A router in woodworking is designed to hollow out or shape wood by following a template or freehand, providing precise and intricate cuts. A shaper, on the other hand, is a larger, more powerful tool used primarily for shaping edges and molding profiles on wood, capable of handling bigger cutters and heavier stock. Choosing between a router and a shaper depends on the scale of the project, the complexity of the design, and the type of cuts required.

Table of Comparison

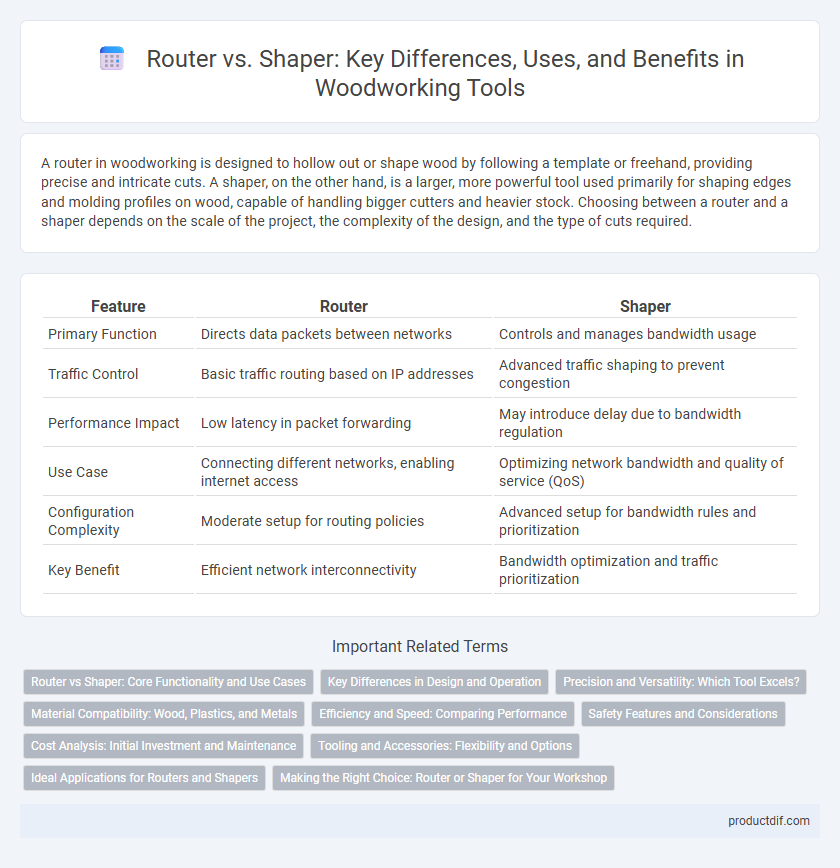

| Feature | Router | Shaper |

|---|---|---|

| Primary Function | Directs data packets between networks | Controls and manages bandwidth usage |

| Traffic Control | Basic traffic routing based on IP addresses | Advanced traffic shaping to prevent congestion |

| Performance Impact | Low latency in packet forwarding | May introduce delay due to bandwidth regulation |

| Use Case | Connecting different networks, enabling internet access | Optimizing network bandwidth and quality of service (QoS) |

| Configuration Complexity | Moderate setup for routing policies | Advanced setup for bandwidth rules and prioritization |

| Key Benefit | Efficient network interconnectivity | Bandwidth optimization and traffic prioritization |

Router vs Shaper: Core Functionality and Use Cases

Routers primarily direct data packets between different networks based on IP addresses, enabling efficient communication across the internet or local networks. Shapers control bandwidth by regulating traffic flow to prevent congestion and ensure quality of service, crucial for maintaining performance in high-demand environments. While routers manage routing paths and connectivity, shapers optimize network performance by prioritizing critical data and limiting less important traffic.

Key Differences in Design and Operation

Routers primarily direct data packets between networks based on IP addresses, using routing tables and protocols like OSPF or BGP, whereas shapers control network traffic flow by managing bandwidth allocation to ensure optimal performance and reduce congestion. Router design emphasizes packet forwarding efficiency and network connectivity, while shapers focus on traffic prioritization and rate limiting through techniques such as token bucket or leaky bucket algorithms. Effective network management often requires integrating both tools to balance data routing and traffic shaping for improved quality of service (QoS).

Precision and Versatility: Which Tool Excels?

Routers offer exceptional precision with adjustable depth control and specialized bits that deliver clean, intricate cuts ideal for detailed woodworking projects. Shapers provide greater versatility by handling larger, more complex profiles and accommodating a wider range of cutter sizes, making them suitable for heavy-duty shaping tasks. When precision in fine detailing is paramount, routers excel, whereas shapers dominate in versatility for large-scale, robust shaping applications.

Material Compatibility: Wood, Plastics, and Metals

Routers excel in shaping wood and plastics due to their high-speed rotary cutting action, providing smooth and precise edges, while specialized bits allow limited work on soft metals like aluminum. Shapers, with their slower cutting speed and heavier build, are particularly effective on harder woods and dense plastics but generally lack the versatility for clean cuts on metals. Selecting the right tool depends on the material hardness and desired finish, with routers favored for detail work in softer materials and shapers preferred for robust shaping tasks on tough woods.

Efficiency and Speed: Comparing Performance

Routers efficiently manage data traffic by directing packets based on IP addresses, optimizing network speed through intelligent path selection. Shapers regulate bandwidth allocation, ensuring consistent data flow by controlling traffic rates and minimizing congestion. In performance comparison, routers excel in maximizing throughput for varied destinations, while shapers improve efficiency by smoothing bursts and preventing network overloads.

Safety Features and Considerations

Routers feature built-in safety mechanisms such as spindle locks and electronic brakes that prevent accidental starts and ensure quick stops, reducing the risk of injury during tool changes and operation. Shapers often include guard shields and hold-down clamps to stabilize the workpiece, minimizing kickback and enhancing operator control. Both tools require proper personal protective equipment and adherence to manufacturer guidelines to maintain safety during woodworking tasks.

Cost Analysis: Initial Investment and Maintenance

Routers generally require a higher initial investment due to advanced hardware and software capabilities but offer robust traffic management and security features, reducing long-term operational costs. Shapers typically involve lower upfront costs as they focus on bandwidth allocation and traffic prioritization without extensive routing functions, but may incur higher maintenance expenses when scaling network capacity. Evaluating total cost of ownership involves balancing initial procurement prices against ongoing maintenance and performance efficiency.

Tooling and Accessories: Flexibility and Options

Router tool systems offer extensive adaptability with a wide range of bits, bases, and guide templates, enabling precise shaping and edging for diverse woodworking projects. Shapers provide robust tooling options compatible with large-diameter cutters and heavy-duty accessories, ideal for high-volume production requiring consistent profiles. Both tools accommodate various collets, fence systems, and dust collection attachments, enhancing their flexibility and operational efficiency in professional workshops.

Ideal Applications for Routers and Shapers

Routers excel in ideal applications requiring efficient routing of network packets across complex WAN and LAN environments, making them essential for enterprise data centers and large-scale network infrastructures. Shapers are ideal for bandwidth management in scenarios such as VoIP traffic regulation and streaming services, where controlling data flow and reducing latency are critical. Selecting between routers and shapers depends on network scale and the necessity for traffic prioritization versus comprehensive packet forwarding.

Making the Right Choice: Router or Shaper for Your Workshop

Selecting the right tool between a router and a shaper depends on the specific woodworking tasks and desired precision in your workshop. Routers offer versatility for edge profiling, cutting grooves, and intricate designs with handheld convenience, while shapers provide greater power and stability for shaping larger workpieces and raised panel doors. Consider factors like project scale, complexity, and budget to ensure optimal performance and efficiency in your woodworking projects.

Router vs Shaper Infographic

productdif.com

productdif.com