Hard anodizing creates a thicker, denser oxide layer on tools, significantly enhancing wear and corrosion resistance compared to soft anodizing. This process results in a harder surface ideal for heavy-duty applications requiring extended tool life. Soft anodizing produces a thinner coating, offering moderate protection and better electrical insulation without significantly altering the tool's dimensions.

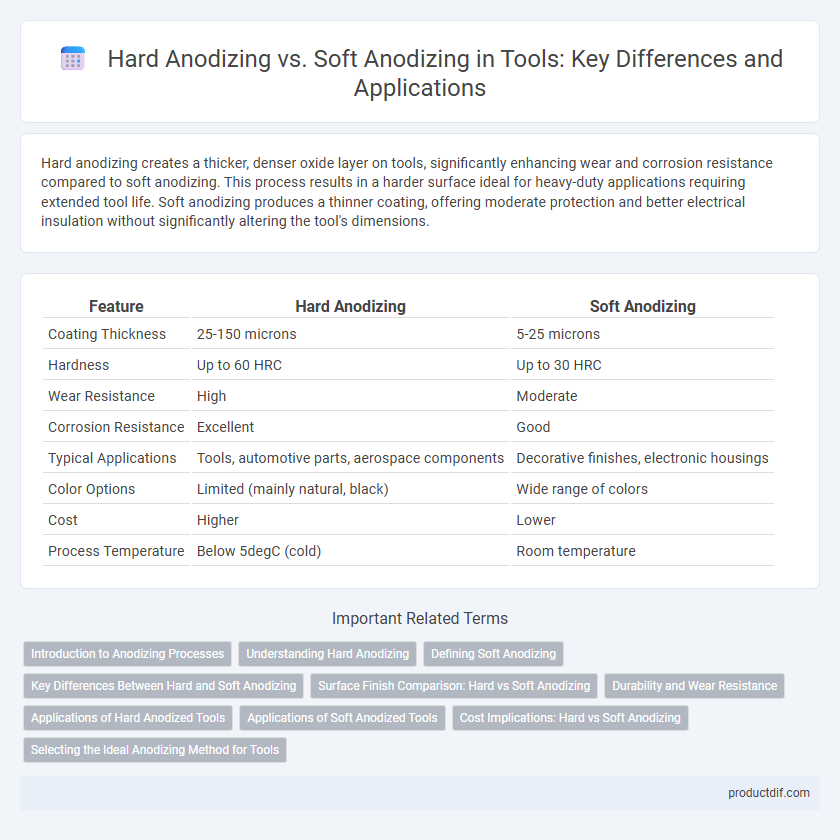

Table of Comparison

| Feature | Hard Anodizing | Soft Anodizing |

|---|---|---|

| Coating Thickness | 25-150 microns | 5-25 microns |

| Hardness | Up to 60 HRC | Up to 30 HRC |

| Wear Resistance | High | Moderate |

| Corrosion Resistance | Excellent | Good |

| Typical Applications | Tools, automotive parts, aerospace components | Decorative finishes, electronic housings |

| Color Options | Limited (mainly natural, black) | Wide range of colors |

| Cost | Higher | Lower |

| Process Temperature | Below 5degC (cold) | Room temperature |

Introduction to Anodizing Processes

Hard anodizing creates a thick, dense oxide layer that enhances surface hardness and wear resistance, making it ideal for heavy-duty tools and industrial applications. Soft anodizing produces a thinner oxide layer that improves corrosion resistance and surface appearance, commonly used in decorative and lightweight components. Both processes use electrochemical oxidation but differ in voltage, temperature, and electrolyte composition, resulting in distinct protective and functional characteristics.

Understanding Hard Anodizing

Hard anodizing creates a dense, wear-resistant oxide layer on aluminum surfaces, significantly enhancing durability and corrosion resistance for heavy-duty tool applications. This process involves low-temperature electrochemical treatment, resulting in a thicker, harder coating compared to soft anodizing, typically reaching hardness levels above 60 HRC. Hard anodized tools exhibit superior abrasion resistance and long-lasting performance, making them ideal for industrial and precision tool manufacturing.

Defining Soft Anodizing

Soft anodizing is an electrochemical process that creates a thinner, corrosion-resistant oxide layer on aluminum surfaces, enhancing durability without significantly increasing hardness. This method retains aluminum's natural ductility and is commonly used where moderate wear resistance and electrical conductivity are required. Unlike hard anodizing, soft anodizing produces a smoother finish suitable for decorative applications and light industrial use.

Key Differences Between Hard and Soft Anodizing

Hard anodizing produces a thicker, denser oxide layer that significantly enhances wear resistance and surface hardness, making it ideal for heavy-duty tool applications. Soft anodizing generates a thinner oxide coating primarily for corrosion resistance and aesthetic purposes, suitable for less demanding environments. The key differences lie in the oxide layer thickness, hardness, and resultant durability, with hard anodizing providing superior protection in abrasive and high-stress conditions.

Surface Finish Comparison: Hard vs Soft Anodizing

Hard anodizing produces a thicker, denser oxide layer with a matte to satin surface finish offering superior wear and corrosion resistance compared to soft anodizing. Soft anodizing results in a thinner oxide film with a smoother, more uniform appearance but lower hardness and durability. Surface finish in hard anodizing is ideal for heavy-duty applications requiring abrasion resistance, while soft anodizing suits decorative or light-duty uses.

Durability and Wear Resistance

Hard anodizing produces a thicker, denser oxide layer compared to soft anodizing, significantly enhancing durability and wear resistance in industrial applications. This process results in a surface hardness up to 60-70 HRC, making it ideal for high-friction tools and components exposed to abrasive environments. Soft anodizing, with its thinner oxide coating, provides moderate corrosion protection but lacks the robust mechanical properties necessary for heavy-duty wear resistance.

Applications of Hard Anodized Tools

Hard anodized tools exhibit superior wear resistance and corrosion protection, making them ideal for heavy-duty applications such as cutting, machining, and aerospace components. The dense, thick oxide layer formed through hard anodizing enhances surface hardness up to 60-70 HRC, significantly extending tool lifespan in abrasive environments. These properties enable hard anodized tools to maintain precision and performance in high-friction and high-temperature industrial processes.

Applications of Soft Anodized Tools

Soft anodized tools are primarily utilized in applications requiring corrosion resistance and improved surface durability without compromising electrical conductivity. These tools are ideal for components in the electronics industry, consumer goods, and decorative finishes due to their uniform coating and enhanced aesthetic qualities. Soft anodizing also supports lightweight tooling solutions in aerospace and automotive sectors by providing moderate protection while maintaining material flexibility.

Cost Implications: Hard vs Soft Anodizing

Hard anodizing typically incurs higher costs due to its intensive processing requirements and thicker oxide layer, which enhance durability and corrosion resistance essential for heavy-duty tools. Soft anodizing offers a more cost-effective alternative suitable for applications needing moderate surface protection and aesthetic finish, with quicker production times and less energy consumption. Choosing between hard and soft anodizing impacts overall tool manufacturing expenses, balancing budget constraints with performance needs.

Selecting the Ideal Anodizing Method for Tools

Hard anodizing creates a thicker, denser oxide layer on tools, offering superior wear resistance, corrosion protection, and enhanced surface hardness ideal for high-stress applications. Soft anodizing produces a thinner, more decorative oxide layer, suitable for tools where aesthetic appearance and moderate protection are sufficient. Selecting the ideal anodizing method depends on tool usage, required durability, and environmental exposure to maximize performance and longevity.

Hard Anodizing vs Soft Anodizing Infographic

productdif.com

productdif.com