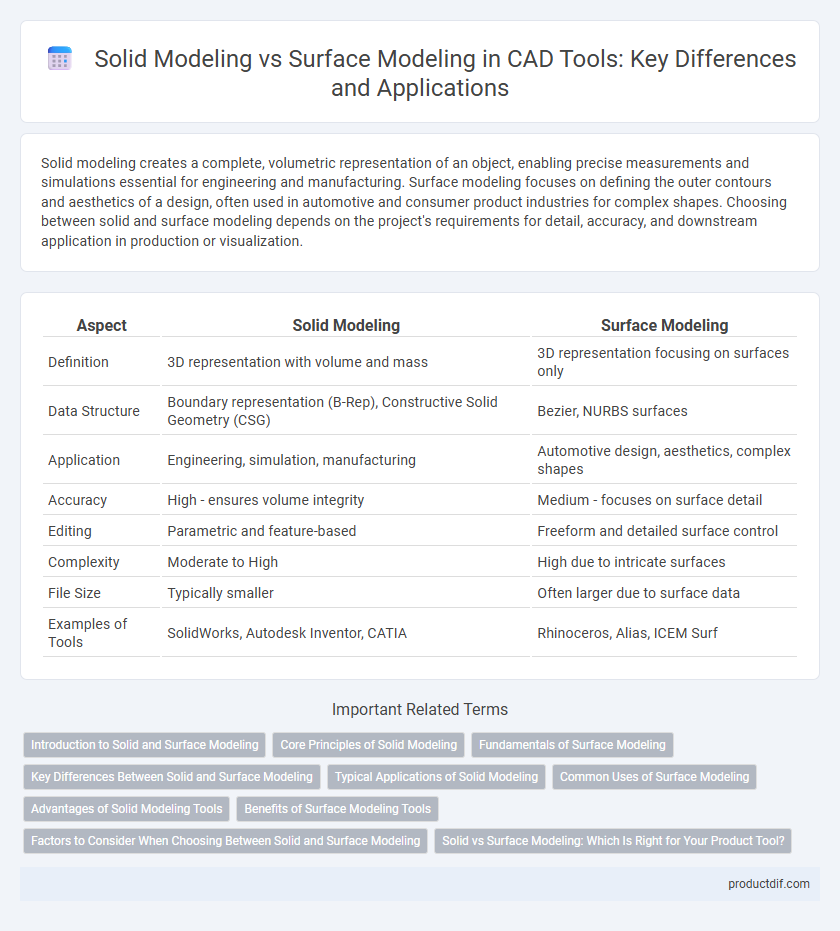

Solid modeling creates a complete, volumetric representation of an object, enabling precise measurements and simulations essential for engineering and manufacturing. Surface modeling focuses on defining the outer contours and aesthetics of a design, often used in automotive and consumer product industries for complex shapes. Choosing between solid and surface modeling depends on the project's requirements for detail, accuracy, and downstream application in production or visualization.

Table of Comparison

| Aspect | Solid Modeling | Surface Modeling |

|---|---|---|

| Definition | 3D representation with volume and mass | 3D representation focusing on surfaces only |

| Data Structure | Boundary representation (B-Rep), Constructive Solid Geometry (CSG) | Bezier, NURBS surfaces |

| Application | Engineering, simulation, manufacturing | Automotive design, aesthetics, complex shapes |

| Accuracy | High - ensures volume integrity | Medium - focuses on surface detail |

| Editing | Parametric and feature-based | Freeform and detailed surface control |

| Complexity | Moderate to High | High due to intricate surfaces |

| File Size | Typically smaller | Often larger due to surface data |

| Examples of Tools | SolidWorks, Autodesk Inventor, CATIA | Rhinoceros, Alias, ICEM Surf |

Introduction to Solid and Surface Modeling

Solid modeling represents objects with complete volume and mass properties, enabling precise simulations and engineering analyses, while surface modeling defines only object boundaries without thickness, ideal for complex shapes and aesthetic designs. Solid models maintain data on an object's interior and exterior, supporting functions like mass property calculations and interference checking; surface models focus on detailed external geometry without volume information. Understanding the differences assists designers in selecting appropriate CAD tools for manufacturing precision or visual presentation.

Core Principles of Solid Modeling

Solid modeling relies on defining the volume and mass of an object through mathematical representations like boundary representation (B-rep) and constructive solid geometry (CSG), ensuring complete spatial information. It emphasizes the integrity of 3D objects as solids with precise physical properties such as mass, density, and center of gravity, which are essential for accurate simulations and manufacturing processes. Core principles include boolean operations, feature-based modeling, and parametric control, enabling robust and editable 3D models for engineering and CAD applications.

Fundamentals of Surface Modeling

Surface modeling fundamentally involves creating and manipulating surfaces to represent complex shapes that are difficult to achieve with solid modeling's volumetric approach. It excels in industries like automotive and aerospace design, where fine detail and smooth contours are essential. Techniques such as NURBS and Bezier curves enable precise control over surface curvature, offering superior flexibility compared to traditional solid modeling methods.

Key Differences Between Solid and Surface Modeling

Solid modeling represents objects with complete volume and mass, enabling precise engineering analysis and manufacturing processes. Surface modeling defines only the object's external boundaries without volume, making it ideal for complex shape design and aesthetic visualization. Key differences include solid modeling's focus on physical properties and integrity, whereas surface modeling emphasizes detailed surface geometry and flexibility in adjustments.

Typical Applications of Solid Modeling

Solid modeling is widely used in mechanical engineering for designing complex parts and assemblies, offering precise volume and mass properties essential for simulations and manufacturing processes. It is typical in industries such as aerospace, automotive, and industrial equipment, where durability and exact dimensions are critical. Solid models enable efficient CAD/CAM integration, supporting tooling design and CNC machining workflows.

Common Uses of Surface Modeling

Surface modeling is commonly used in automotive design for creating complex, smooth exterior shapes and intricate curves that define a vehicle's aesthetic appeal. It excels in industries such as aerospace and consumer electronics where detailed, visually accurate representations of surfaces are critical for aerodynamic performance and ergonomic design. This technique is preferred for conceptual modeling and prototyping, enabling designers to manipulate surfaces without the constraints of volume solids.

Advantages of Solid Modeling Tools

Solid modeling tools offer precise volume and mass calculations essential for engineering analysis and manufacturing processes. These tools enable full 3D representation with robust data integrity, allowing for easier modifications and assembly simulations. Designers benefit from improved error detection and compatibility with computer-aided manufacturing (CAM) systems, streamlining production workflows.

Benefits of Surface Modeling Tools

Surface modeling tools offer superior flexibility for creating complex, organic shapes and intricate details that are challenging to achieve with solid modeling. These tools enable precise control over individual surfaces, facilitating smooth and visually appealing designs ideal for automotive, aerospace, and consumer product industries. Enhanced surface manipulation capabilities reduce design time and improve aesthetic accuracy by allowing for seamless adjustments and refinements.

Factors to Consider When Choosing Between Solid and Surface Modeling

When choosing between solid and surface modeling, factors such as the complexity of the geometry, the required precision, and the end-use application must be considered. Solid modeling is ideal for mechanical parts that demand accurate volume and mass properties, while surface modeling excels in creating intricate, free-form shapes for automotive and aerospace design. Software compatibility, simulation needs, and manufacturing processes also play crucial roles in selecting the appropriate modeling technique.

Solid vs Surface Modeling: Which Is Right for Your Product Tool?

Solid modeling provides a comprehensive 3D representation by defining volume and mass, making it ideal for engineering, manufacturing, and simulation where structure and functionality are critical. Surface modeling emphasizes the creation of complex, detailed surfaces and is preferred for aesthetic design, automotive, and consumer product industries where visual appearance and smooth contours are essential. Choosing between solid and surface modeling depends on whether your product tool prioritizes structural integrity and mechanical analysis or precise surface detail and visual refinement.

Solid modeling vs Surface modeling Infographic

productdif.com

productdif.com