Handheld tools offer portability and precision, allowing users to perform tasks in various locations with ease and control. Stationary tools provide greater power and stability, ideal for repetitive or heavy-duty work that requires consistent performance. Choosing between handheld and stationary tools depends on the specific project requirements, workspace availability, and desired accuracy.

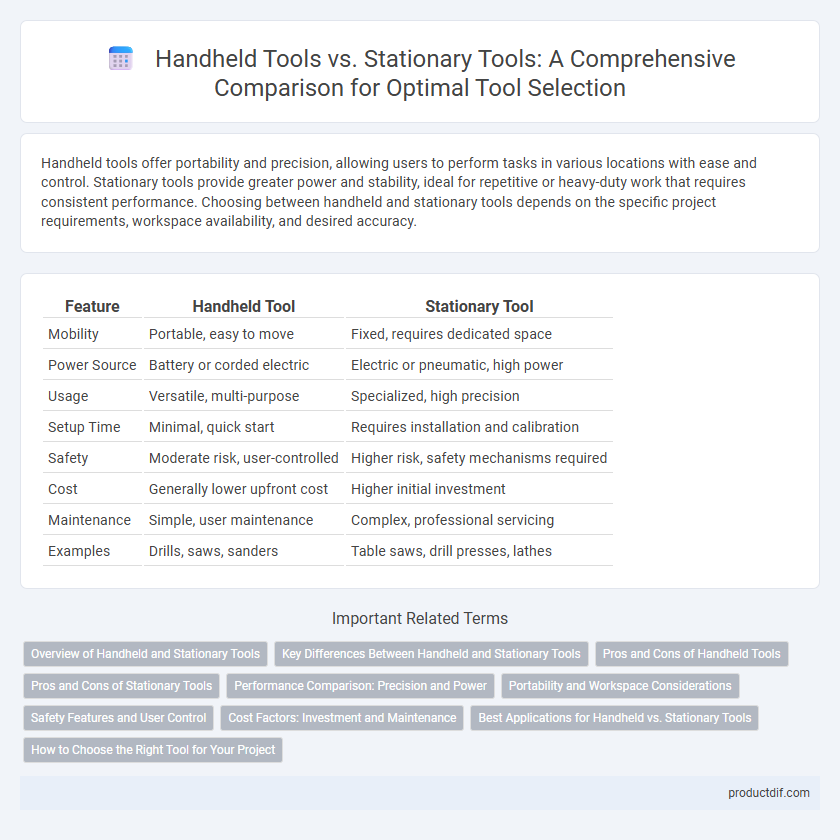

Table of Comparison

| Feature | Handheld Tool | Stationary Tool |

|---|---|---|

| Mobility | Portable, easy to move | Fixed, requires dedicated space |

| Power Source | Battery or corded electric | Electric or pneumatic, high power |

| Usage | Versatile, multi-purpose | Specialized, high precision |

| Setup Time | Minimal, quick start | Requires installation and calibration |

| Safety | Moderate risk, user-controlled | Higher risk, safety mechanisms required |

| Cost | Generally lower upfront cost | Higher initial investment |

| Maintenance | Simple, user maintenance | Complex, professional servicing |

| Examples | Drills, saws, sanders | Table saws, drill presses, lathes |

Overview of Handheld and Stationary Tools

Handheld tools offer portability and versatility, making them ideal for tasks that require mobility and precision in various environments. Stationary tools, mounted on a fixed platform, provide stability and power for repetitive or heavy-duty operations, ensuring consistent accuracy and safety. Selecting between handheld and stationary tools depends on the specific application, workspace constraints, and the nature of the task to optimize efficiency and results.

Key Differences Between Handheld and Stationary Tools

Handheld tools offer portability and flexibility, enabling users to perform tasks in various locations and confined spaces, whereas stationary tools provide higher precision and power, ideal for repetitive, heavy-duty operations. Handheld tools are typically powered by batteries or electricity, emphasizing ease of use and maneuverability, while stationary tools are fixed installations that support larger workpieces and offer enhanced stability. The choice between handheld and stationary tools depends on project scale, accuracy requirements, and workspace constraints.

Pros and Cons of Handheld Tools

Handheld tools offer unmatched portability and versatility, allowing precise work in tight or remote spaces, making them ideal for on-site tasks and quick repairs. Their lightweight design reduces operator fatigue but often comes with lower power and stability compared to stationary tools, which can limit efficiency on heavy-duty projects. Safety risks increase due to manual handling, requiring greater skill and attention, while handheld tools generally cost less and occupy minimal storage space.

Pros and Cons of Stationary Tools

Stationary tools offer superior stability and precision, making them ideal for repetitive and high-accuracy tasks in manufacturing and woodworking. They often accommodate larger workpieces and provide greater power compared to handheld tools, enhancing efficiency for heavy-duty operations. However, stationary tools lack portability and flexibility, limiting their use to fixed locations and requiring dedicated workspace.

Performance Comparison: Precision and Power

Handheld tools offer versatile precision for detailed tasks, benefiting from ergonomic control and maneuverability, while stationary tools provide superior power and stability, ideal for repetitive or heavy-duty operations. Precision in handheld tools is often enhanced by operator skill, whereas stationary tools maintain consistent accuracy through fixed setups and automated guides. Power output in stationary tools generally surpasses handheld alternatives, enabling efficient processing of tougher materials and prolonged usage without operator fatigue.

Portability and Workspace Considerations

Handheld tools offer unmatched portability, allowing users to easily transport and operate them in various locations, making them ideal for on-site tasks or limited workspaces. In contrast, stationary tools require dedicated workspace, often providing greater stability and precision but limiting mobility and flexibility. Choosing between handheld and stationary tools depends on the balance between the need for portability and the workspace environment available.

Safety Features and User Control

Handheld tools prioritize ergonomic designs with enhanced grip materials and integrated safety switches to minimize user fatigue and accidental activation, offering greater mobility and direct control. Stationary tools incorporate robust safety enclosures, emergency stop buttons, and blade guards to ensure operator protection during prolonged, high-powered operations in fixed settings. Both tool types emphasize user safety, but handheld tools balance portability with control, while stationary tools focus on safeguarding users in controlled environments.

Cost Factors: Investment and Maintenance

Handheld tools generally require lower initial investment compared to stationary tools, making them cost-effective for small-scale or mobile tasks. Maintenance costs for handheld tools are often reduced due to simpler mechanisms and easier access for repairs, whereas stationary tools demand higher upkeep expenses owing to complex components and fixed installation. The total cost of ownership analysis should consider purchase price, maintenance frequency, and operational efficiency to determine the best tool investment.

Best Applications for Handheld vs. Stationary Tools

Handheld tools excel in tasks requiring portability and precision, such as drilling in tight spaces, cutting, or light assembly work. Stationary tools are best suited for repetitive, high-precision tasks like woodworking, metal shaping, and milling where stability and power are crucial. Selecting the right tool depends on the job's mobility demands and accuracy requirements to ensure efficiency and safety.

How to Choose the Right Tool for Your Project

Choosing the right tool for your project depends on the specific task requirements and workspace constraints. Handheld tools offer portability and flexibility for smaller, varied tasks, while stationary tools provide stability and precision for repetitive or heavy-duty operations. Evaluate project size, material type, and desired accuracy to decide between the convenience of handheld tools and the power of stationary equipment.

Handheld tool vs Stationary tool Infographic

productdif.com

productdif.com