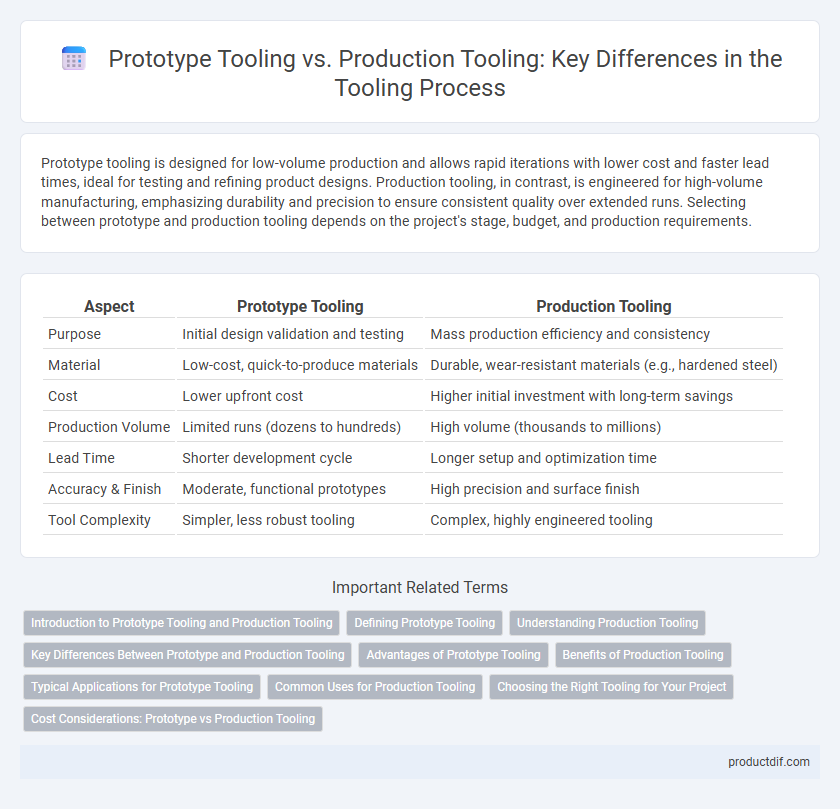

Prototype tooling is designed for low-volume production and allows rapid iterations with lower cost and faster lead times, ideal for testing and refining product designs. Production tooling, in contrast, is engineered for high-volume manufacturing, emphasizing durability and precision to ensure consistent quality over extended runs. Selecting between prototype and production tooling depends on the project's stage, budget, and production requirements.

Table of Comparison

| Aspect | Prototype Tooling | Production Tooling |

|---|---|---|

| Purpose | Initial design validation and testing | Mass production efficiency and consistency |

| Material | Low-cost, quick-to-produce materials | Durable, wear-resistant materials (e.g., hardened steel) |

| Cost | Lower upfront cost | Higher initial investment with long-term savings |

| Production Volume | Limited runs (dozens to hundreds) | High volume (thousands to millions) |

| Lead Time | Shorter development cycle | Longer setup and optimization time |

| Accuracy & Finish | Moderate, functional prototypes | High precision and surface finish |

| Tool Complexity | Simpler, less robust tooling | Complex, highly engineered tooling |

Introduction to Prototype Tooling and Production Tooling

Prototype tooling involves the creation of preliminary molds or tools used for testing and validating design concepts before full-scale manufacturing. Production tooling refers to the final, high-precision tools designed for large-volume manufacturing, ensuring consistent quality and efficiency. Understanding the differences in material selection, cost, and durability is crucial for optimizing product development cycles.

Defining Prototype Tooling

Prototype tooling involves creating specialized tools or molds designed for producing initial sample parts or limited quantities, facilitating design validation and functional testing before full-scale manufacturing. This tooling is typically less durable and faster to produce than production tooling, allowing rapid iterations and adjustments during product development. Key characteristics include lower cost, quicker turnaround time, and suitability for small batch runs, enabling efficient assessment of form, fit, and function.

Understanding Production Tooling

Production tooling involves creating durable, high-precision molds or dies designed for mass manufacturing, ensuring consistent product quality and efficiency. These tools are fabricated with robust materials such as hardened steel to withstand high-volume cycles and maintain tight tolerances. Understanding the specifics of production tooling is critical for optimizing manufacturing processes, reducing downtime, and meeting large-scale production demands effectively.

Key Differences Between Prototype and Production Tooling

Prototype tooling uses low-cost materials and simplified designs to quickly produce initial product samples, enabling rapid iteration and testing. Production tooling involves durable, high-precision molds made from hardened steel or aluminum designed for mass manufacturing, ensuring consistent quality and long-term use. Key differences include cost, material durability, production speed, and the intended volume of parts produced.

Advantages of Prototype Tooling

Prototype tooling offers rapid turnaround times and cost-effective production for low-volume runs, enabling faster design validation and iteration. It allows manufacturers to identify and resolve design flaws early, reducing risks before committing to high-cost production tooling. This flexibility accelerates product development cycles and minimizes upfront investment compared to production tooling.

Benefits of Production Tooling

Production tooling offers superior durability and precision compared to prototype tooling, enabling the manufacture of high-volume parts with consistent quality. It reduces unit costs through economies of scale and minimizes material waste by utilizing robust, long-lasting molds and dies. Enhanced tool longevity and faster cycle times in production tooling improve overall manufacturing efficiency and product reliability.

Typical Applications for Prototype Tooling

Prototype tooling is primarily used for small-scale manufacturing runs, enabling rapid iteration and design validation before full production. Typical applications include creating functional prototypes, testing design concepts, and conducting market evaluations without the high costs of production tooling. This approach supports product development cycles by reducing time-to-market and minimizing risk through early feedback.

Common Uses for Production Tooling

Production tooling is primarily used for manufacturing high volumes of finished parts with consistent quality and precision, making it ideal for long-term mass production. Common uses include injection molding, die casting, and metal stamping, where durable molds and dies enable efficient repeatability and reduced unit costs. This tooling supports industries such as automotive, consumer electronics, and medical devices where stringent quality standards and scalability are essential.

Choosing the Right Tooling for Your Project

Selecting the appropriate tooling depends on project scope, budget, and timeline, with prototype tooling offering faster turnaround and lower costs for initial design verification while production tooling ensures durability and precision for mass manufacturing. Prototype tooling typically utilizes materials like aluminum or 3D-printed molds, ideal for limited runs and functional testing. In contrast, production tooling involves hardened steel molds designed for high-volume output, yielding consistent quality and long-term cost-efficiency.

Cost Considerations: Prototype vs Production Tooling

Prototype tooling generally involves lower initial costs due to simpler designs and the use of less durable materials, making it suitable for testing and validation phases. Production tooling requires a higher upfront investment, reflecting the need for robust and precise molds capable of withstanding large-scale manufacturing runs. Cost considerations must balance the trade-off between the prototype's flexibility and the production tool's long-term efficiency and durability.

Prototype Tooling vs Production Tooling Infographic

productdif.com

productdif.com