Precision tools offer specialized design features that enable highly accurate and consistent performance, making them ideal for tasks requiring exact measurements and delicate handling. General-purpose tools provide versatility and durability across a broad range of applications but may lack the fine control needed for intricate work. Choosing between precision and general-purpose tools depends on the specific demands of the project and the level of accuracy required.

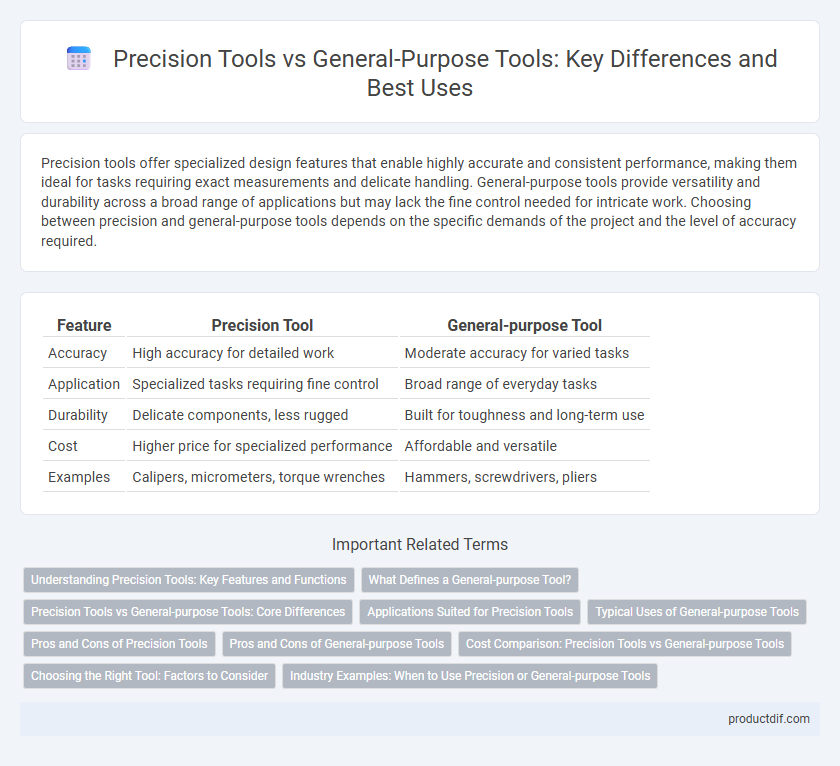

Table of Comparison

| Feature | Precision Tool | General-purpose Tool |

|---|---|---|

| Accuracy | High accuracy for detailed work | Moderate accuracy for varied tasks |

| Application | Specialized tasks requiring fine control | Broad range of everyday tasks |

| Durability | Delicate components, less rugged | Built for toughness and long-term use |

| Cost | Higher price for specialized performance | Affordable and versatile |

| Examples | Calipers, micrometers, torque wrenches | Hammers, screwdrivers, pliers |

Understanding Precision Tools: Key Features and Functions

Precision tools are designed for high accuracy and fine detail work, featuring calibrated measurements and specialized components to ensure exact results. These tools often include micrometers, dial indicators, and precision screwdrivers, which allow for consistent, repeatable performance in tasks requiring meticulous control. Their functions are critical in industries such as engineering, manufacturing, and electronics where tolerances are minimal and precision directly impacts product quality.

What Defines a General-purpose Tool?

A general-purpose tool is defined by its versatility and ability to perform a wide range of tasks across various applications, often prioritizing adaptability over specialized precision. These tools are designed to accommodate multiple functions, making them essential in everyday tasks where specific precision is not the primary requirement. Common examples include screwdrivers, hammers, and adjustable wrenches, which provide broad usability rather than function-specific accuracy.

Precision Tools vs General-purpose Tools: Core Differences

Precision tools are engineered with tight tolerances and specialized materials to deliver highly accurate measurements and cuts, making them essential for tasks requiring exactness, such as machining or calibration. General-purpose tools, designed for versatility and durability, perform adequately across a wide range of applications but lack the fine accuracy and specialized features of precision tools. The core differences lie in precision tools' focus on exactness and repeatability versus general tools' emphasis on adaptability and broad usability.

Applications Suited for Precision Tools

Precision tools excel in applications requiring exact measurements and intricate detailing, such as watchmaking, electronics assembly, and fine jewelry crafting. These tools offer enhanced accuracy, enabling engineers and artisans to achieve tight tolerances and flawless finishes. Precision tools minimize errors and improve quality in high-stakes manufacturing and specialized repair tasks.

Typical Uses of General-purpose Tools

General-purpose tools are widely used for everyday tasks such as assembling furniture, repairing household items, and basic woodworking. These tools include screwdrivers, hammers, and pliers, offering versatility across multiple applications. Their design focuses on broad functionality rather than specialized precision, making them essential for general maintenance and DIY projects.

Pros and Cons of Precision Tools

Precision tools offer superior accuracy and reliability, making them ideal for tasks requiring exact measurements and fine detailing. These tools often feature high-quality materials and specialized designs, which can increase durability but also raise costs and reduce versatility compared to general-purpose tools. However, their limited application range and higher maintenance needs may deter those seeking flexible, multi-use options.

Pros and Cons of General-purpose Tools

General-purpose tools offer versatility and cost-effectiveness by accommodating multiple tasks, making them ideal for users with diverse and unpredictable needs. However, they may lack the specialized accuracy and efficiency found in precision tools, potentially leading to slower work and reduced quality in tasks requiring high specificity. Their design prioritizes adaptability over optimal performance, which can result in less durability and precision in specialized applications.

Cost Comparison: Precision Tools vs General-purpose Tools

Precision tools often have higher upfront costs due to advanced materials and manufacturing processes designed for accuracy and durability. General-purpose tools typically offer lower initial prices but may incur additional expenses over time related to maintenance and replacements caused by less specialized performance. Investing in precision tools can lead to long-term savings in industries requiring exact measurements and consistent quality.

Choosing the Right Tool: Factors to Consider

Choosing the right tool depends heavily on the specific task requirements, where precision tools offer superior accuracy and fine control for detailed work, while general-purpose tools provide versatility for a wide range of applications. Material composition, ergonomics, and expected frequency of use play critical roles in selecting a tool that balances durability with user comfort. Understanding the project's complexity and desired outcome ensures optimal performance and cost-effectiveness when deciding between precision and general-purpose tools.

Industry Examples: When to Use Precision or General-purpose Tools

Precision tools are essential in industries like aerospace and electronics manufacturing, where tight tolerances and intricate components demand exact measurements and fine adjustments. General-purpose tools serve well in construction and automotive repair, where versatility and durability across a range of tasks optimize workflow and reduce equipment needs. Choosing between precision and general-purpose tools depends on the complexity of the job, required accuracy, and production volume, ensuring efficiency and product quality in industrial applications.

Precision Tool vs General-purpose Tool Infographic

productdif.com

productdif.com