3D printing enables rapid prototyping with high precision and complex geometries, making it ideal for small batch production and design iterations. Vacuum casting, on the other hand, excels in producing high-quality, durable parts with excellent surface finishes, suitable for functional testing and low-volume manufacturing. Comparing these methods helps determine the best approach based on project timelines, material properties, and cost efficiency.

Table of Comparison

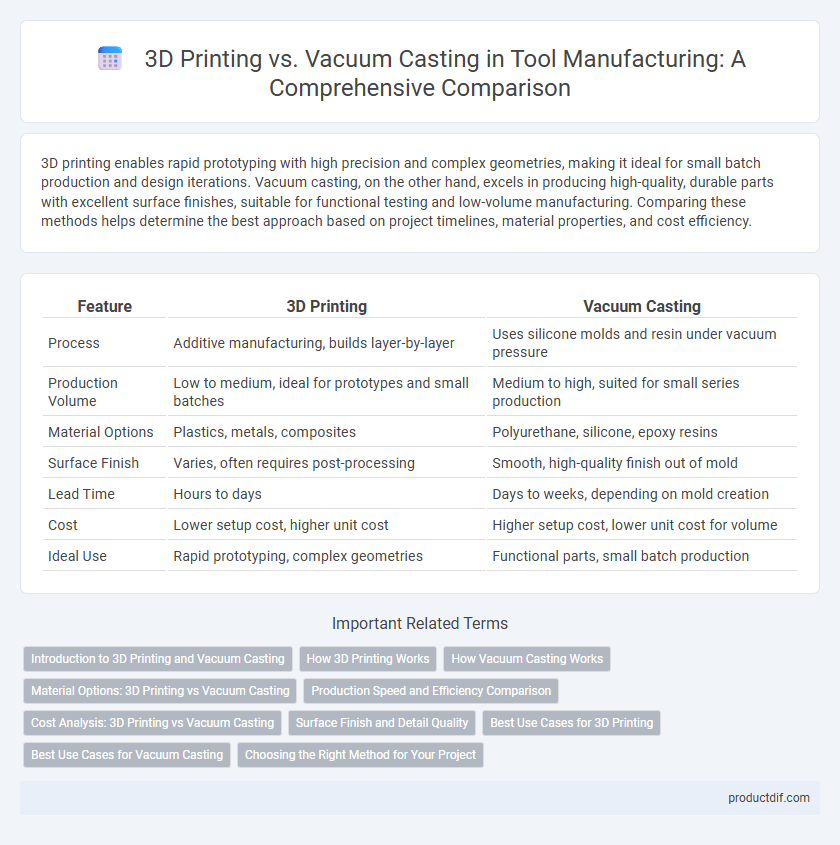

| Feature | 3D Printing | Vacuum Casting |

|---|---|---|

| Process | Additive manufacturing, builds layer-by-layer | Uses silicone molds and resin under vacuum pressure |

| Production Volume | Low to medium, ideal for prototypes and small batches | Medium to high, suited for small series production |

| Material Options | Plastics, metals, composites | Polyurethane, silicone, epoxy resins |

| Surface Finish | Varies, often requires post-processing | Smooth, high-quality finish out of mold |

| Lead Time | Hours to days | Days to weeks, depending on mold creation |

| Cost | Lower setup cost, higher unit cost | Higher setup cost, lower unit cost for volume |

| Ideal Use | Rapid prototyping, complex geometries | Functional parts, small batch production |

Introduction to 3D Printing and Vacuum Casting

3D printing is an additive manufacturing process that builds objects layer by layer from digital models, enabling rapid prototyping with high precision and complex geometries. Vacuum casting uses a silicone mold to reproduce parts from master patterns, ideal for small-batch production with detailed surface finishes and material properties similar to injection molding. Both techniques serve distinct purposes in product development, with 3D printing excelling in customization and speed, while vacuum casting offers cost-effective replication for functional testing.

How 3D Printing Works

3D printing builds objects layer by layer using digital models, employing materials like thermoplastics, resins, or metals fused through processes such as FDM, SLA, or SLS. It enables rapid prototyping and complex geometries by precisely depositing material guided by computer-aided design (CAD) files. This additive manufacturing approach contrasts with vacuum casting, which relies on molds and resin pouring for replication of parts.

How Vacuum Casting Works

Vacuum casting uses silicone molds created from a master prototype to produce high-fidelity replicas by pouring liquid resin into the mold under vacuum pressure, which removes air bubbles and ensures precise detail replication. This process allows for the production of smooth, durable parts with properties similar to injection-molded components, making it ideal for small batch manufacturing and prototyping. Compared to 3D printing, vacuum casting offers better surface finishes and material consistency, especially for complex geometries and functional testing.

Material Options: 3D Printing vs Vacuum Casting

3D printing offers a wide range of material options including plastics, resins, and metals, enabling complex geometries and rapid prototyping with customizable properties. Vacuum casting primarily uses polyurethane-based materials that closely mimic production-grade plastics, ideal for small batch runs with consistent mechanical and thermal characteristics. Material selection for 3D printing emphasizes versatility and speed, whereas vacuum casting focuses on replication quality and material performance akin to injection molding.

Production Speed and Efficiency Comparison

3D printing offers rapid prototyping with fast turnaround times ideal for low-volume production and complex geometries, significantly reducing initial setup and tooling costs. Vacuum casting excels in higher volume runs by producing multiple high-quality replicas quickly from silicone molds, delivering consistent part quality and better surface finishes. Production speed in 3D printing is limited by layer-by-layer fabrication, while vacuum casting efficiency increases substantially once molds are prepared, making it cost-effective for medium batch sizes.

Cost Analysis: 3D Printing vs Vacuum Casting

3D printing offers lower initial costs for small production runs due to minimal setup and tooling expenses, making it ideal for prototyping and custom parts. Vacuum casting requires higher upfront investment in mold creation, but provides cost efficiency at larger volumes through faster production cycles and repeatability. Evaluating cost-effectiveness depends on production quantity, with 3D printing favored for low volumes and vacuum casting preferred for medium to high-volume manufacturing.

Surface Finish and Detail Quality

3D printing offers high detail quality with precise layer resolution, making it ideal for intricate prototypes, but it often results in visible layer lines affecting surface finish. Vacuum casting excels in producing smooth surfaces with consistent textures ideal for final product aesthetics, while maintaining fine detail replication from the master pattern. Selecting between 3D printing and vacuum casting depends on prioritizing either detailed prototyping accuracy or superior surface finish for production-ready parts.

Best Use Cases for 3D Printing

3D printing excels in rapid prototyping, complex geometries, and low-volume production where customization and iteration speed are critical. It is ideal for creating intricate designs with fine details, enabling fast adjustments without the need for expensive tooling. This additive manufacturing method reduces material waste and is highly effective for functional testing and small batch manufacturing.

Best Use Cases for Vacuum Casting

Vacuum casting excels in producing high-quality prototypes and small batches of plastic parts with complex geometries and fine surface details, making it ideal for functional testing and presentation models. It is best suited for materials that require more durable, flexible, or heat-resistant properties compared to 3D printing, often used in automotive, aerospace, and medical device industries. This process offers cost-effective short-run manufacturing when injection molding is too expensive or time-consuming.

Choosing the Right Method for Your Project

3D printing offers rapid prototyping with high precision and is ideal for complex, low-volume parts requiring intricate details or customization. Vacuum casting excels in producing small-batch, high-quality replicas with materials that mimic final product properties, making it suitable for functional testing and short production runs. Selecting the right method depends on project goals, budget, desired material characteristics, and production volume, ensuring optimal performance and cost-efficiency.

3D Printing vs Vacuum Casting Infographic

productdif.com

productdif.com