Push fit and interference fit are two common methods used to join components in mechanical assemblies. Push fit relies on precise dimensions allowing parts to slide together with minimal force and form a secure joint through friction, ideal for applications requiring easy assembly and disassembly. Interference fit, also known as press fit, involves slightly oversized parts that require force or heat to assemble, creating a stronger, permanent bond suitable for high-stress environments.

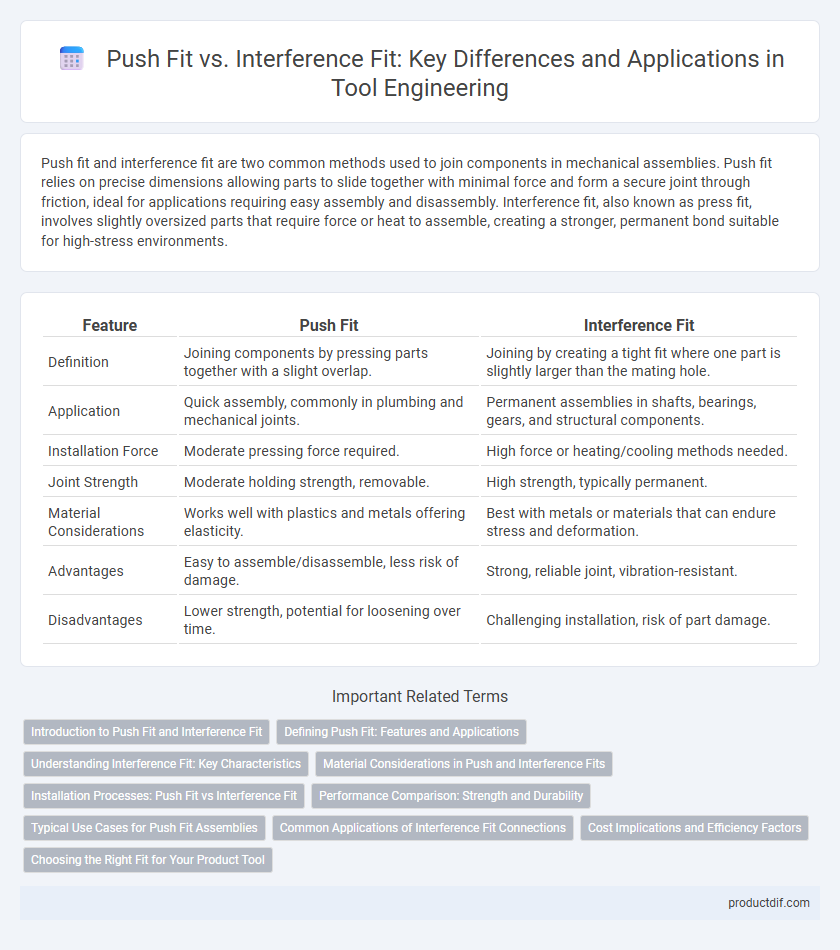

Table of Comparison

| Feature | Push Fit | Interference Fit |

|---|---|---|

| Definition | Joining components by pressing parts together with a slight overlap. | Joining by creating a tight fit where one part is slightly larger than the mating hole. |

| Application | Quick assembly, commonly in plumbing and mechanical joints. | Permanent assemblies in shafts, bearings, gears, and structural components. |

| Installation Force | Moderate pressing force required. | High force or heating/cooling methods needed. |

| Joint Strength | Moderate holding strength, removable. | High strength, typically permanent. |

| Material Considerations | Works well with plastics and metals offering elasticity. | Best with metals or materials that can endure stress and deformation. |

| Advantages | Easy to assemble/disassemble, less risk of damage. | Strong, reliable joint, vibration-resistant. |

| Disadvantages | Lower strength, potential for loosening over time. | Challenging installation, risk of part damage. |

Introduction to Push Fit and Interference Fit

Push fit and interference fit are two common assembly methods used in mechanical engineering to join components without fasteners. Push fit relies on slightly smaller component diameters to allow easy insertion and secure holding through friction, ideal for quick assembly and disassembly. Interference fit, also known as a press fit, involves components designed with overlapping dimensions that require force or heating to assemble, creating a strong, permanent bond through material deformation.

Defining Push Fit: Features and Applications

Push fit is a fastening method where components are joined by pushing one part into another with a slight interference, ensuring a tight, secure connection without the need for additional fasteners or adhesives. This technique relies on precise dimensional tolerances and material elasticity to create frictional holding power, commonly used in assembling plastic or metal parts in automotive, plumbing, and electronic devices. Push fit applications include quick assembly processes, enabling efficient production lines and maintenance-free joints in consumer goods and industrial equipment.

Understanding Interference Fit: Key Characteristics

Interference fit, also known as a press or friction fit, involves parts designed with diameters that ensure a tight assembly by creating pressure between mating surfaces, resulting in a secure, non-slip connection. This fit type is crucial in applications requiring high torque transmission and load-bearing capabilities, as it enhances the mechanical stability without additional fasteners. Precise dimensional control and material selection are vital to achieve the desired interference fit, preventing loosening under operational stresses and ensuring long-term durability.

Material Considerations in Push and Interference Fits

Material considerations in push fit and interference fit tools mainly involve the compatibility of hardness and elasticity between components to ensure secure assembly and function. Push fits require materials with moderate dimensional tolerances and surface finishes that balance ease of insertion with sufficient holding force, often using softer materials or coatings to prevent damage. Interference fits demand materials with higher strength and dimensional stability to withstand the compressive stresses, making metals like steel or hardened alloys preferable for maintaining permanent, robust connections.

Installation Processes: Push Fit vs Interference Fit

Push fit installation involves assembling components with minimal force, relying on slight dimensional differences that allow parts to slide together easily, often requiring only hand pressure or light tapping. Interference fit installation demands precise alignment and significant force or specialized tools like hydraulic presses to deform one or both parts for a tight, permanent connection. The choice between push fit and interference fit impacts the complexity, time, and equipment needed for assembly, influencing overall manufacturing efficiency.

Performance Comparison: Strength and Durability

Push fit connections offer moderate holding strength with easy assembly and disassembly, ideal for applications requiring quick installation and maintenance. Interference fit joints provide superior strength and durability by creating a tight, friction-based bond that withstands high loads and vibrational stresses. The enhanced load-bearing capacity of interference fits makes them preferable for critical mechanical components demanding long-term reliability.

Typical Use Cases for Push Fit Assemblies

Push fit assemblies are commonly used in plumbing and electrical applications where quick, tool-free connections are essential for efficiency and reliability. These fittings provide secure joints in systems requiring frequent assembly and disassembly, such as irrigation systems and pneumatic tubing. The ease of installation and maintenance makes push fit solutions ideal for both residential and commercial environments.

Common Applications of Interference Fit Connections

Interference fit connections are commonly used in mechanical engineering to assemble components requiring a secure and permanent joint, such as gears, bearings, and pulleys on shafts. This method ensures high reliability in high-load and high-speed applications by providing strong frictional forces that resist relative motion between parts. Typical industries employing interference fit connectors include automotive manufacturing, aerospace, and heavy machinery production.

Cost Implications and Efficiency Factors

Push fit connectors offer lower installation costs due to their simple assembly process, reducing labor time and the need for specialized tools. Interference fit joints provide higher mechanical strength but often require precision machining and press equipment, increasing initial manufacturing expenses. Efficiency varies as push fits are ideal for quick, non-permanent assemblies, whereas interference fits ensure durable, long-term performance at a higher cost.

Choosing the Right Fit for Your Product Tool

Selecting the right fit for your product tool depends on the application's load requirements and precision tolerance. Push fit offers easy assembly and disassembly with moderate holding power, ideal for less critical tolerances, while interference fit provides superior strength and resistance through material deformation, suitable for high-stress environments. Consider factors like material properties, operational forces, and maintenance needs to optimize performance and durability.

Push Fit vs Interference Fit Infographic

productdif.com

productdif.com