3D printing enables the creation of complex geometries with minimal waste by building objects layer by layer, offering greater design flexibility than subtractive manufacturing. Subtractive manufacturing removes material from a solid block, which can lead to higher material waste and limits intricate internal structures. Selecting between these methods depends on project requirements such as precision, material type, and production volume.

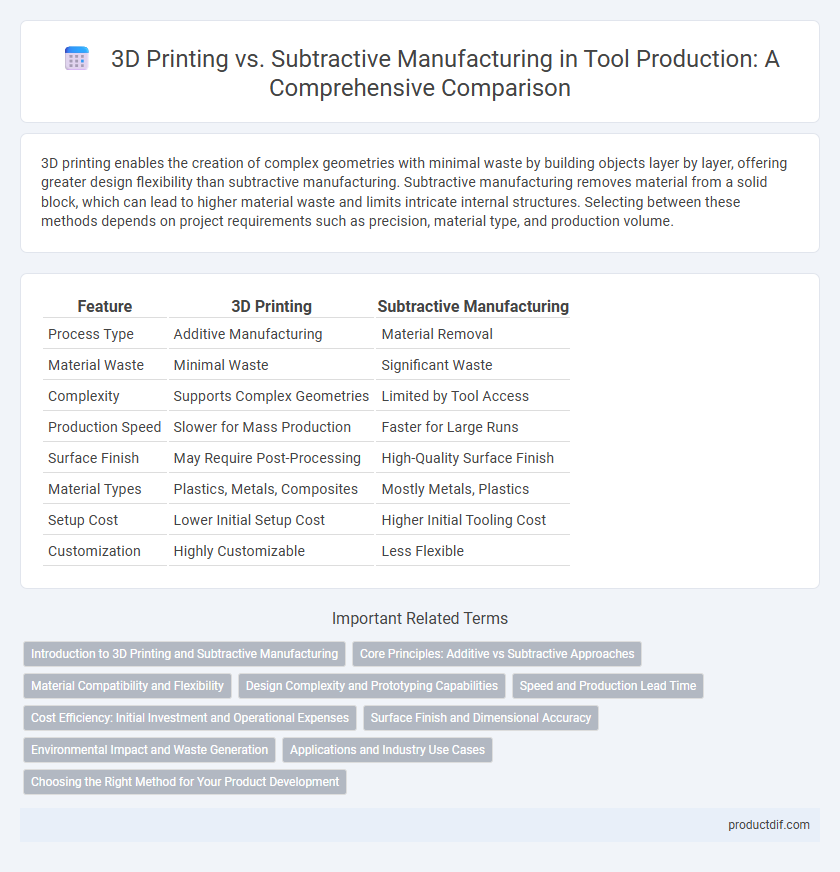

Table of Comparison

| Feature | 3D Printing | Subtractive Manufacturing |

|---|---|---|

| Process Type | Additive Manufacturing | Material Removal |

| Material Waste | Minimal Waste | Significant Waste |

| Complexity | Supports Complex Geometries | Limited by Tool Access |

| Production Speed | Slower for Mass Production | Faster for Large Runs |

| Surface Finish | May Require Post-Processing | High-Quality Surface Finish |

| Material Types | Plastics, Metals, Composites | Mostly Metals, Plastics |

| Setup Cost | Lower Initial Setup Cost | Higher Initial Tooling Cost |

| Customization | Highly Customizable | Less Flexible |

Introduction to 3D Printing and Subtractive Manufacturing

3D printing, an additive manufacturing process, builds objects layer by layer from digital models using materials like plastics, resins, or metals, enabling complex geometries and rapid prototyping. Subtractive manufacturing removes material from a solid block via machining processes such as milling, turning, or drilling, offering high precision and superior surface finishes. These contrasting methods highlight the strengths of 3D printing in design flexibility and the accuracy of subtractive techniques for final production parts.

Core Principles: Additive vs Subtractive Approaches

3D printing utilizes an additive approach, building objects layer by layer from digital models, which minimizes material waste and allows for complex geometries unattainable through traditional methods. Subtractive manufacturing relies on removing material from a solid block through machining processes like milling or turning, offering high precision and surface finish. The core principle distinction lies in material usage, process flexibility, and design freedom, with additive methods favoring customization and complexity, while subtractive techniques excel in accuracy and scalability.

Material Compatibility and Flexibility

3D printing supports a wide range of materials including plastics, resins, metals, and composites, offering high flexibility in producing complex geometries without material waste. Subtractive manufacturing excels with metals and rigid materials but is limited by tool accessibility and material brittleness, which can restrict design complexity. Material compatibility in 3D printing allows rapid prototyping and customization, whereas subtractive methods provide superior surface finish and mechanical properties for traditional manufacturing applications.

Design Complexity and Prototyping Capabilities

3D printing enables the creation of highly complex geometries and intricate internal structures that are difficult or impossible to achieve with subtractive manufacturing, allowing for greater design freedom and customization. Prototyping with additive manufacturing accelerates the iteration process by producing functional parts directly from digital models without the need for tooling, significantly reducing lead times and material waste. Subtractive manufacturing offers high precision and surface finish for simpler designs but is less efficient and more costly for producing complex prototypes.

Speed and Production Lead Time

3D printing offers rapid prototyping with significantly reduced setup and production lead times compared to subtractive manufacturing, which requires extensive tooling and material removal processes. The additive process builds parts layer by layer, enabling faster iteration and customization without the delays associated with machining or milling. This efficiency in production speed makes 3D printing ideal for low to medium volume runs, while subtractive methods remain advantageous for high-volume manufacturing where cycle times per part are critical.

Cost Efficiency: Initial Investment and Operational Expenses

3D printing typically requires a lower initial investment compared to subtractive manufacturing due to minimal tooling and setup costs. Operational expenses for 3D printing are often reduced by less material waste and lower energy consumption, while subtractive manufacturing incurs higher costs from raw material waste and machine maintenance. Over time, 3D printing proves more cost-efficient for complex, small-batch productions, whereas subtractive methods may be more economical for high-volume manufacturing due to faster production speeds.

Surface Finish and Dimensional Accuracy

3D printing offers complex geometries with moderate surface finish quality, often requiring post-processing to achieve smooth surfaces, while subtractive manufacturing delivers superior surface finish directly from the machining process. Dimensional accuracy in subtractive manufacturing typically surpasses that of 3D printing, with tolerances as tight as +-0.005 mm achievable via CNC milling. The choice between these technologies depends on the required precision and surface smoothness, with subtractive methods favored for high-accuracy, fine-finish applications.

Environmental Impact and Waste Generation

3D printing significantly reduces material waste by using additive processes that build objects layer by layer, contrasting with subtractive manufacturing's removal of excess material from a solid block. The energy consumption in 3D printing varies depending on the technology but often results in lower emissions due to minimal waste and shorter supply chains. Subtractive manufacturing generates substantial waste, necessitating recycling or disposal processes that contribute to environmental pollution and resource depletion.

Applications and Industry Use Cases

3D printing excels in producing complex geometries and customized prototypes, making it ideal for aerospace, healthcare, and automotive industries requiring rapid iteration and low-volume production. Subtractive manufacturing is preferred for high-precision metal parts in sectors like aerospace and automotive, where durability and tight tolerances are critical. Both technologies complement each other, with 3D printing driving innovation and customization, while subtractive methods ensure strength and finish quality in mass production.

Choosing the Right Method for Your Product Development

3D printing excels in rapid prototyping and complex geometries, enabling cost-effective customization and iterative design changes without tooling expenses. Subtractive manufacturing offers superior surface finish, material strength, and precision for large-scale production with established materials like metals and plastics. Evaluate product complexity, production volume, material requirements, and budget constraints to choose the optimal manufacturing method for efficient product development.

3D printing vs Subtractive manufacturing Infographic

productdif.com

productdif.com