile cutting for thicker metals and irregular shapes, suitable for projects requiring speed and flexibility. Selecting the right method depends on material thickness, project complexity, production volume, and the desired edge quality.

Turret Punching vs Plasma Cutting Infographic

productdif.com

productdif.com