Additive manufacturing builds objects layer by layer from raw materials, enabling complex geometries and minimal material waste. Subtractive manufacturing removes material through cutting, drilling, or milling, offering high precision and surface finish for simpler designs. Each method serves distinct applications based on design complexity, production volume, and material properties.

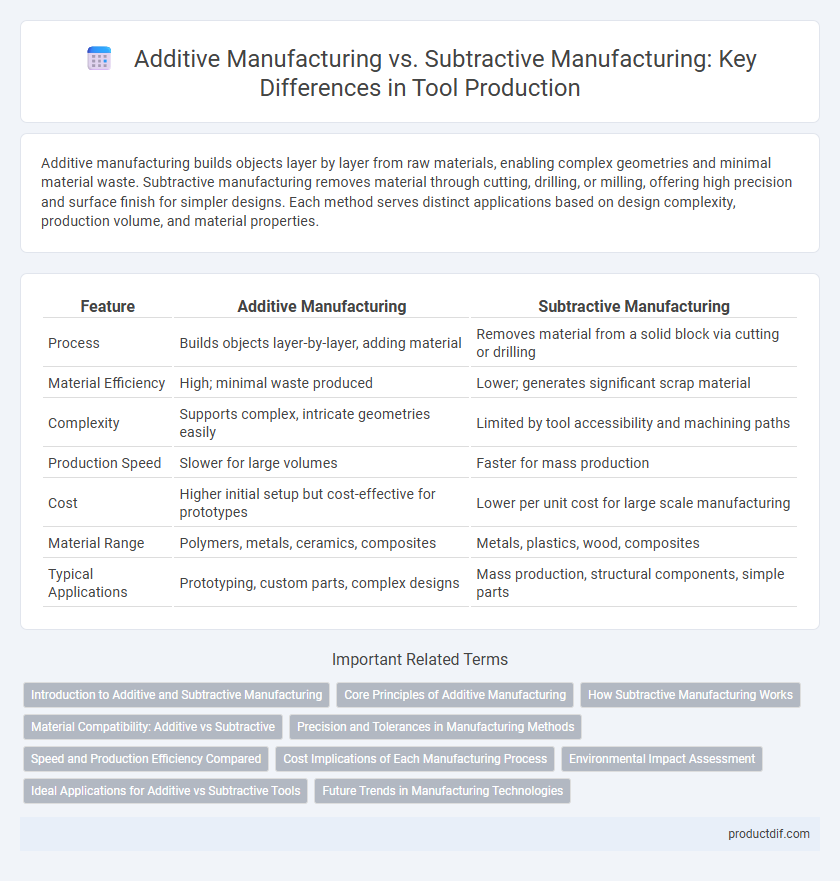

Table of Comparison

| Feature | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Process | Builds objects layer-by-layer, adding material | Removes material from a solid block via cutting or drilling |

| Material Efficiency | High; minimal waste produced | Lower; generates significant scrap material |

| Complexity | Supports complex, intricate geometries easily | Limited by tool accessibility and machining paths |

| Production Speed | Slower for large volumes | Faster for mass production |

| Cost | Higher initial setup but cost-effective for prototypes | Lower per unit cost for large scale manufacturing |

| Material Range | Polymers, metals, ceramics, composites | Metals, plastics, wood, composites |

| Typical Applications | Prototyping, custom parts, complex designs | Mass production, structural components, simple parts |

Introduction to Additive and Subtractive Manufacturing

Additive manufacturing builds objects layer by layer from digital models using materials such as plastics, metals, or composites, enabling complex geometries and material efficiency. Subtractive manufacturing removes material from solid blocks through cutting, drilling, or milling, providing high precision and surface finish for components. Both methods serve critical roles in prototyping, production, and customization across aerospace, automotive, and medical industries.

Core Principles of Additive Manufacturing

Additive manufacturing builds objects layer by layer directly from digital models using materials like plastics, metals, or composites, enabling complex geometries and reduced waste. Core principles include material deposition, precise control of energy sources such as lasers or electron beams, and digital design flexibility for rapid prototyping and production. This process contrasts with subtractive manufacturing, which removes material through milling or cutting, often resulting in more waste and design constraints.

How Subtractive Manufacturing Works

Subtractive manufacturing operates by removing material from a solid block through cutting, drilling, or milling processes to create precise parts. It relies heavily on Computer Numerical Control (CNC) machines that guide cutting tools along predefined paths for accuracy and repeatability. This method is preferred for producing components from metals, plastics, and composites where tight tolerances and smooth surface finishes are required.

Material Compatibility: Additive vs Subtractive

Additive manufacturing excels in working with a broad range of materials, including polymers, metals, ceramics, and composites, allowing complex geometries and customized material properties. Subtractive manufacturing is typically limited to materials that can be machined effectively, such as metals, plastics, and wood, but struggles with brittle or highly complex composite materials. Material compatibility in additive processes offers increased design freedom and less material waste compared to the constraints and higher material rejection rates often seen in subtractive manufacturing.

Precision and Tolerances in Manufacturing Methods

Additive manufacturing offers superior precision by building components layer by layer, enabling complex geometries with tight tolerances often within microns. Subtractive manufacturing achieves high accuracy by removing material from a solid block, typically maintaining tolerances around +-0.01 mm depending on the tooling and machinery. Advanced CNC machining in subtractive methods can outperform additive processes in surface finish quality but may struggle with intricate internal structures achievable through additive techniques.

Speed and Production Efficiency Compared

Additive manufacturing enables faster prototyping and complex geometries with minimal material waste, significantly improving production efficiency for customized or small-batch parts. Subtractive manufacturing excels in high-volume production with consistent precision and shorter cycle times on standardized components, leveraging established machining processes and optimized tool paths. Speed advantages depend on project scale and complexity, where additive methods reduce setup time, while subtractive offers rapid material removal for large quantities.

Cost Implications of Each Manufacturing Process

Additive manufacturing reduces material waste and lowers initial tooling costs, making it cost-effective for low-volume production and complex designs. Subtractive manufacturing often incurs higher material loss and tooling expenses but delivers faster production speeds and cost advantages in high-volume runs. Understanding these cost implications helps manufacturers choose the optimal process based on project scale and design complexity.

Environmental Impact Assessment

Additive manufacturing reduces material waste by building components layer-by-layer, significantly lowering raw material consumption compared to subtractive manufacturing, which involves cutting away excess material from a solid block. Energy consumption in additive processes can be more efficient due to minimized machining and tooling requirements, contributing to a smaller carbon footprint. Life cycle assessments highlight that additive manufacturing generates less hazardous waste and enables designs that optimize resource use, making it a more sustainable choice in eco-conscious production environments.

Ideal Applications for Additive vs Subtractive Tools

Additive manufacturing is ideal for producing complex geometries, customized parts, and low-volume production runs, particularly in aerospace, medical implants, and prototyping industries. Subtractive manufacturing excels in creating high-precision, durable components from solid materials, making it suitable for mass production and applications requiring tight tolerances such as automotive parts and metal tooling. Each process serves distinct needs based on design complexity, production volume, and material type, optimizing tool efficiency and cost-effectiveness.

Future Trends in Manufacturing Technologies

Additive manufacturing is rapidly advancing with innovations like multi-material 3D printing and enhanced automation, enabling complex designs and reduced material waste. Subtractive manufacturing continues to evolve through precision machining and AI-driven process optimization, increasing accuracy and efficiency in mass production. Future trends emphasize hybrid manufacturing systems that integrate additive and subtractive techniques for superior customization and scalability in industrial applications.

Additive Manufacturing vs Subtractive Manufacturing Infographic

productdif.com

productdif.com