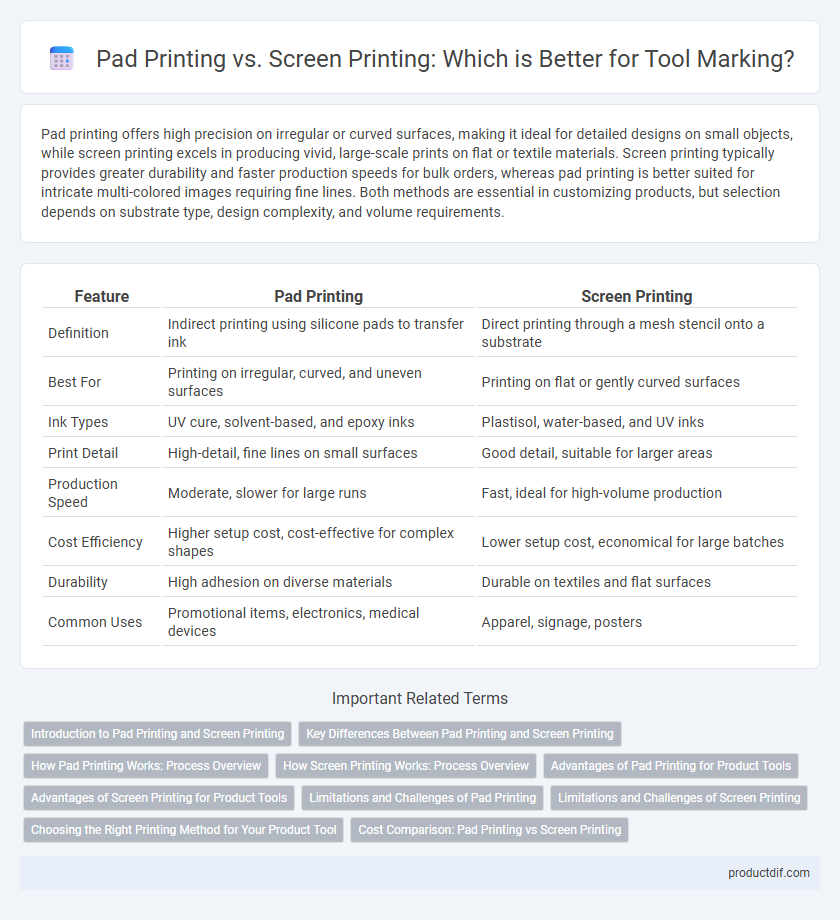

Pad printing offers high precision on irregular or curved surfaces, making it ideal for detailed designs on small objects, while screen printing excels in producing vivid, large-scale prints on flat or textile materials. Screen printing typically provides greater durability and faster production speeds for bulk orders, whereas pad printing is better suited for intricate multi-colored images requiring fine lines. Both methods are essential in customizing products, but selection depends on substrate type, design complexity, and volume requirements.

Table of Comparison

| Feature | Pad Printing | Screen Printing |

|---|---|---|

| Definition | Indirect printing using silicone pads to transfer ink | Direct printing through a mesh stencil onto a substrate |

| Best For | Printing on irregular, curved, and uneven surfaces | Printing on flat or gently curved surfaces |

| Ink Types | UV cure, solvent-based, and epoxy inks | Plastisol, water-based, and UV inks |

| Print Detail | High-detail, fine lines on small surfaces | Good detail, suitable for larger areas |

| Production Speed | Moderate, slower for large runs | Fast, ideal for high-volume production |

| Cost Efficiency | Higher setup cost, cost-effective for complex shapes | Lower setup cost, economical for large batches |

| Durability | High adhesion on diverse materials | Durable on textiles and flat surfaces |

| Common Uses | Promotional items, electronics, medical devices | Apparel, signage, posters |

Introduction to Pad Printing and Screen Printing

Pad printing uses a silicone pad to transfer ink onto irregular or curved surfaces, enabling precise and detailed prints on products like electronics, medical devices, and promotional items. Screen printing involves pushing ink through a mesh stencil onto flat or slightly textured surfaces, ideal for textiles, posters, and signage with vibrant, durable colors. Both techniques cater to different material types and print complexities, making them essential in manufacturing and branding.

Key Differences Between Pad Printing and Screen Printing

Pad printing uses a silicone pad to transfer ink onto irregular or curved surfaces, enabling high-detail and multi-color designs on complex shapes. Screen printing involves pushing ink through a mesh stencil onto flat or slightly textured surfaces, ideal for large, consistent prints on materials like fabric, glass, or metal. Key differences include pad printing's superior ability to print on uneven surfaces versus screen printing's efficiency for high-volume runs on flat substrates.

How Pad Printing Works: Process Overview

Pad printing utilizes a silicone pad to transfer ink from an etched plate onto a target surface, allowing for precise application on irregular or curved objects. The process begins with the creation of an etched image on a printing plate, followed by ink being spread over this plate, where excess ink is removed by a doctor blade. The silicone pad then picks up the inked image and presses it onto the substrate, achieving detailed and consistent prints on complex shapes.

How Screen Printing Works: Process Overview

Screen printing works by using a mesh screen stretched tightly over a frame, where specific areas are blocked off with a stencil to create the design. Ink is then forced through the mesh openings onto the printing surface using a squeegee, allowing precise application of multiple layers and colors. This process is ideal for printing on various materials including textiles, plastics, and metals, offering durability and vibrant results.

Advantages of Pad Printing for Product Tools

Pad printing offers superior precision and versatility for decorating complex and irregular surfaces on product tools compared to screen printing. It enables high-quality, detailed images on three-dimensional shapes, making it ideal for intricate designs and small components. The process accommodates various inks and substrates, enhancing durability and color vibrancy on diverse tool materials.

Advantages of Screen Printing for Product Tools

Screen printing offers superior durability and vibrant color retention on product tools, making it ideal for long-lasting branding. This method accommodates thicker inks that provide excellent resistance to wear, chemicals, and abrasion. The precision and versatility in screen printing enable intricate designs and consistent quality across a variety of tool materials.

Limitations and Challenges of Pad Printing

Pad printing faces challenges such as limited color complexity and difficulty in achieving consistent ink thickness on uneven surfaces. The process struggles with high-volume production due to slower setup times and pad wear affecting image quality. Moreover, intricate designs with fine details may suffer from image distortion during pad transfer, limiting precision compared to screen printing.

Limitations and Challenges of Screen Printing

Screen printing faces limitations such as difficulty in reproducing fine details and gradients due to mesh size constraints, which impacts image resolution. It requires extensive setup time and costs, making it less efficient for short print runs or highly customized designs. Challenges also include ink waste and environmental concerns, as solvent-based inks and cleaning processes can be hazardous.

Choosing the Right Printing Method for Your Product Tool

Pad printing offers precise, durable image application on irregular or curved surfaces, making it ideal for detailed designs on small tools and promotional items. Screen printing excels with vibrant colors and cost-effective production on flat or simple shapes, suitable for larger surfaces and bulk orders. Evaluating the product's shape, design complexity, and quantity helps determine whether pad printing or screen printing is the best method for efficient, high-quality results.

Cost Comparison: Pad Printing vs Screen Printing

Pad printing generally incurs lower setup costs compared to screen printing, making it more cost-effective for small to medium production runs, especially when printing on irregular or small surfaces. Screen printing benefits from economies of scale with reduced per-unit costs in large volume orders, despite higher initial expenses for screens and setup. Businesses should evaluate production volume and print surface complexity to determine the most cost-efficient method between pad printing and screen printing.

Pad Printing vs Screen Printing Infographic

productdif.com

productdif.com