Crimping provides a faster, more reliable mechanical connection by securely compressing connectors onto wires without the need for heat, reducing the risk of damage and improving electrical conductivity. Soldering, while requiring more skill and time, creates a strong electrical bond by melting metal alloys, which can offer superior durability in high-vibration or harsh environments. Choosing between crimping and soldering depends on the specific application, wire type, and required connection strength for optimal performance.

Table of Comparison

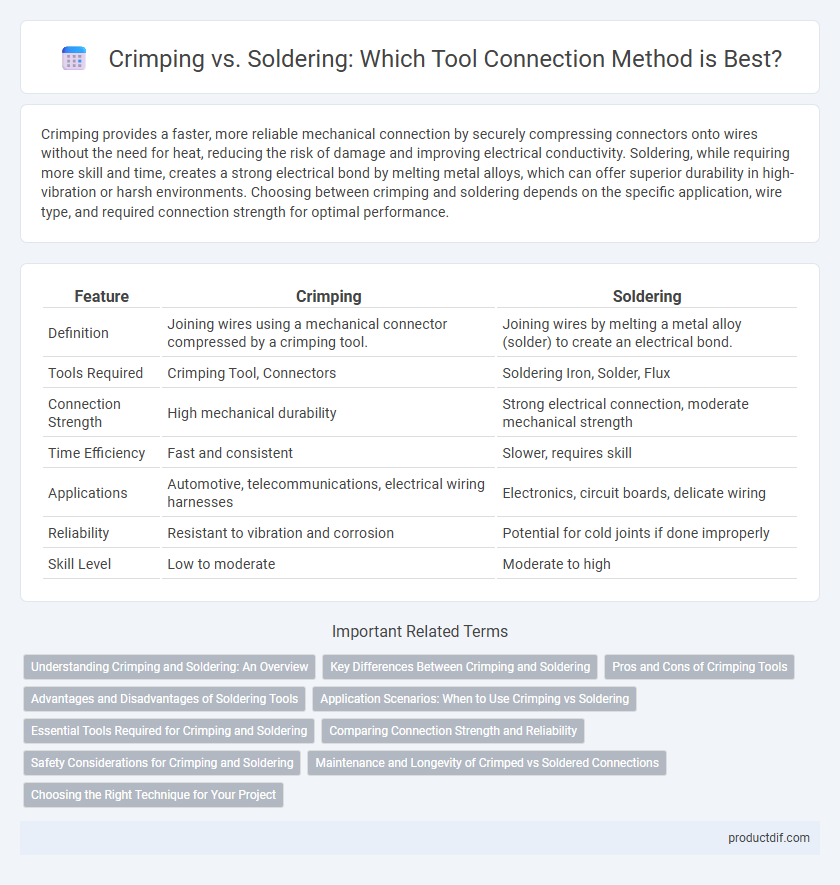

| Feature | Crimping | Soldering |

|---|---|---|

| Definition | Joining wires using a mechanical connector compressed by a crimping tool. | Joining wires by melting a metal alloy (solder) to create an electrical bond. |

| Tools Required | Crimping Tool, Connectors | Soldering Iron, Solder, Flux |

| Connection Strength | High mechanical durability | Strong electrical connection, moderate mechanical strength |

| Time Efficiency | Fast and consistent | Slower, requires skill |

| Applications | Automotive, telecommunications, electrical wiring harnesses | Electronics, circuit boards, delicate wiring |

| Reliability | Resistant to vibration and corrosion | Potential for cold joints if done improperly |

| Skill Level | Low to moderate | Moderate to high |

Understanding Crimping and Soldering: An Overview

Crimping and soldering are essential techniques for creating secure electrical connections, with crimping involving the mechanical deformation of a connector onto a wire, ensuring a reliable, gas-tight joint without heat. Soldering uses molten metal alloy to bond components, offering excellent conductivity and mechanical strength but requiring precise temperature control to avoid damage. Both methods serve critical roles in electronics and wiring applications, with crimping favored for speed and consistency, while soldering provides superior electrical continuity and durability in complex assemblies.

Key Differences Between Crimping and Soldering

Crimping involves mechanically deforming a connector to create a secure electrical connection without heat, making it faster and more reliable for high-vibration environments. Soldering uses molten metal to join components, providing a strong, conductive bond but requiring skilled technique and time for cooling. Key differences include crimping's consistency and repeatability versus soldering's superior conductivity and flexibility in repair applications.

Pros and Cons of Crimping Tools

Crimping tools offer rapid and consistent wire connections, reducing installation time and minimizing the need for heat, which enhances safety and reliability in electrical work. They provide strong mechanical bonds without the risk of cold solder joints or damage caused by excessive heat, making them ideal for repetitive tasks and harsh environments. However, crimping requires precise tool calibration and compatible connectors to avoid weak connections, and the initial investment in quality crimping tools can be higher compared to soldering equipment.

Advantages and Disadvantages of Soldering Tools

Soldering tools provide precise, reliable connections with excellent electrical conductivity, making them ideal for delicate electronic components and complex circuits. However, soldering requires skill and time, and excessive heat can damage sensitive parts or insulation. Despite these drawbacks, soldering remains a preferred technique for permanent, low-resistance joints in electronics assembly.

Application Scenarios: When to Use Crimping vs Soldering

Crimping is ideal for high-volume production and automotive wiring where speed, reliability, and vibration resistance are critical. Soldering is preferred in electronics and delicate circuits requiring strong electrical connections and minimal resistance. Choosing between crimping and soldering depends on the application's mechanical demands, environmental factors, and required conductivity.

Essential Tools Required for Crimping and Soldering

Crimping requires essential tools such as a quality crimping tool with interchangeable dies, wire strippers, and connectors suited for the gauge of wire being used. Soldering demands a soldering iron with adjustable temperature control, rosin-core solder, flux, and heat-resistant gloves to ensure secure and precise joints. Both methods benefit from additional tools like multimeters for testing and helping maintain reliable electrical connections.

Comparing Connection Strength and Reliability

Crimping provides a mechanically robust connection by compressing metal connectors onto wires, ensuring consistent electrical contact and resistance to vibration or corrosion. Soldering creates a chemically bonded joint that offers superior conductivity and long-term stability but can be prone to mechanical failure if subjected to stress or temperature fluctuations. Evaluating connection strength and reliability depends on application requirements, with crimping favored for high-vibration environments and soldering preferred for precision electronic assemblies.

Safety Considerations for Crimping and Soldering

Crimping ensures a mechanically secure and reliable electrical connection without the need for heat, reducing fire hazards and minimizing operator injury risks compared to soldering. Soldering involves high temperatures and molten metal, posing burn and inhalation hazards, which require proper ventilation and protective equipment. Using crimping tools with insulated handles and proper technique further enhances safety and connection integrity in electrical work.

Maintenance and Longevity of Crimped vs Soldered Connections

Crimped connections require minimal maintenance due to their solid mechanical bond and resistance to corrosion, ensuring long-term reliability in harsh environments. Soldered connections, while providing excellent electrical conductivity, often need periodic inspection and re-soldering as they can develop brittle joints over time from thermal cycling. The durability of crimped connections typically surpasses soldered ones in applications with high vibration or mechanical stress, resulting in longer-lasting electrical performance.

Choosing the Right Technique for Your Project

Selecting the appropriate connection method between crimping and soldering depends on project requirements such as durability, electrical conductivity, and environmental conditions. Crimping offers faster installation with consistent mechanical strength ideal for high-vibration environments, while soldering provides superior electrical conductivity and is preferred for delicate electronic circuits requiring precise control. Evaluating factors like tool availability, skill level, and maintenance needs ensures the optimal technique enhances connection reliability and performance.

Crimping vs Soldering Infographic

productdif.com

productdif.com