Lean manufacturing emphasizes waste reduction and process flow optimization to enhance efficiency, while Six Sigma focuses on minimizing variation and defects through data-driven analysis and statistical methods. Integrating Lean and Six Sigma creates a comprehensive approach that improves quality and productivity by streamlining operations and ensuring consistent, measurable results. Both methodologies use specific tools and techniques to identify root causes and implement sustainable improvements in manufacturing processes.

Table of Comparison

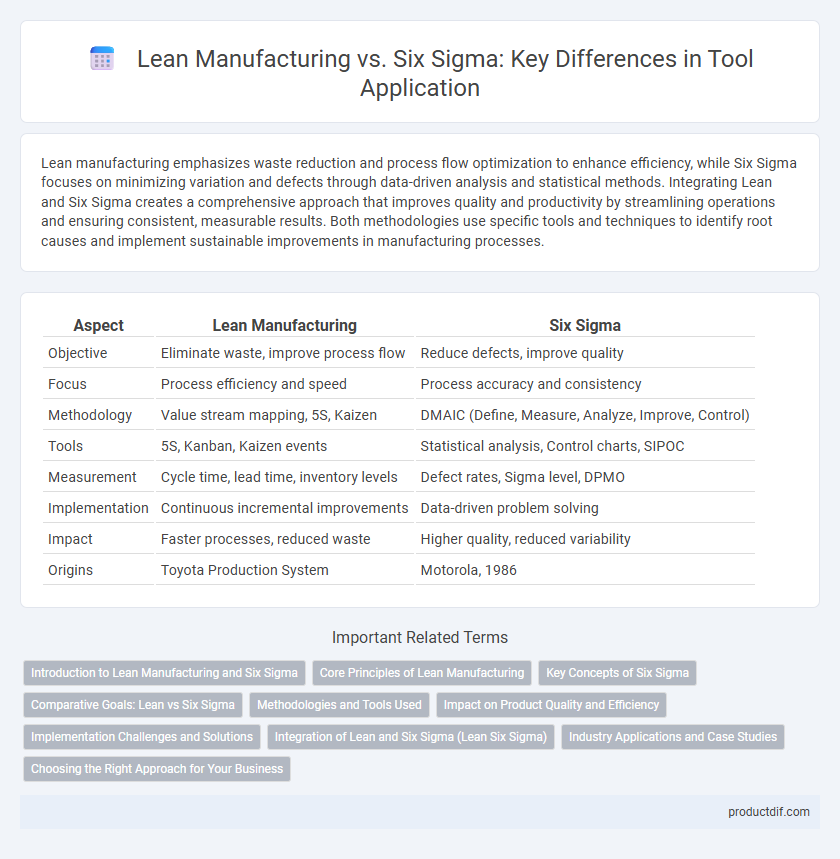

| Aspect | Lean Manufacturing | Six Sigma |

|---|---|---|

| Objective | Eliminate waste, improve process flow | Reduce defects, improve quality |

| Focus | Process efficiency and speed | Process accuracy and consistency |

| Methodology | Value stream mapping, 5S, Kaizen | DMAIC (Define, Measure, Analyze, Improve, Control) |

| Tools | 5S, Kanban, Kaizen events | Statistical analysis, Control charts, SIPOC |

| Measurement | Cycle time, lead time, inventory levels | Defect rates, Sigma level, DPMO |

| Implementation | Continuous incremental improvements | Data-driven problem solving |

| Impact | Faster processes, reduced waste | Higher quality, reduced variability |

| Origins | Toyota Production System | Motorola, 1986 |

Introduction to Lean Manufacturing and Six Sigma

Lean Manufacturing emphasizes waste reduction and process flow optimization to increase efficiency and minimize costs. Six Sigma focuses on reducing process variation and improving quality through data-driven decision-making and statistical analysis. Both methodologies aim to enhance operational performance by systematically identifying and eliminating inefficiencies.

Core Principles of Lean Manufacturing

Lean manufacturing centers on eliminating waste, optimizing flow, and delivering value efficiently by emphasizing continuous improvement and respect for people. Its core principles include defining value from the customer's perspective, mapping the value stream to identify and remove non-value-added activities, creating continuous workflow, establishing pull systems, and pursuing perfection through iterative refinement. These principles drive operational efficiency, reduce lead times, and enhance quality by fostering a culture of proactive problem-solving and waste reduction.

Key Concepts of Six Sigma

Six Sigma emphasizes reducing process variation and defects through data-driven decision-making and statistical analysis, targeting a goal of no more than 3.4 defects per million opportunities. Its core methodology, DMAIC (Define, Measure, Analyze, Improve, Control), structures problem-solving to enhance quality and efficiency. Lean manufacturing integrates with Six Sigma by focusing on waste elimination, but Six Sigma's unique strength lies in its rigorous measurement and control of process performance.

Comparative Goals: Lean vs Six Sigma

Lean manufacturing aims to maximize value by eliminating waste and improving process flow, focusing on speed and efficiency. Six Sigma targets defect reduction and process variation control through statistical analysis, emphasizing quality and consistency. While Lean streamlines operations, Six Sigma enhances precision; together, they drive operational excellence by addressing different facets of manufacturing performance.

Methodologies and Tools Used

Lean manufacturing emphasizes waste reduction through value stream mapping, 5S organization, and Kaizen continuous improvement cycles, focusing on enhancing process flow and efficiency. Six Sigma utilizes statistical tools like DMAIC (Define, Measure, Analyze, Improve, Control), control charts, and root cause analysis to reduce process variation and improve quality. Both methodologies integrate problem-solving tools, but Lean targets workflow elimination of non-value activities while Six Sigma drives data-driven defect reduction.

Impact on Product Quality and Efficiency

Lean manufacturing improves product quality and efficiency by eliminating waste and optimizing production flow, resulting in faster cycle times and reduced defects. Six Sigma emphasizes reducing variability and defects through data-driven methodologies, enhancing product consistency and reliability. Combining Lean's focus on speed with Six Sigma's precision drives superior operational performance and higher-quality outcomes.

Implementation Challenges and Solutions

Lean manufacturing faces implementation challenges such as resistance to cultural change and difficulty in maintaining continuous flow, which can be addressed through comprehensive employee training and leadership commitment. Six Sigma struggles with complexity in data analysis and sustaining long-term project momentum, mitigated by selecting experienced Black Belts and fostering cross-functional collaboration. Integrating both methods requires balancing Lean's speed with Six Sigma's precision, achievable by aligning project goals and utilizing combined toolsets for process improvement.

Integration of Lean and Six Sigma (Lean Six Sigma)

Lean Six Sigma integrates Lean manufacturing's focus on waste reduction with Six Sigma's emphasis on process variation and quality control, creating a powerful methodology for operational excellence. By combining Lean's tools like value stream mapping with Six Sigma's DMAIC framework, organizations achieve faster cycle times, higher product quality, and reduced costs. This integration drives continuous improvement by leveraging data-driven decision-making and eliminating non-value-added activities simultaneously.

Industry Applications and Case Studies

Lean manufacturing emphasizes waste reduction and process flow improvements, widely applied in automotive and electronics industries to enhance production speed and minimize costs. Six Sigma targets defect reduction and process variation control, with notable case studies in healthcare and aerospace demonstrating improved quality and compliance. Integrating Lean and Six Sigma tools in manufacturing sectors results in optimized operations, reduced lead times, and higher customer satisfaction.

Choosing the Right Approach for Your Business

Lean manufacturing emphasizes waste reduction and process flow efficiency, making it ideal for businesses aiming to streamline operations and minimize costs. Six Sigma focuses on reducing variability and improving quality through statistical analysis, best suited for companies seeking to enhance product precision and customer satisfaction. Selecting the right approach depends on whether your primary goal is operational speed and waste elimination or defect reduction and consistency improvement.

Lean manufacturing vs Six Sigma Infographic

productdif.com

productdif.com