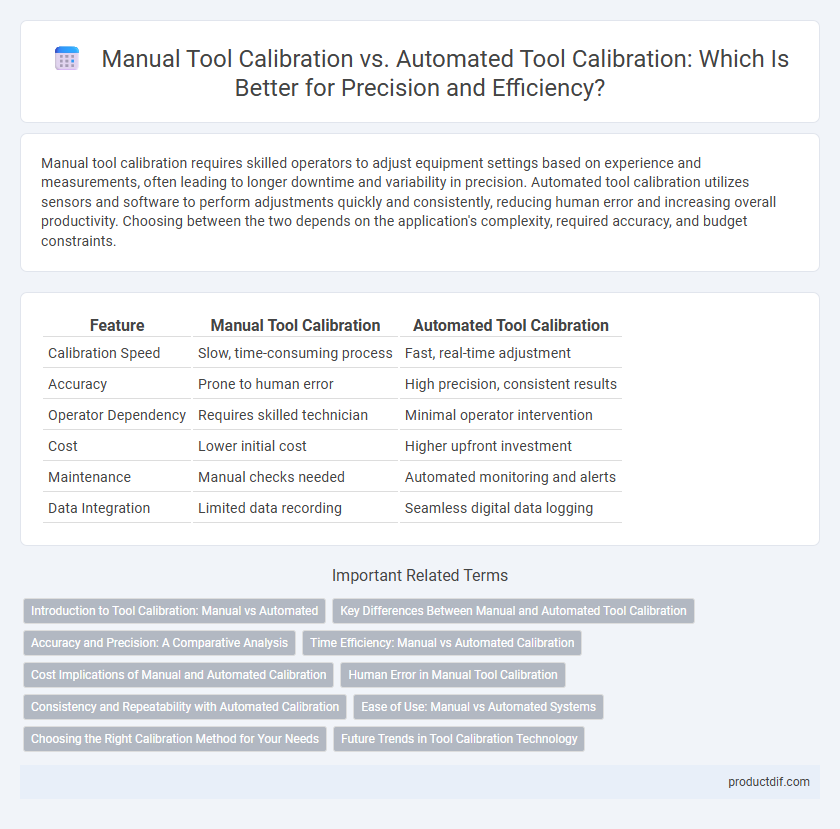

Manual tool calibration requires skilled operators to adjust equipment settings based on experience and measurements, often leading to longer downtime and variability in precision. Automated tool calibration utilizes sensors and software to perform adjustments quickly and consistently, reducing human error and increasing overall productivity. Choosing between the two depends on the application's complexity, required accuracy, and budget constraints.

Table of Comparison

| Feature | Manual Tool Calibration | Automated Tool Calibration |

|---|---|---|

| Calibration Speed | Slow, time-consuming process | Fast, real-time adjustment |

| Accuracy | Prone to human error | High precision, consistent results |

| Operator Dependency | Requires skilled technician | Minimal operator intervention |

| Cost | Lower initial cost | Higher upfront investment |

| Maintenance | Manual checks needed | Automated monitoring and alerts |

| Data Integration | Limited data recording | Seamless digital data logging |

Introduction to Tool Calibration: Manual vs Automated

Tool calibration ensures accuracy and precision in measurement and performance. Manual tool calibration involves skilled technicians adjusting instruments based on reference standards, allowing tailored control but requiring more time and expertise. Automated tool calibration uses software and machinery to perform adjustments quickly and consistently, reducing human error and improving efficiency in industrial settings.

Key Differences Between Manual and Automated Tool Calibration

Manual tool calibration relies on human operators to adjust and verify tool settings, which can introduce variability and longer calibration times. Automated tool calibration utilizes sensors and software algorithms to achieve precise, repeatable measurements, reducing errors and improving efficiency. Key differences include accuracy, consistency, speed, and the level of human involvement in the calibration process.

Accuracy and Precision: A Comparative Analysis

Manual tool calibration relies on the operator's skill and consistency, often resulting in variability that can compromise accuracy and precision. Automated tool calibration utilizes advanced sensors and algorithms to ensure repeatable and highly precise adjustments, significantly reducing human error. Comparative analysis shows automated systems consistently achieve tighter tolerances and more reliable measurement outcomes compared to manual methods.

Time Efficiency: Manual vs Automated Calibration

Automated tool calibration significantly reduces the time required by eliminating repetitive manual adjustments and minimizing human error. Manual tool calibration involves prolonged setup and fine-tuning processes that can delay production schedules and increase downtime. The time efficiency of automated systems enhances overall workflow by providing rapid, precise calibration results with minimal operator intervention.

Cost Implications of Manual and Automated Calibration

Manual tool calibration often involves higher labor costs due to the need for skilled technicians and longer calibration times, increasing overall operational expenses. Automated tool calibration reduces human error and accelerates the calibration process, leading to lower labor costs and improved efficiency. Although automated systems require initial investment, their long-term cost savings and reduced downtime provide significant financial benefits compared to manual methods.

Human Error in Manual Tool Calibration

Manual tool calibration is prone to human error, resulting in inconsistent measurements and reduced accuracy during tool setup and maintenance. Automated tool calibration eliminates much of this error by using precision sensors and software algorithms to ensure repeatable and reliable calibration processes. Reducing human involvement enhances overall tool performance and minimizes downtime caused by calibration inaccuracies.

Consistency and Repeatability with Automated Calibration

Automated tool calibration ensures higher consistency and repeatability by minimizing human error and standardizing measurement processes. Unlike manual calibration, automated systems use precise sensors and software algorithms to maintain uniform calibration standards across multiple tools. This results in reliable accuracy and reduced variability, critical for quality control in manufacturing environments.

Ease of Use: Manual vs Automated Systems

Manual tool calibration requires hands-on adjustments and detailed understanding of calibration procedures, often resulting in longer setup times and potential human errors. Automated tool calibration systems use built-in sensors and software algorithms to quickly and accurately adjust settings, reducing operator workload and minimizing downtime. Ease of use significantly improves with automated calibration, enhancing precision and consistency across repetitive tasks.

Choosing the Right Calibration Method for Your Needs

Choosing between manual and automated tool calibration depends on accuracy requirements, frequency of use, and budget constraints. Manual calibration offers flexibility and cost-effectiveness for low-volume applications, while automated calibration ensures higher precision and consistency in high-throughput environments. Evaluating operational complexity and downtime tolerance is essential to selecting the optimal calibration method for maintaining tool performance.

Future Trends in Tool Calibration Technology

Future trends in tool calibration technology emphasize the integration of automated systems that utilize AI and machine learning for higher precision and reduced human error. Advances in IoT-enabled calibration tools enable real-time data monitoring and predictive maintenance, enhancing operational efficiency. The shift towards automated calibration supports scalable manufacturing processes and consistent quality control in Industry 4.0 environments.

Manual tool calibration vs Automated tool calibration Infographic

productdif.com

productdif.com