Hammer drilling delivers rapid, percussive force ideal for breaking through tough concrete and masonry, while rotary drilling uses continuous rotational motion best suited for soft to medium-density materials like wood or metal. Hammer drills combine impact and rotation for efficient penetration in hard substrates, whereas rotary drills provide smoother drilling with less vibration for delicate tasks. Selecting between hammer drilling and rotary drilling depends on the material hardness and the precision required for the drilling project.

Table of Comparison

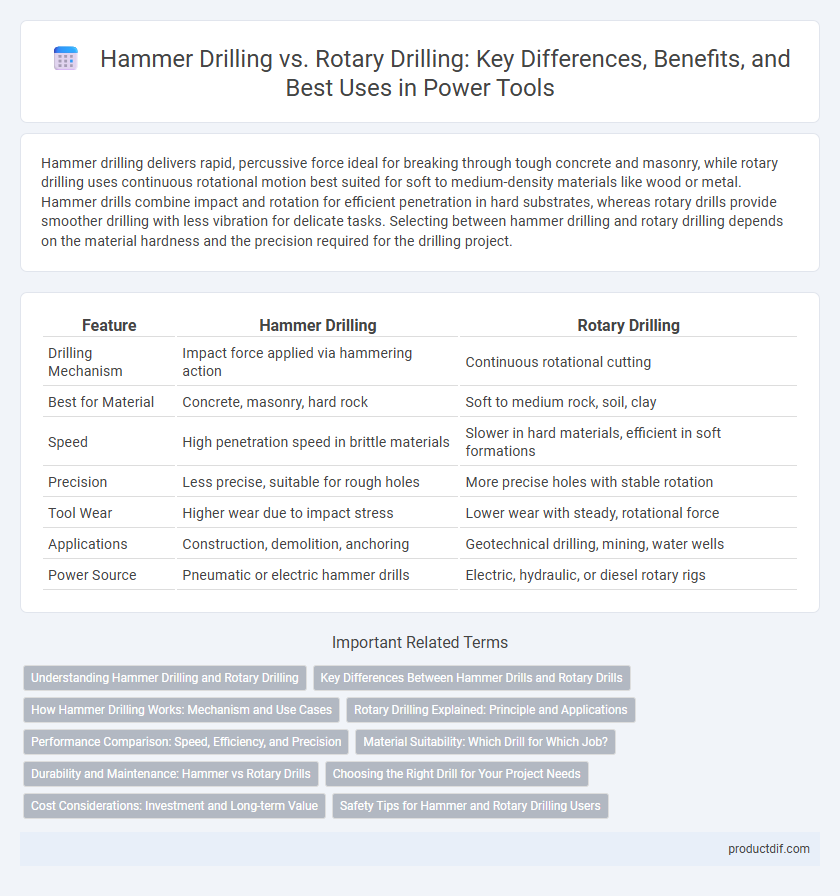

| Feature | Hammer Drilling | Rotary Drilling |

|---|---|---|

| Drilling Mechanism | Impact force applied via hammering action | Continuous rotational cutting |

| Best for Material | Concrete, masonry, hard rock | Soft to medium rock, soil, clay |

| Speed | High penetration speed in brittle materials | Slower in hard materials, efficient in soft formations |

| Precision | Less precise, suitable for rough holes | More precise holes with stable rotation |

| Tool Wear | Higher wear due to impact stress | Lower wear with steady, rotational force |

| Applications | Construction, demolition, anchoring | Geotechnical drilling, mining, water wells |

| Power Source | Pneumatic or electric hammer drills | Electric, hydraulic, or diesel rotary rigs |

Understanding Hammer Drilling and Rotary Drilling

Hammer drilling uses rapid, short hammering motions combined with rotary rotation to efficiently break through tough materials like concrete and masonry. Rotary drilling relies solely on continuous rotational force to penetrate softer materials such as wood, metal, and plastic. Understanding the distinct mechanics and ideal applications of hammer drilling and rotary drilling ensures optimal tool selection for construction and renovation projects.

Key Differences Between Hammer Drills and Rotary Drills

Hammer drilling delivers rapid impact blows combined with rotary motion, ideal for breaking through hard materials like concrete and masonry, while rotary drilling relies solely on a turning action to bore holes in softer materials such as wood and metal. Hammer drills feature a piston mechanism that generates percussive force, enhancing drilling efficiency and speed in dense surfaces compared to the steady torque of rotary drills. The key differences lie in application suitability, impact generation, and drilling speed, with hammer drills excelling in heavy-duty construction tasks and rotary drills suited for precision drilling in less resistant materials.

How Hammer Drilling Works: Mechanism and Use Cases

Hammer drilling operates by combining rotational motion with rapid, percussive blows delivered by the hammer mechanism, enabling efficient penetration of hard materials such as concrete and masonry. The internal piston or electro-mechanical system strikes the drill bit repeatedly, creating a hammering action that fractures the substrate while the rotation removes debris. This method is ideal for construction, renovation, and heavy-duty drilling tasks where speed and precision on brittle surfaces are essential.

Rotary Drilling Explained: Principle and Applications

Rotary drilling operates by rotating a drill bit to cut through rock and soil, using downward pressure combined with the bit's rotational speed to efficiently penetrate various geological formations. This method is essential in oil and gas exploration, mineral extraction, and water well drilling due to its ability to maintain continuous drilling and handle deep boreholes with precision. Advanced rotary drilling rigs incorporate technologies such as mud circulation systems and real-time monitoring to optimize drilling performance and ensure safety.

Performance Comparison: Speed, Efficiency, and Precision

Hammer drilling outperforms rotary drilling in speed when tackling hard materials like concrete and masonry, delivering rapid percussive blows that enhance penetration. Efficiency is higher in hammer drilling due to its dual action mode that combines impact and rotation, reducing effort and time needed for hole creation compared to rotary drilling's slower rotational method. While rotary drilling offers greater precision on softer materials or metal surfaces, hammer drilling excels in maintaining accuracy on dense substrates, balancing power and control to minimize bit wandering.

Material Suitability: Which Drill for Which Job?

Hammer drilling excels in penetrating hard, brittle materials such as concrete, masonry, and stone thanks to its rapid pounding action combined with rotation, making it ideal for tough construction and demolition tasks. Rotary drilling is better suited for softer materials like wood, metal, and plastic, providing smooth, continuous rotation that ensures precision and clean holes in manufacturing or woodworking projects. Selecting the right drill depends on material hardness and project requirements, with hammer drills preferred for dense substrates and rotary drills for more delicate or uniform materials.

Durability and Maintenance: Hammer vs Rotary Drills

Hammer drills offer superior durability due to their percussive mechanism, which withstands heavy-duty tasks with less wear compared to rotary drills. Rotary drills require more frequent maintenance because their continuous rotational motion generates higher friction and heat, accelerating component degradation. The robust design of hammer drills reduces downtime and maintenance costs, making them ideal for tough materials like concrete and masonry.

Choosing the Right Drill for Your Project Needs

Hammer drilling excels in cutting through tough materials like concrete and masonry by delivering rapid, powerful percussive blows, making it ideal for construction projects requiring precision and durability. Rotary drilling, on the other hand, provides continuous rotational force suited for softer materials such as wood, metal, and plastic, ensuring smoother holes and versatility in various applications. Selecting between hammer and rotary drilling depends on the material hardness, drill bit type, and the specific requirements of your project to optimize efficiency and achieve professional results.

Cost Considerations: Investment and Long-term Value

Hammer drilling typically requires higher initial investment due to specialized equipment and robust drill bits designed for harder materials, while rotary drilling often involves lower upfront costs with more versatile machinery. Long-term value in hammer drilling is realized through increased efficiency and durability in concrete or masonry applications, reducing operational downtime and maintenance expenses. Rotary drilling offers broader application potential in softer substrates, balancing moderate maintenance costs with greater flexibility across projects.

Safety Tips for Hammer and Rotary Drilling Users

Hammer drilling and rotary drilling require specific safety precautions to prevent accidents and injuries on the job site. Users should always wear protective gear such as safety goggles, ear protection, gloves, and dust masks to guard against flying debris, dust inhalation, and loud noise exposure. It is essential to inspect equipment before use, secure the workpiece firmly, and maintain correct posture while operating drills to minimize the risk of slips, electric shock, and repetitive strain injuries.

Hammer drilling vs Rotary drilling Infographic

productdif.com

productdif.com