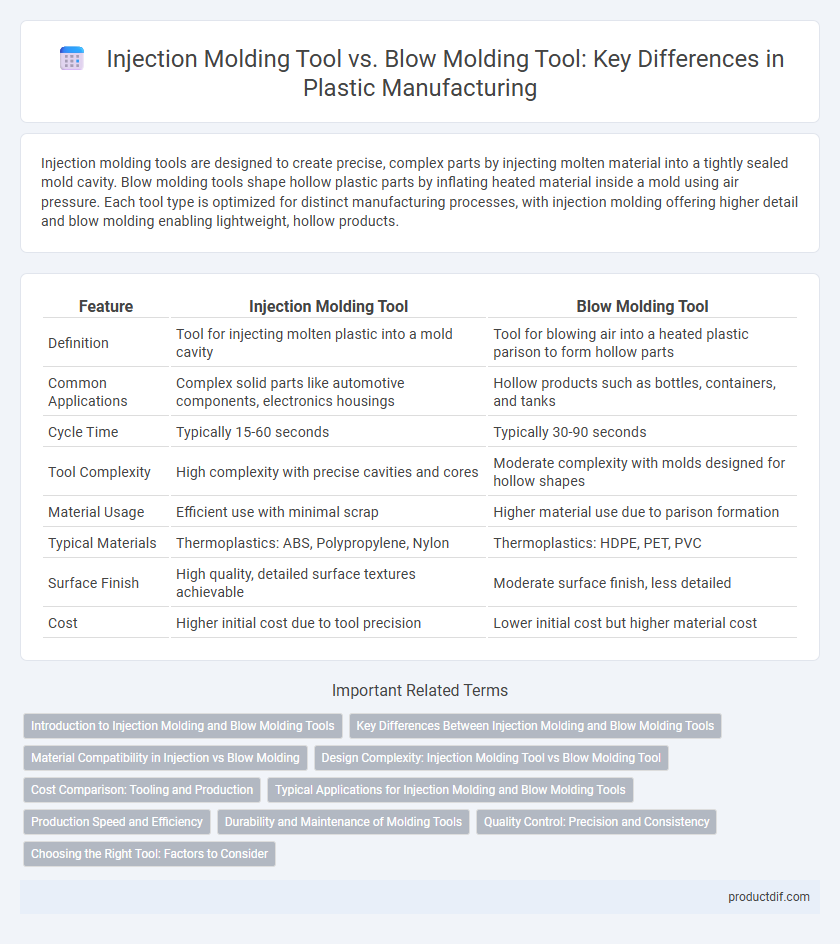

Injection molding tools are designed to create precise, complex parts by injecting molten material into a tightly sealed mold cavity. Blow molding tools shape hollow plastic parts by inflating heated material inside a mold using air pressure. Each tool type is optimized for distinct manufacturing processes, with injection molding offering higher detail and blow molding enabling lightweight, hollow products.

Table of Comparison

| Feature | Injection Molding Tool | Blow Molding Tool |

|---|---|---|

| Definition | Tool for injecting molten plastic into a mold cavity | Tool for blowing air into a heated plastic parison to form hollow parts |

| Common Applications | Complex solid parts like automotive components, electronics housings | Hollow products such as bottles, containers, and tanks |

| Cycle Time | Typically 15-60 seconds | Typically 30-90 seconds |

| Tool Complexity | High complexity with precise cavities and cores | Moderate complexity with molds designed for hollow shapes |

| Material Usage | Efficient use with minimal scrap | Higher material use due to parison formation |

| Typical Materials | Thermoplastics: ABS, Polypropylene, Nylon | Thermoplastics: HDPE, PET, PVC |

| Surface Finish | High quality, detailed surface textures achievable | Moderate surface finish, less detailed |

| Cost | Higher initial cost due to tool precision | Lower initial cost but higher material cost |

Introduction to Injection Molding and Blow Molding Tools

Injection molding tools are precision-engineered molds designed to inject molten plastic into complex cavities for high-volume production of detailed parts with tight tolerances. Blow molding tools, by contrast, shape hollow plastic products by inflating heated plastic inside a mold, ideal for creating uniform, lightweight containers like bottles. Both tools are fundamental in plastic manufacturing, with injection molding excelling in solid part creation and blow molding specialized for hollow, thin-walled objects.

Key Differences Between Injection Molding and Blow Molding Tools

Injection molding tools consist of precisely machined steel molds designed for high-pressure injection of molten plastic, enabling the creation of complex, detailed parts with tight tolerances. Blow molding tools feature hollow molds that shape molten plastic by inflating it with compressed air, ideal for producing hollow objects like bottles and containers. Key differences include the tooling design complexity, with injection molds being more intricate for detailed features, while blow molds prioritize uniform thickness and hollow shapes.

Material Compatibility in Injection vs Blow Molding

Injection molding tools are designed to accommodate a wider range of thermoplastic materials, including high-performance polymers like polycarbonate and nylon, which require precise temperature control and pressure during molding. Blow molding tools are primarily optimized for processing flexible, low-viscosity materials such as polyethylene and polypropylene, which are suited for hollow containers and lightweight applications. The fundamental difference in material compatibility arises from the distinct processing methods, where injection molding demands materials with higher shear resistance, and blow molding relies on materials that can be easily inflated and stretched without rupture.

Design Complexity: Injection Molding Tool vs Blow Molding Tool

Injection molding tools feature intricate cavities and core pins designed to produce precise, complex geometries with tight tolerances, making their design and fabrication highly detailed and time-consuming. Blow molding tools, in contrast, emphasize hollow part creation with simpler two-part molds and fewer moving components, resulting in lower design complexity. The advanced engineering required for injection molds demands sophisticated temperature control and venting systems, whereas blow molding tools focus more on parison formation and inflation mechanisms.

Cost Comparison: Tooling and Production

Injection molding tools typically incur higher initial tooling costs due to more complex mold designs and tighter tolerances, often ranging from $10,000 to $500,000 depending on part complexity. Blow molding tools generally have lower tooling expenses, approximately $5,000 to $150,000, as their molds are simpler and less precise. Production costs for injection molding are higher per cycle because of longer cycle times and greater material usage, while blow molding offers lower cycle costs suitable for hollow parts but may require more maintenance over time.

Typical Applications for Injection Molding and Blow Molding Tools

Injection molding tools are typically used for manufacturing precise, complex components such as automotive parts, electronics housings, and medical devices due to their ability to produce detailed shapes with tight tolerances. Blow molding tools are commonly employed for creating hollow plastic products like bottles, containers, and large storage tanks, where uniform wall thickness and lightweight designs are essential. Both tools cater to high-volume production but differ in the types of plastic parts they efficiently produce.

Production Speed and Efficiency

Injection molding tools typically offer faster production speeds due to their ability to produce complex parts with high precision in a single cycle, often completing a cycle in seconds. Blow molding tools, while efficient for hollow parts like bottles, generally have longer cycle times and lower overall production speed compared to injection molding. The efficiency of injection molding tools is enhanced by automation and reduced post-processing, making them ideal for high-volume manufacturing.

Durability and Maintenance of Molding Tools

Injection molding tools typically exhibit higher durability due to their robust steel construction, designed to withstand high pressures and temperatures during the molding process. Blow molding tools, often made from aluminum or softer metals, require more frequent maintenance to address wear and potential deformation caused by cyclical air pressure. Regular inspection and timely replacement of components are essential for maintaining the longevity of both tool types, but injection molding tools generally demand less frequent and less intensive maintenance.

Quality Control: Precision and Consistency

Injection molding tools deliver superior precision and consistency in producing complex, detailed parts due to their tightly controlled molten plastic flow and high-pressure application. Blow molding tools, while effective for hollow objects, typically face greater challenges in maintaining uniform wall thickness and dimensional accuracy. Rigorous quality control in injection molding ensures minimal defects and tight tolerances, making it ideal for applications demanding high-quality, consistent components.

Choosing the Right Tool: Factors to Consider

Choosing the right tool between injection molding and blow molding depends on the product design, material type, and production volume. Injection molding tools are ideal for complex, high-precision parts made from thermoplastics, while blow molding tools are better suited for hollow, lightweight containers such as bottles. Cost considerations, cycle time, and part functionality also play crucial roles in determining the most efficient and effective molding process.

Injection Molding Tool vs Blow Molding Tool Infographic

productdif.com

productdif.com