Jig grinding excels in achieving high-precision finishes and tight tolerances on complex shapes, especially in tool and die making, while surface grinding is ideal for producing flat, smooth surfaces on simpler workpieces. Jig grinders utilize a fine grinding wheel to refine holes, slots, and contours with exceptional accuracy compared to surface grinders that primarily handle flat surfaces. Choosing between jig grinding and surface grinding depends on the complexity of the part and the level of precision required.

Table of Comparison

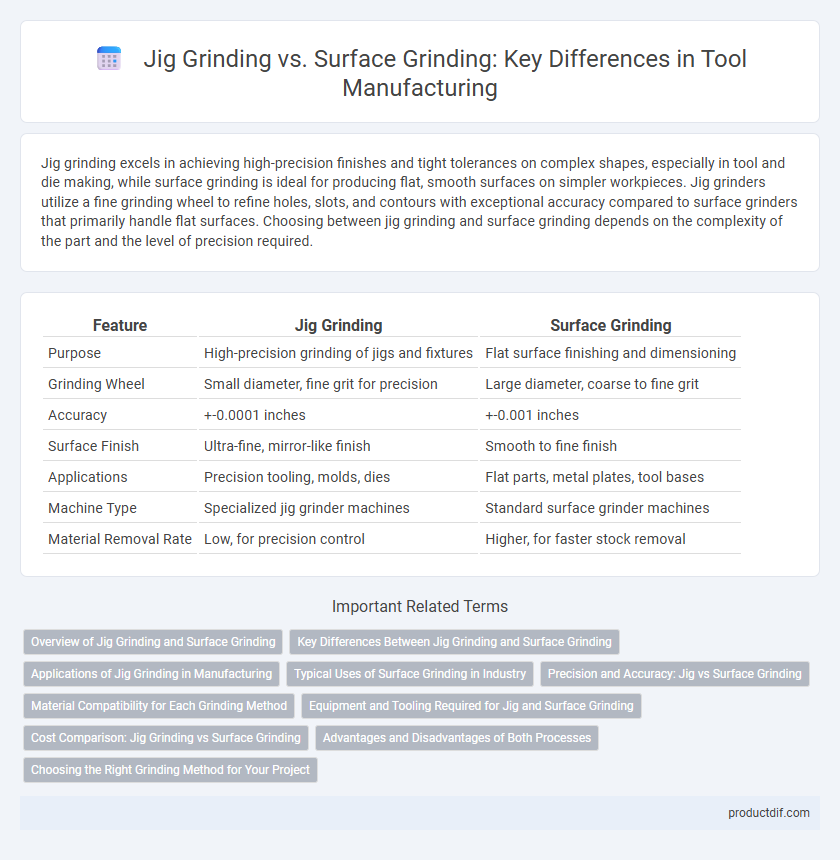

| Feature | Jig Grinding | Surface Grinding |

|---|---|---|

| Purpose | High-precision grinding of jigs and fixtures | Flat surface finishing and dimensioning |

| Grinding Wheel | Small diameter, fine grit for precision | Large diameter, coarse to fine grit |

| Accuracy | +-0.0001 inches | +-0.001 inches |

| Surface Finish | Ultra-fine, mirror-like finish | Smooth to fine finish |

| Applications | Precision tooling, molds, dies | Flat parts, metal plates, tool bases |

| Machine Type | Specialized jig grinder machines | Standard surface grinder machines |

| Material Removal Rate | Low, for precision control | Higher, for faster stock removal |

Overview of Jig Grinding and Surface Grinding

Jig grinding is a precision machining process designed to produce intricate shapes and tight tolerances on hardened materials, often used for finishing jigs, dies, and specialized components. Surface grinding, in contrast, focuses on producing flat, smooth surfaces by removing material from a workpiece using a rotating abrasive wheel, suitable for a wide range of materials and applications. Both processes utilize grinding wheels but differ in application scope, with jig grinding emphasizing accuracy and complex contours, while surface grinding prioritizes flatness and surface finish.

Key Differences Between Jig Grinding and Surface Grinding

Jig grinding provides high-precision finishing ideal for complex shapes and tight tolerances, using a small grinding wheel guided by a jig, while surface grinding targets flat surfaces with a larger wheel for more general machining tasks. Jig grinding excels in achieving intricate contours and precise hole sizes, whereas surface grinding focuses on producing smooth, flat surfaces on metal parts. The key differences lie in their application specificity, grinding wheel size, and the level of accuracy each process offers.

Applications of Jig Grinding in Manufacturing

Jig grinding is primarily used in manufacturing for achieving high-precision finishing and intricate surface contours on dies, molds, and jigs, which require extremely tight tolerances. This tool excels in applications demanding smooth surfaces and precise dimensions, such as aerospace component production and complex mechanical assemblies. Unlike surface grinding, which handles larger flat areas, jig grinding is ideal for machining complex geometries and critical hole finishes with superior accuracy.

Typical Uses of Surface Grinding in Industry

Surface grinding is commonly used in manufacturing industries to achieve high-precision flat surfaces on metal components, enhancing dimensional accuracy and surface finish. Typical applications include sharpening cutting tools, producing machine parts, and finishing hardened steel surfaces for automotive, aerospace, and mold-making sectors. This process is essential for preparing parts requiring tight tolerances and smooth finishes before assembly or further machining.

Precision and Accuracy: Jig vs Surface Grinding

Jig grinding offers superior precision and accuracy by providing finely controlled grinding of complex shapes and tight tolerances in intricate components. Surface grinding primarily focuses on creating flat surfaces with high dimensional accuracy but lacks the detailed contouring capabilities of jig grinding. The enhanced control in jig grinding ensures minimal deviation and optimal consistency, crucial for manufacturing precision-engineered tools and parts.

Material Compatibility for Each Grinding Method

Jig grinding excels in finishing hardened tool steels, carbides, and intricate alloys with high precision, making it ideal for complex shapes and fine tolerances. Surface grinding is best suited for softer materials such as cast iron, mild steel, and non-ferrous metals, providing smooth flat surfaces and consistent thickness. Material compatibility depends on the grinding wheel type and machine capability, with jig grinding tolerating tougher, high-hardness materials due to its spindle speed and coolant control.

Equipment and Tooling Required for Jig and Surface Grinding

Jig grinding requires specialized equipment such as high-precision jig grinders equipped with small-diameter grinding wheels to achieve tight tolerances and intricate shapes, often using diamond or silicon carbide abrasives. Surface grinding employs broader machines with a larger grinding wheel to produce flat surfaces, typically utilizing aluminum oxide or cubic boron nitride (CBN) wheels. Both processes demand dedicated fixtures and tooling for stable workpiece holding, but jig grinding necessitates more complex, accurate tooling for geometric precision.

Cost Comparison: Jig Grinding vs Surface Grinding

Jig grinding typically incurs higher costs due to its precision and complexity, involving specialized equipment and skilled operators. Surface grinding offers a more cost-effective option for simpler, flat surface finishes, with lower operational and maintenance expenses. The choice impacts overall budget, balancing precision requirements against machining costs.

Advantages and Disadvantages of Both Processes

Jig grinding offers high precision and fine surface finishes, making it ideal for complex shapes and small parts, but it tends to be slower and more costly compared to surface grinding. Surface grinding excels in producing flat, smooth surfaces quickly and efficiently on larger, simpler workpieces, though it lacks the intricate detailing capabilities of jig grinding. Both processes complement each other in manufacturing, with jig grinding favored for accuracy and surface grinding preferred for speed and volume.

Choosing the Right Grinding Method for Your Project

Selecting the appropriate grinding method depends on the project's precision and finish requirements; jig grinding offers superior accuracy for complex contours and tight tolerances, ideal for intricate tooling components. Surface grinding is more efficient for flat surfaces and larger workpieces, providing a smooth finish with faster material removal rates. Evaluating factors such as workpiece geometry, desired surface finish, and production volume ensures the correct grinding process for optimal results.

Jig Grinding vs Surface Grinding Infographic

productdif.com

productdif.com