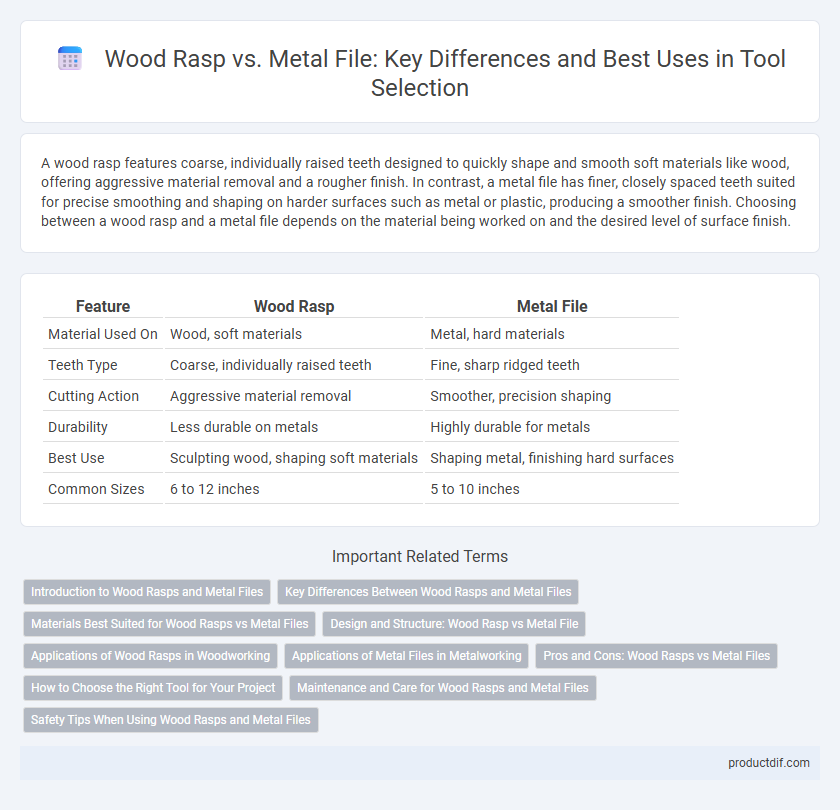

A wood rasp features coarse, individually raised teeth designed to quickly shape and smooth soft materials like wood, offering aggressive material removal and a rougher finish. In contrast, a metal file has finer, closely spaced teeth suited for precise smoothing and shaping on harder surfaces such as metal or plastic, producing a smoother finish. Choosing between a wood rasp and a metal file depends on the material being worked on and the desired level of surface finish.

Table of Comparison

| Feature | Wood Rasp | Metal File |

|---|---|---|

| Material Used On | Wood, soft materials | Metal, hard materials |

| Teeth Type | Coarse, individually raised teeth | Fine, sharp ridged teeth |

| Cutting Action | Aggressive material removal | Smoother, precision shaping |

| Durability | Less durable on metals | Highly durable for metals |

| Best Use | Sculpting wood, shaping soft materials | Shaping metal, finishing hard surfaces |

| Common Sizes | 6 to 12 inches | 5 to 10 inches |

Introduction to Wood Rasps and Metal Files

Wood rasps feature coarse, individually raised teeth ideal for rapidly shaping soft materials like wood, while metal files possess finer, closely spaced teeth suited for smoothing and finishing harder surfaces such as metal. The design of wood rasps allows aggressive material removal and rough contouring, whereas metal files offer precision and control for detailed work. Choosing between a wood rasp and a metal file depends on the application's material hardness and desired surface finish.

Key Differences Between Wood Rasps and Metal Files

Wood rasps feature coarse, individually raised teeth ideal for rapidly shaping soft materials like wood, while metal files have finer, closely spaced teeth designed for smoothing and finishing harder metals. The tooth pattern on wood rasps is more aggressive, enabling efficient wood removal, whereas metal files offer precision in refining metal edges. Material composition also differs; wood rasps often have softer steel to prevent clogging with wood fibers, while metal files are made from hardened steel to maintain sharpness on tougher surfaces.

Materials Best Suited for Wood Rasps vs Metal Files

Wood rasps are specifically designed with coarse, individually raised teeth ideal for shaping soft materials like wood, making them effective for removing large amounts of wood quickly without clogging. Metal files feature finer, sharper teeth arranged in parallel patterns, optimized for working on harder materials such as steel, aluminum, and other metals, providing precise control and smooth finishes. Selecting the correct tool depends on the material hardness; wood rasps excel in woodworking, while metal files are essential for metalworking tasks.

Design and Structure: Wood Rasp vs Metal File

Wood rasps feature coarse, individually raised teeth arranged in irregular patterns, designed to rapidly remove soft materials like wood through aggressive scraping. Metal files possess finer, uniformly cut teeth often organized in parallel rows, optimized for smoothing and shaping harder metals with precision. The design variation between wood rasps and metal files directly impacts their effectiveness, durability, and application on different material types.

Applications of Wood Rasps in Woodworking

Wood rasps excel in shaping and smoothing softwood and hardwood surfaces due to their coarse, individually raised teeth designed to remove material quickly. They are ideal for sculpting intricate curves and contours in wood, making them indispensable for carpenters, luthiers, and woodcarvers. Unlike metal files, which suit finer finishing on metals, wood rasps provide efficient stock removal and control in woodworking applications.

Applications of Metal Files in Metalworking

Metal files are essential tools in metalworking, used for shaping, smoothing, and deburring metal surfaces with precision. Unlike wood rasps, which are coarse and designed for softer materials, metal files feature fine, closely spaced teeth that allow for controlled material removal on steels, aluminum, and other alloys. Common applications include finishing welds, refining machined parts, and fitting metal components in fabrication and repair tasks.

Pros and Cons: Wood Rasps vs Metal Files

Wood rasps feature coarse, individually raised teeth ideal for rapid material removal on soft woods, offering precise shaping but can clog easily. Metal files provide finer, uniform teeth suited for smoothing and finishing harder metals, delivering high accuracy yet require more effort on wood. Selecting between wood rasps and metal files depends on the workload, material hardness, and desired surface finish.

How to Choose the Right Tool for Your Project

Choosing between a wood rasp and a metal file depends on the material and desired finish of your project. Wood rasps, with their coarse, individually raised teeth, are ideal for rapidly shaping soft materials like wood and removing large amounts of material. Metal files, featuring finer, uniformly spaced teeth, provide precision and smoother finishes suitable for hard metals and delicate detail work.

Maintenance and Care for Wood Rasps and Metal Files

Wood rasps require regular cleaning with a stiff brush to remove wood fibers embedded between the teeth, preventing clogging and maintaining cutting efficiency. Metal files also demand routine cleaning using a file card or wire brush to clear metal shavings and debris, which helps avoid rust and prolong tool life. Both tools benefit from proper storage in a dry environment to prevent moisture damage and ensure long-lasting performance.

Safety Tips When Using Wood Rasps and Metal Files

Wear protective gloves and safety goggles when using wood rasps and metal files to prevent injuries from sharp edges and flying particles. Secure the workpiece firmly with clamps to avoid slips that can lead to cuts or abrasions. Maintain proper hand positioning away from the cutting surface and regularly check tools for damage to ensure safe operation.

wood rasp vs metal file Infographic

productdif.com

productdif.com