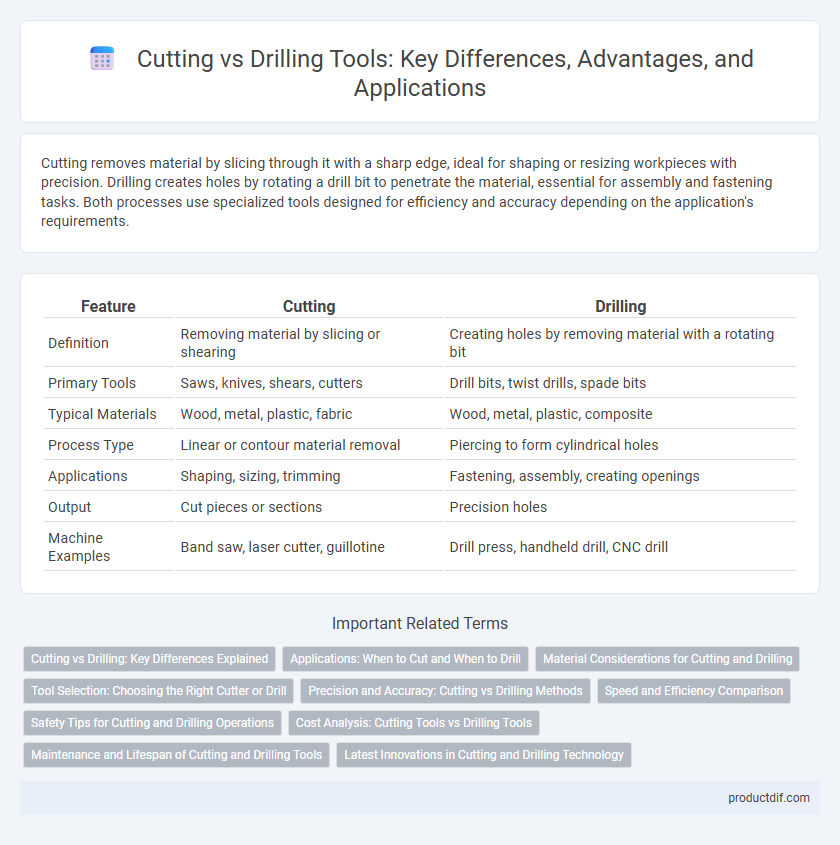

Cutting removes material by slicing through it with a sharp edge, ideal for shaping or resizing workpieces with precision. Drilling creates holes by rotating a drill bit to penetrate the material, essential for assembly and fastening tasks. Both processes use specialized tools designed for efficiency and accuracy depending on the application's requirements.

Table of Comparison

| Feature | Cutting | Drilling |

|---|---|---|

| Definition | Removing material by slicing or shearing | Creating holes by removing material with a rotating bit |

| Primary Tools | Saws, knives, shears, cutters | Drill bits, twist drills, spade bits |

| Typical Materials | Wood, metal, plastic, fabric | Wood, metal, plastic, composite |

| Process Type | Linear or contour material removal | Piercing to form cylindrical holes |

| Applications | Shaping, sizing, trimming | Fastening, assembly, creating openings |

| Output | Cut pieces or sections | Precision holes |

| Machine Examples | Band saw, laser cutter, guillotine | Drill press, handheld drill, CNC drill |

Cutting vs Drilling: Key Differences Explained

Cutting involves removing material by slicing through a workpiece with sharp edges or blades, while drilling creates holes by rotating a cutting tool into the material. Cutting tools typically produce chips or swarf, whereas drilling generates cylindrical holes and requires precise alignment. The main difference lies in their purpose: cutting shapes or separates material, whereas drilling creates openings for fasteners or passages.

Applications: When to Cut and When to Drill

Cutting is ideal for shaping or resizing materials such as metal, wood, or plastic, commonly used in fabrication and manufacturing to create precise edges or separate parts. Drilling is essential for creating holes in materials for fastening, assembly, or insertion of components, frequently applied in construction, engineering, and woodworking projects. Selecting cutting or drilling depends on whether the task requires material removal along a line or the creation of round holes for mechanical purposes.

Material Considerations for Cutting and Drilling

Material considerations for cutting and drilling vary significantly based on hardness, thickness, and composition; cutting typically requires blades optimized for toughness and wear resistance to handle metals, plastics, and composites. Drilling demands drill bits designed to maintain sharpness and dissipate heat effectively when penetrating materials such as steel, aluminum, and wood, often involving coatings like titanium nitride for enhanced durability. Selecting the appropriate tool depends on factors like material brittleness, density, and thermal conductivity to ensure precision and tool longevity.

Tool Selection: Choosing the Right Cutter or Drill

Selecting the right tool depends on the material type and desired outcome, with cutting tools optimized for shaping or separating materials and drills designed for creating precise holes. High-speed steel (HSS) cutters are ideal for cutting softer metals, while tungsten carbide drills offer superior performance in hard materials like stainless steel. Proper tool selection enhances machining efficiency, surface finish, and tool longevity.

Precision and Accuracy: Cutting vs Drilling Methods

Cutting methods offer high precision by controlling the tool path and material removal, ideal for shaping complex geometries with tight tolerances. Drilling focuses on accuracy by creating precise, correctly sized holes, often guided by templates or CNC machines to ensure exact positioning. Both methods rely on tool quality and machine calibration to achieve optimal precision and accuracy in manufacturing processes.

Speed and Efficiency Comparison

Cutting tools offer faster material removal rates in applications involving shaping or resizing, optimizing overall production speed and efficiency. Drilling tools excel in creating precise holes with minimal surface disruption, maximizing accuracy and reducing rework time. Selecting between cutting and drilling depends on task requirements, balancing speed and operational efficiency for optimal tool performance.

Safety Tips for Cutting and Drilling Operations

Wear appropriate personal protective equipment such as safety goggles, gloves, and hearing protection to prevent injury during cutting and drilling operations. Ensure tools are properly maintained and sharpened to reduce the risk of accidents caused by dull blades or bits. Secure materials firmly and use clamps to stabilize workpieces, preventing slips and enhancing precision during cutting and drilling tasks.

Cost Analysis: Cutting Tools vs Drilling Tools

Cutting tools typically incur lower initial costs compared to drilling tools due to simpler designs and materials, but drilling tools often require higher investment for precision and durability. Maintenance expenses for cutting tools are generally less frequent, whereas drilling tools demand more regular replacement of specialized bits to maintain efficiency. Overall, the total cost of ownership for cutting tools may be lower in low-volume applications, while drilling tools prove more cost-effective in high-precision, repetitive tasks.

Maintenance and Lifespan of Cutting and Drilling Tools

Cutting tools require regular sharpening and proper cooling to maintain edge integrity and extend lifespan, while drilling tools demand frequent inspection for tip wear and lubrication to prevent overheating and reduce friction. Proper maintenance of cutting tools reduces chipping and dulling, directly enhancing performance and durability. For drilling tools, timely replacement of worn bits and consistent cleaning prevent material buildup, ensuring longer operational life and precision.

Latest Innovations in Cutting and Drilling Technology

Latest innovations in cutting and drilling technology include the adoption of laser-assisted cutting and ultrasonic drilling, which significantly enhance precision and reduce material deformation. Advanced CNC machines integrated with AI algorithms optimize tool paths, increasing efficiency and extending tool life. The development of diamond-coated and carbide tools improves durability and performance in high-speed cutting and deep hole drilling applications.

Cutting vs Drilling Infographic

productdif.com

productdif.com