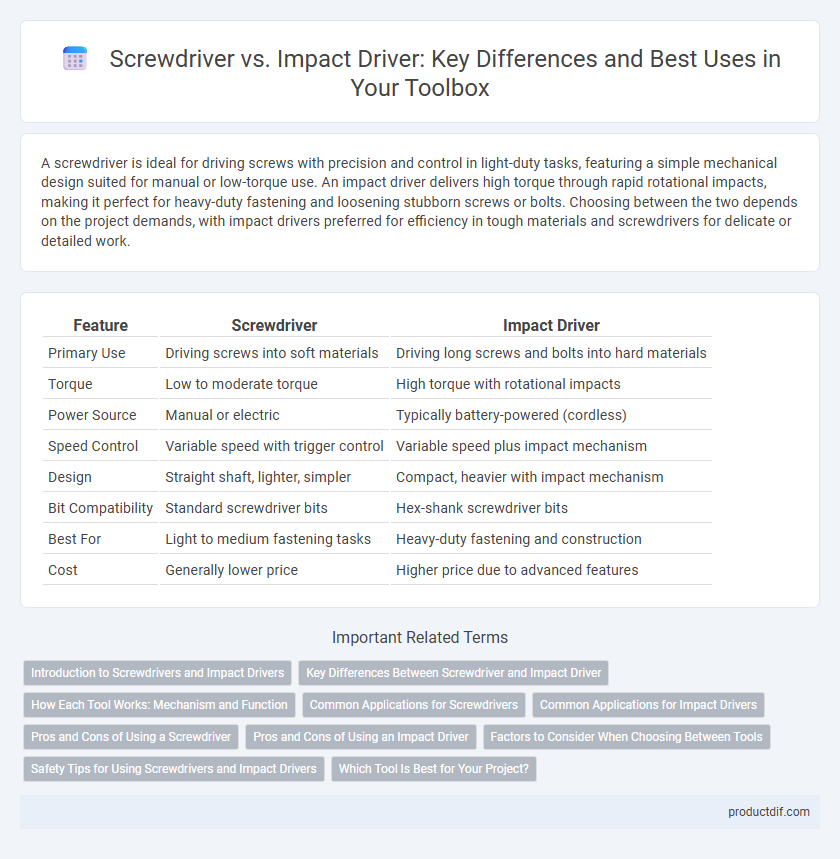

A screwdriver is ideal for driving screws with precision and control in light-duty tasks, featuring a simple mechanical design suited for manual or low-torque use. An impact driver delivers high torque through rapid rotational impacts, making it perfect for heavy-duty fastening and loosening stubborn screws or bolts. Choosing between the two depends on the project demands, with impact drivers preferred for efficiency in tough materials and screwdrivers for delicate or detailed work.

Table of Comparison

| Feature | Screwdriver | Impact Driver |

|---|---|---|

| Primary Use | Driving screws into soft materials | Driving long screws and bolts into hard materials |

| Torque | Low to moderate torque | High torque with rotational impacts |

| Power Source | Manual or electric | Typically battery-powered (cordless) |

| Speed Control | Variable speed with trigger control | Variable speed plus impact mechanism |

| Design | Straight shaft, lighter, simpler | Compact, heavier with impact mechanism |

| Bit Compatibility | Standard screwdriver bits | Hex-shank screwdriver bits |

| Best For | Light to medium fastening tasks | Heavy-duty fastening and construction |

| Cost | Generally lower price | Higher price due to advanced features |

Introduction to Screwdrivers and Impact Drivers

Screwdrivers and impact drivers are essential hand tools designed for driving screws, each serving distinct functions in construction and DIY projects. Screwdrivers provide precise control and torque for fastening screws, featuring various tip types like Phillips, flathead, and Torx to match different screw heads. Impact drivers deliver high rotational force and concussive blows, ideal for driving long or tough screws with greater efficiency and reduced user fatigue.

Key Differences Between Screwdriver and Impact Driver

A screwdriver delivers consistent torque for driving screws into softer materials, ideal for precision tasks, while an impact driver generates high rotational and concussive force suited for driving long or large fasteners into dense materials. Screwdrivers typically operate at lower speeds with higher control, whereas impact drivers provide rapid bursts of torque, reducing user fatigue and preventing stripping of screws. Impact drivers often feature hexagonal chucks compatible with various bits, contrasting with screwdrivers' traditional straight or Phillips bit compatibility.

How Each Tool Works: Mechanism and Function

A screwdriver operates using manual or electric torque to turn screws by applying rotational force directly to the screw head, making it ideal for precision tasks and lighter applications. An impact driver combines rotational force with concussive blows to deliver high torque output, effectively driving screws and bolts into tougher materials without stripping the fastener. The impact mechanism allows the tool to maintain high efficiency in loosening and fastening tasks, particularly in construction and automotive work.

Common Applications for Screwdrivers

Screwdrivers are commonly used for precision tasks like assembling furniture, tightening cabinet hinges, and installing light fixtures where controlled torque is essential. They are ideal for driving small screws into softer materials such as wood, plastic, or drywall without damaging the surface. Regular maintenance tasks, including electronics repair and small appliance adjustments, also frequently rely on manual or electric screwdrivers due to their accuracy and ease of use.

Common Applications for Impact Drivers

Impact drivers excel in fastening long screws and bolts into dense materials like hardwood and metal, making them ideal for heavy-duty construction and woodworking tasks. Their high torque output and concussive rotational force efficiently drive fasteners with minimal user effort, especially in automotive repairs and outdoor projects. Common applications include deck building, framing, and assembling machinery where precision and power are critical.

Pros and Cons of Using a Screwdriver

A screwdriver offers precise control and is ideal for light-duty tasks such as assembling furniture or tightening small screws, providing ease of use and affordability. However, it lacks the torque power needed for driving large screws or working with dense materials, which can lead to hand fatigue during extended use. Its simplicity and lightweight design make it a practical choice for detailed work but limit its effectiveness in heavy-duty applications.

Pros and Cons of Using an Impact Driver

Impact drivers deliver high torque, making them ideal for driving long screws and bolts into tough materials, which reduces user fatigue and speeds up heavy-duty tasks. Their compact design and variable speed control allow for better maneuverability in tight spaces but can cause stripping or overdriving fasteners if not carefully controlled. Unlike traditional screwdrivers, impact drivers require specific bits, which can increase tool costs and maintenance needs.

Factors to Consider When Choosing Between Tools

Selecting between a screwdriver and an impact driver depends on torque requirements, with impact drivers providing higher torque for heavy-duty fastening. Consider the types of fasteners, as impact drivers excel with long screws and bolts, while screwdrivers suit light tasks and precision work. Battery life and ergonomic design also influence tool choice, especially for extended use or repetitive tasks.

Safety Tips for Using Screwdrivers and Impact Drivers

Wear safety glasses and gloves when using screwdrivers or impact drivers to protect against flying debris and accidental slips. Ensure the screwdriver or impact driver bit fits securely in the fastener to prevent stripping and reduce the risk of injury. Use the appropriate tool for the task: screwdrivers for precise, low-torque fastening and impact drivers for high-torque applications, minimizing the chance of tool damage and user strain.

Which Tool Is Best for Your Project?

Choosing between a screwdriver and an impact driver depends on the project's requirements for torque and precision. Screwdrivers excel in tasks needing controlled rotational force and delicate fastening, while impact drivers deliver higher torque ideal for driving large screws and bolts into tough materials. For heavy-duty construction or automotive projects, an impact driver offers superior performance, but for light assembly or electronics work, a screwdriver ensures accuracy without damaging fasteners.

Screwdriver vs Impact Driver Infographic

productdif.com

productdif.com