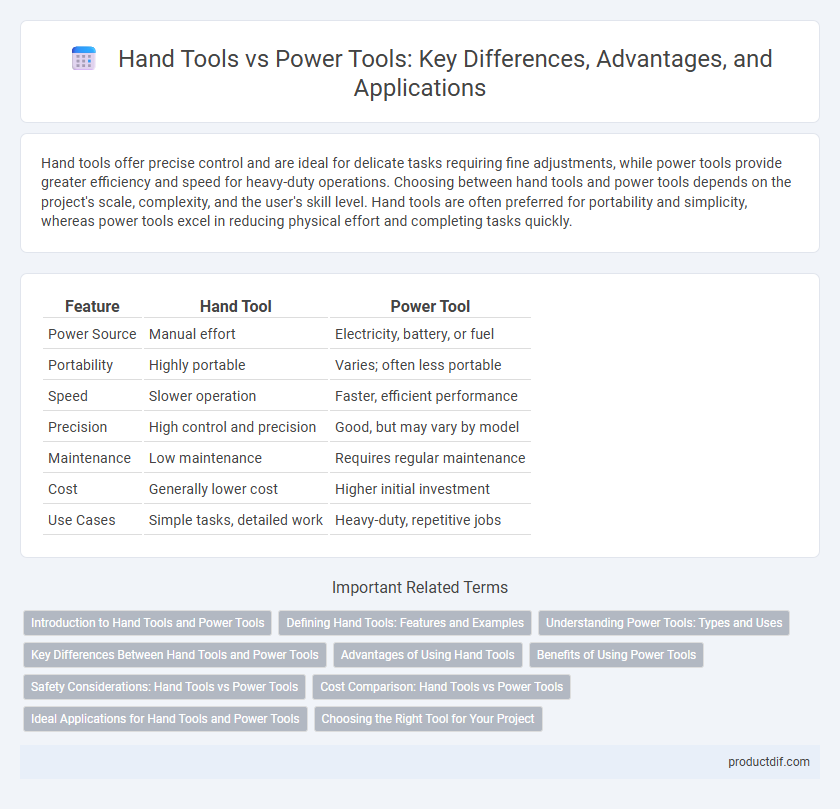

Hand tools offer precise control and are ideal for delicate tasks requiring fine adjustments, while power tools provide greater efficiency and speed for heavy-duty operations. Choosing between hand tools and power tools depends on the project's scale, complexity, and the user's skill level. Hand tools are often preferred for portability and simplicity, whereas power tools excel in reducing physical effort and completing tasks quickly.

Table of Comparison

| Feature | Hand Tool | Power Tool |

|---|---|---|

| Power Source | Manual effort | Electricity, battery, or fuel |

| Portability | Highly portable | Varies; often less portable |

| Speed | Slower operation | Faster, efficient performance |

| Precision | High control and precision | Good, but may vary by model |

| Maintenance | Low maintenance | Requires regular maintenance |

| Cost | Generally lower cost | Higher initial investment |

| Use Cases | Simple tasks, detailed work | Heavy-duty, repetitive jobs |

Introduction to Hand Tools and Power Tools

Hand tools are manually operated devices such as hammers, screwdrivers, and wrenches, designed for precision and control in tasks like woodworking and mechanical repairs. Power tools, including drills, saws, and grinders, leverage electric or battery power to enhance efficiency and reduce physical effort during construction and maintenance projects. Choosing between hand tools and power tools depends on the specific application, required accuracy, and available power sources.

Defining Hand Tools: Features and Examples

Hand tools feature manual operation, relying on human force rather than electricity or batteries, making them ideal for precision tasks. Common examples include hammers, screwdrivers, wrenches, and pliers, each designed for specific functions such as gripping, turning, or hammering. These tools offer portability, simplicity, and control, essential for detailed craftsmanship and basic maintenance activities.

Understanding Power Tools: Types and Uses

Power tools encompass a diverse range of equipment designed for tasks requiring speed, precision, and efficiency, including drills, saws, grinders, and sanders. Each type serves specific functions, such as cordless drills ideal for drilling and fastening, circular saws for cutting wood or metal, and angle grinders for grinding or polishing surfaces. Understanding the appropriate power tool for a given application enhances productivity and ensures safety during construction, woodworking, and repair projects.

Key Differences Between Hand Tools and Power Tools

Hand tools operate manually, relying solely on physical effort, while power tools use electric, battery, or pneumatic energy to perform tasks more efficiently. Hand tools provide greater precision and control, making them ideal for delicate work, whereas power tools excel in speed and power, suitable for heavy-duty applications. Selecting between hand tools and power tools depends on the specific project requirements, desired efficiency, and user skill level.

Advantages of Using Hand Tools

Hand tools offer superior precision and control, making them ideal for detailed craftsmanship and delicate tasks. They require no power source, ensuring portability and reducing operational costs. Their simplicity and durability result in lower maintenance and longer lifespan compared to power tools.

Benefits of Using Power Tools

Power tools significantly increase efficiency by delivering consistent power and precision, reducing physical effort and task completion time. Their advanced motor technology allows for handling tougher materials and performing more complex tasks with ease compared to hand tools. Enhanced ergonomics and versatility further improve user comfort and expand the range of applications, making power tools indispensable in professional and DIY projects.

Safety Considerations: Hand Tools vs Power Tools

Hand tools generally pose lower injury risks due to their manual operation and limited force, making them safer for precise tasks and beginners. Power tools, while more efficient, require stringent safety measures such as protective gear, proper training, and adherence to manufacturer guidelines to prevent accidents caused by high-speed components and electrical hazards. Choosing between hand and power tools should involve evaluating task complexity, operator skill, and the potential for injury to ensure optimal safety.

Cost Comparison: Hand Tools vs Power Tools

Hand tools generally have a lower initial cost compared to power tools, making them accessible for basic tasks and budget-conscious users. Power tools, while more expensive upfront, often provide greater efficiency and faster completion times, which can offset the higher purchase price in professional or frequent use contexts. Considering long-term value, power tools may require additional expenses for maintenance, batteries, or electricity, whereas hand tools have minimal ongoing costs.

Ideal Applications for Hand Tools and Power Tools

Hand tools excel in precision tasks and delicate work such as woodworking, fine metalworking, and electrical installation due to their control and portability. Power tools are ideal for heavy-duty applications like construction, demolition, and large-scale fabrication where speed and efficiency are critical. Selecting between hand and power tools depends on the project size, required accuracy, and operator skill level.

Choosing the Right Tool for Your Project

Choosing the right tool for your project depends on the task's complexity, precision requirements, and available power sources. Hand tools offer greater control and are ideal for detailed, low-intensity work, while power tools deliver efficiency and speed for larger-scale or repetitive tasks. Assessing factors such as material type, project duration, and user skill level helps determine whether a hand tool or power tool will optimize performance and safety.

Hand Tool vs Power Tool Infographic

productdif.com

productdif.com