An adjustable tool offers versatility by allowing modifications to fit different sizes or shapes, making it ideal for varied tasks. In contrast, a fixed tool provides stability and precision for specific applications, often resulting in enhanced durability and performance. Choosing between adjustable and fixed tools depends on the need for flexibility versus specialized function.

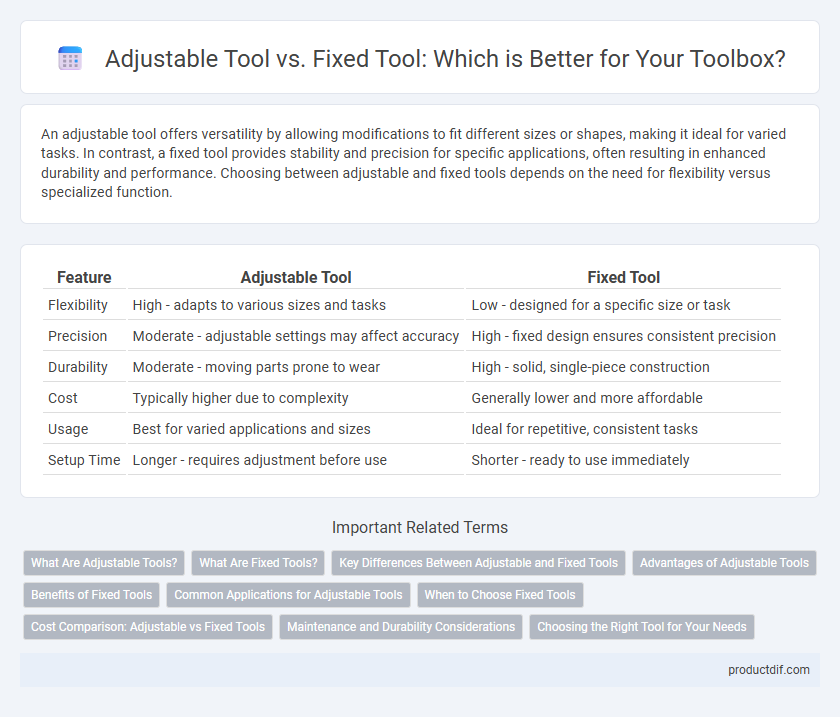

Table of Comparison

| Feature | Adjustable Tool | Fixed Tool |

|---|---|---|

| Flexibility | High - adapts to various sizes and tasks | Low - designed for a specific size or task |

| Precision | Moderate - adjustable settings may affect accuracy | High - fixed design ensures consistent precision |

| Durability | Moderate - moving parts prone to wear | High - solid, single-piece construction |

| Cost | Typically higher due to complexity | Generally lower and more affordable |

| Usage | Best for varied applications and sizes | Ideal for repetitive, consistent tasks |

| Setup Time | Longer - requires adjustment before use | Shorter - ready to use immediately |

What Are Adjustable Tools?

Adjustable tools feature components that can be modified to fit various sizes or applications, offering versatility for multiple tasks. Common examples include adjustable wrenches, clamps, and pliers, which can adapt to different fasteners or materials. These tools enhance efficiency and reduce the need for multiple single-size tools in a toolkit.

What Are Fixed Tools?

Fixed tools are specialized instruments designed with a set shape and size, offering consistent performance for repetitive tasks in manufacturing and machining. Unlike adjustable tools, fixed tools provide precise accuracy and stability, minimizing variability during operations such as cutting, drilling, or shaping materials. Their rigid construction ensures durability and reliability in high-volume production environments where uniformity is critical.

Key Differences Between Adjustable and Fixed Tools

Adjustable tools offer versatility by allowing users to modify size or shape to fit various tasks, whereas fixed tools are designed for a specific function with a set dimension. The primary difference lies in adjustability, with adjustable tools providing flexibility and fixed tools delivering consistent precision for repetitive work. Material durability and maintenance requirements also vary, as fixed tools often require less upkeep compared to the moving parts in adjustable tools.

Advantages of Adjustable Tools

Adjustable tools offer enhanced versatility by allowing users to modify settings to fit various tasks, reducing the need for multiple specialized tools. These tools provide cost efficiency and space savings, as one adjustable tool can substitute several fixed equivalents. Increased precision and customization improve work quality, making adjustable tools highly valuable for complex or variable projects.

Benefits of Fixed Tools

Fixed tools provide superior durability and stability, making them ideal for high-precision tasks and repetitive operations. Their rigid structure ensures consistent performance, reducing errors and maintenance needs. These tools also deliver faster setup times, enhancing overall productivity in manufacturing and construction environments.

Common Applications for Adjustable Tools

Adjustable tools are widely used in plumbing, mechanical repair, and woodworking due to their versatility in handling various fastener sizes and shapes. Common adjustable tools include wrenches, clamps, and pliers, which provide flexibility for tightening, loosening, or gripping objects without the need for multiple fixed-size tools. Their adaptability improves efficiency, reduces tool inventory costs, and simplifies troubleshooting in both professional and DIY settings.

When to Choose Fixed Tools

Fixed tools are ideal for high-volume production runs where consistency and durability are paramount, minimizing setup times and ensuring uniform output. Their robust design withstands repetitive use without the need for frequent adjustments, making them cost-effective for standardized tasks. Industries like automotive manufacturing and metal stamping often rely on fixed tools to maximize efficiency and reduce errors.

Cost Comparison: Adjustable vs Fixed Tools

Adjustable tools typically incur higher initial costs than fixed tools due to their complex design and versatility, enabling multiple functions with a single device. Fixed tools generally offer lower upfront expenses and simpler maintenance, making them cost-effective for repetitive tasks with consistent specifications. Over time, the adaptability of adjustable tools can reduce the need for multiple fixed tools, potentially lowering overall operational costs despite the higher initial investment.

Maintenance and Durability Considerations

Adjustable tools require regular calibration and lubrication to maintain optimal performance, while fixed tools generally demand less frequent maintenance due to their simpler design. The durability of fixed tools often surpasses adjustable counterparts because fewer moving parts reduce wear and potential failure points. Choosing between adjustable and fixed tools depends on balancing flexibility needs against long-term maintenance efforts and lifespan expectations.

Choosing the Right Tool for Your Needs

Choosing the right tool depends on the specific task requirements and precision needed, with adjustable tools offering flexibility for varying sizes and applications. Fixed tools provide greater stability and accuracy for repetitive tasks where dimensions remain constant. Evaluating factors like project scope, frequency of use, and required durability ensures optimal performance and cost-effectiveness.

Adjustable Tool vs Fixed Tool Infographic

productdif.com

productdif.com