A pipe wrench features serrated jaws designed to grip round pipes securely, making it ideal for plumbing tasks. An adjustable wrench has smooth jaws that adjust to fit various nut and bolt sizes, providing versatility for mechanical work. Choosing between the two depends on whether you need a tool for plumbing applications or general fastening tasks.

Table of Comparison

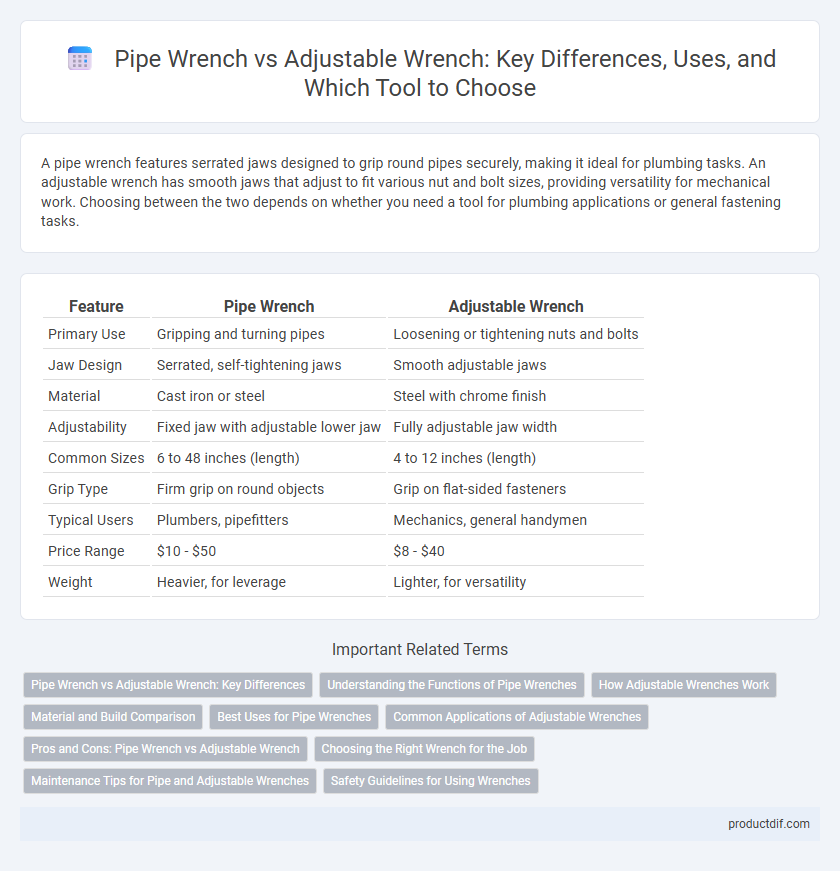

| Feature | Pipe Wrench | Adjustable Wrench |

|---|---|---|

| Primary Use | Gripping and turning pipes | Loosening or tightening nuts and bolts |

| Jaw Design | Serrated, self-tightening jaws | Smooth adjustable jaws |

| Material | Cast iron or steel | Steel with chrome finish |

| Adjustability | Fixed jaw with adjustable lower jaw | Fully adjustable jaw width |

| Common Sizes | 6 to 48 inches (length) | 4 to 12 inches (length) |

| Grip Type | Firm grip on round objects | Grip on flat-sided fasteners |

| Typical Users | Plumbers, pipefitters | Mechanics, general handymen |

| Price Range | $10 - $50 | $8 - $40 |

| Weight | Heavier, for leverage | Lighter, for versatility |

Pipe Wrench vs Adjustable Wrench: Key Differences

Pipe wrenches feature serrated jaws designed to grip round objects like pipes securely, while adjustable wrenches have smooth jaws suited for hexagonal nuts and bolts. The pipe wrench's leverage comes from its angled design, allowing it to maintain a strong grip under pressure, whereas the adjustable wrench emphasizes versatility with its adjustable jaw width. Understanding these key differences ensures optimal tool selection for plumbing versus general mechanical tasks.

Understanding the Functions of Pipe Wrenches

Pipe wrenches are specifically designed for gripping and turning round pipes and fittings due to their serrated jaws and adjustable opening, providing a secure hold on irregular surfaces. Unlike adjustable wrenches, which are best suited for hexagonal nuts and bolts, pipe wrenches apply torque without slipping, making them essential for plumbing tasks. Their heavy-duty construction and self-tightening mechanism enhance leverage, preventing damage to the pipe while ensuring a firm grip.

How Adjustable Wrenches Work

Adjustable wrenches work by using a movable jaw that slides along a worm gear to fit various sizes of nuts and bolts, offering flexibility in gripping different fasteners without the need for multiple tools. The adjustable mechanism allows precise tightening and loosening by securely clamping onto flat-sided fasteners, making it ideal for general maintenance and repair tasks. Unlike pipe wrenches that rely on serrated jaws for gripping round pipes, adjustable wrenches conduct torque through smooth surfaces to avoid damaging hardware.

Material and Build Comparison

Pipe wrenches typically feature durable cast iron bodies with hardened steel jaws for superior grip and resistance to wear, designed specifically for heavy-duty plumbing tasks. Adjustable wrenches commonly utilize high-grade chrome-vanadium steel with a polished chrome finish, offering corrosion resistance and a smooth, adjustable jaw mechanism suited for various bolt sizes. Both tools emphasize durability, but pipe wrenches prioritize torque and grip strength, while adjustable wrenches focus on precision and versatility in their build materials.

Best Uses for Pipe Wrenches

Pipe wrenches excel in gripping and turning round objects such as pipes and fittings due to their serrated jaws and adjustable pivoting head. They are best used in plumbing tasks requiring strong torque to tighten or loosen pipe connections securely. Unlike adjustable wrenches, pipe wrenches prevent slippage on smooth, cylindrical surfaces, making them indispensable for pipework maintenance and installation.

Common Applications of Adjustable Wrenches

Adjustable wrenches are commonly used for loosening and tightening nuts and bolts of various sizes in plumbing, automotive repair, and general maintenance tasks due to their versatile jaw design. Their adjustable jaw allows for easy adaptation to different fasteners, making them ideal for working on household fixtures, bicycles, and machinery without needing multiple spanners. These wrenches provide precise grip and control, reducing the risk of rounding off fastener edges during repairs or installations.

Pros and Cons: Pipe Wrench vs Adjustable Wrench

Pipe wrenches provide superior grip and leverage on rounded pipes, making them ideal for plumbing tasks but are heavier and bulkier than adjustable wrenches. Adjustable wrenches offer versatility for nuts and bolts of various sizes, are lighter and easier to maneuver, but can slip on smooth or rounded surfaces, risking damage. Both tools serve distinct purposes: pipe wrenches excel in pipework strength and durability, while adjustable wrenches prioritize flexibility and convenience.

Choosing the Right Wrench for the Job

Choosing the right wrench depends on the specific task and materials involved; pipe wrenches are designed for gripping and turning round pipes with a serrated jaw for maximum traction, while adjustable wrenches offer smooth, flat jaws suitable for hexagonal nuts and bolts. Pipe wrenches provide superior torque and grip on plumbing pipes but can damage fasteners if misused, whereas adjustable wrenches deliver versatility and precision without marking surfaces. Assess the wrench size, jaw type, and application requirements to ensure optimal performance and tool longevity.

Maintenance Tips for Pipe and Adjustable Wrenches

Regularly clean pipe wrenches and adjustable wrenches after use to remove dirt and grease, preventing rust and ensuring smooth operation. Apply a light coat of oil on the moving parts and teeth to maintain flexibility and grip strength. Store both tools in a dry environment and check for wear or damage periodically to extend their lifespan and maintain optimal performance.

Safety Guidelines for Using Wrenches

When using pipe wrenches and adjustable wrenches, always ensure the correct size and type for the job to prevent slipping and injury. Secure grip is crucial; pipe wrenches require firm teeth engagement on pipes, while adjustable wrenches must be tightly adjusted to the fastener to avoid rounding edges. Regularly inspect tools for wear or damage, and use appropriate personal protective equipment such as gloves and eye protection to enhance safety during operation.

Pipe Wrench vs Adjustable Wrench Infographic

productdif.com

productdif.com