Optical sorting uses advanced sensors and cameras to quickly and accurately separate materials based on color, size, and shape, significantly increasing efficiency compared to manual sorting. This technology minimizes human error, reduces labor costs, and enhances product quality consistency. Manual sorting remains labor-intensive, slower, and prone to inconsistencies, making it less suitable for high-volume or precision-required operations.

Table of Comparison

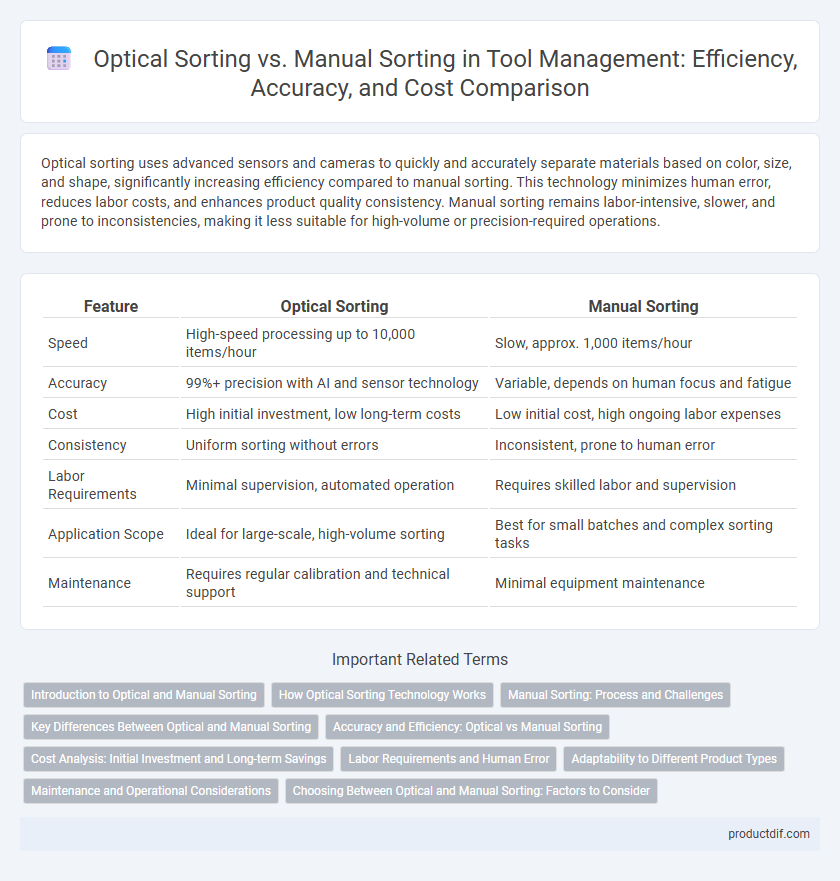

| Feature | Optical Sorting | Manual Sorting |

|---|---|---|

| Speed | High-speed processing up to 10,000 items/hour | Slow, approx. 1,000 items/hour |

| Accuracy | 99%+ precision with AI and sensor technology | Variable, depends on human focus and fatigue |

| Cost | High initial investment, low long-term costs | Low initial cost, high ongoing labor expenses |

| Consistency | Uniform sorting without errors | Inconsistent, prone to human error |

| Labor Requirements | Minimal supervision, automated operation | Requires skilled labor and supervision |

| Application Scope | Ideal for large-scale, high-volume sorting | Best for small batches and complex sorting tasks |

| Maintenance | Requires regular calibration and technical support | Minimal equipment maintenance |

Introduction to Optical and Manual Sorting

Optical sorting utilizes advanced sensors and cameras to identify and separate materials based on color, shape, and size, enhancing accuracy and throughput in processing. Manual sorting relies on human visual inspection and physical handling, which can be slower and less consistent but useful for complex or delicate items. Both methods serve critical roles in industries such as recycling, food production, and mining, where efficiency and precision are paramount.

How Optical Sorting Technology Works

Optical sorting technology utilizes advanced sensors and cameras to detect and analyze the color, shape, size, and composition of materials on a conveyor belt, enabling precise separation of desired items from contaminants. High-speed processors interpret visual data in real time to trigger air jets or mechanical arms that sort objects with exceptional accuracy, significantly reducing human error. This automated process enhances efficiency in industries such as agriculture, recycling, and manufacturing, where consistent quality control and throughput are critical.

Manual Sorting: Process and Challenges

Manual sorting involves the physical inspection and separation of items based on visual cues such as color, size, or texture, relying heavily on human judgment and dexterity. This process faces challenges including human fatigue, inconsistent accuracy, and slower throughput compared to automated methods. Despite these limitations, manual sorting remains essential for handling irregular or delicate materials that optical sorting technology cannot easily analyze.

Key Differences Between Optical and Manual Sorting

Optical sorting uses advanced sensors and imaging technology to identify and separate items based on color, size, shape, and composition, providing higher precision and speed compared to manual sorting. Manual sorting relies on human inspection, which can lead to inconsistencies and slower processing times due to fatigue and subjective judgment. Optical sorting enhances efficiency and accuracy in industries like recycling and food processing, reducing labor costs and minimizing sorting errors.

Accuracy and Efficiency: Optical vs Manual Sorting

Optical sorting achieves accuracy rates exceeding 99% by utilizing advanced sensors and machine learning algorithms to detect and separate items based on color, size, and shape, significantly reducing human error. Manual sorting, while flexible for complex or irregular items, typically maintains lower accuracy rates around 85-90% due to fatigue and subjective judgment. Efficiency in optical sorting surpasses manual methods, processing thousands of items per minute with consistent quality, whereas manual sorting is slower and more labor-intensive, limiting throughput and increasing operational costs.

Cost Analysis: Initial Investment and Long-term Savings

Optical sorting systems require a higher initial investment compared to manual sorting due to advanced sensor technology and automation equipment. Long-term savings are significant as optical sorting reduces labor costs, increases processing speed, and improves accuracy, minimizing material waste and reprocessing expenses. Manual sorting involves lower upfront costs but leads to higher ongoing labor expenses and inconsistent quality control, impacting overall operational efficiency.

Labor Requirements and Human Error

Optical sorting technology significantly reduces labor requirements by automating the identification and separation of materials, enabling faster and more consistent processing compared to manual sorting. This automation minimizes human error, which is common in manual sorting due to fatigue, inconsistent judgment, and variability in attention. Enhanced accuracy and reduced operational costs make optical sorting a preferred solution for industries aiming to optimize productivity and quality control.

Adaptability to Different Product Types

Optical sorting technology offers superior adaptability across diverse product types by utilizing advanced sensors and machine learning algorithms that can identify and separate items based on color, size, shape, and material properties. Manual sorting relies heavily on human skill and experience, which can lead to variability and reduced efficiency when handling heterogeneous batches or intricate quality criteria. Farms and factories increasingly prefer optical sorting due to its precision, consistency, and ability to quickly switch between different product sorting configurations.

Maintenance and Operational Considerations

Optical sorting systems require regular calibration and sensor cleaning to maintain accuracy, while manual sorting demands consistent workforce training to reduce human error. Maintenance of optical tools involves specialized technical support and software updates, contrasting with manual methods that rely on ergonomic adjustments and employee well-being. Operational efficiency improves with optical sorting due to faster processing speeds and less downtime, whereas manual sorting's operational challenges include variability in labor performance and higher fatigue rates.

Choosing Between Optical and Manual Sorting: Factors to Consider

Choosing between optical and manual sorting depends on factors such as speed, accuracy, and cost-efficiency. Optical sorting technology offers high-speed processing and precise detection of defects, reducing labor costs and minimizing human error. Manual sorting remains preferable for small-scale operations or when handling complex, irregular items that require human judgment.

Optical Sorting vs Manual Sorting Infographic

productdif.com

productdif.com