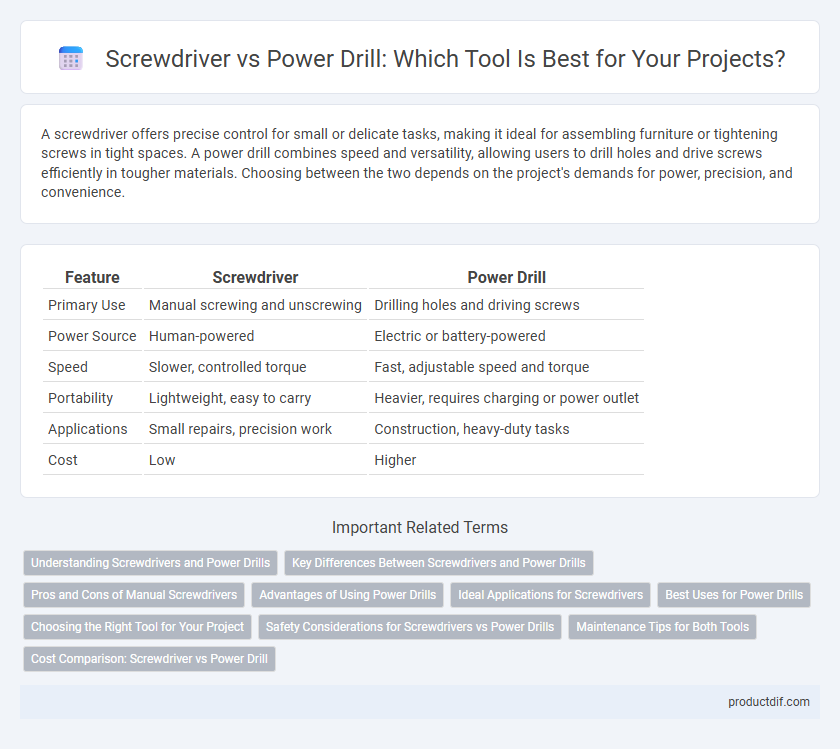

A screwdriver offers precise control for small or delicate tasks, making it ideal for assembling furniture or tightening screws in tight spaces. A power drill combines speed and versatility, allowing users to drill holes and drive screws efficiently in tougher materials. Choosing between the two depends on the project's demands for power, precision, and convenience.

Table of Comparison

| Feature | Screwdriver | Power Drill |

|---|---|---|

| Primary Use | Manual screwing and unscrewing | Drilling holes and driving screws |

| Power Source | Human-powered | Electric or battery-powered |

| Speed | Slower, controlled torque | Fast, adjustable speed and torque |

| Portability | Lightweight, easy to carry | Heavier, requires charging or power outlet |

| Applications | Small repairs, precision work | Construction, heavy-duty tasks |

| Cost | Low | Higher |

Understanding Screwdrivers and Power Drills

Screwdrivers are hand tools designed for driving screws, offering precision and control in delicate tasks, while power drills use motorized torque to quickly drive screws and drill holes in various materials. Power drills often include variable speed settings, adjustable clutch controls, and interchangeable bits, making them versatile for heavy-duty and repetitive jobs. Understanding the specific application, whether precise manual screwing or expedited drilling, helps choose between a screwdriver and a power drill for efficient project completion.

Key Differences Between Screwdrivers and Power Drills

Screwdrivers are primarily designed for driving and removing screws with manual or electric torque, offering precise control for smaller tasks. Power drills provide higher torque and speed, enabling drilling through tougher materials and faster screw driving, often featuring interchangeable drill bits and adjustable clutch settings. The key difference lies in their functionality: screwdrivers specialize in fastening, while power drills combine drilling and screwdriving capabilities for versatile applications.

Pros and Cons of Manual Screwdrivers

Manual screwdrivers offer precise control and are ideal for small or delicate tasks, minimizing the risk of over-tightening screws. They are lightweight, inexpensive, and require no power source, making them portable and reliable for quick fixes. However, manual use can be time-consuming and physically demanding for larger projects compared to powered alternatives like power drills.

Advantages of Using Power Drills

Power drills offer superior torque and speed compared to screwdrivers, enabling faster and more efficient fastening and drilling tasks. Their versatility includes multiple settings for different materials, making them ideal for both heavy-duty and delicate projects. The ergonomic design and battery-powered convenience reduce user fatigue and improve portability on various job sites.

Ideal Applications for Screwdrivers

Screwdrivers are ideal for tasks requiring precision and control, such as assembling furniture, tightening small screws in electronics, and delicate woodworking projects. Their lightweight design allows for extended use without causing user fatigue, making them perfect for repetitive or low-torque fastening jobs. Manual screwdrivers excel in tight spaces where power drills may be cumbersome or risk damaging materials.

Best Uses for Power Drills

Power drills excel in tasks requiring both drilling and driving screws, making them ideal for construction, woodworking, and metalworking projects. Their adjustable torque and speed settings allow for efficient handling of various materials such as wood, metal, and plastic with precision. Power drills also support multiple attachments, expanding their functionality beyond simple screwdriving to hole drilling, mixing, and sanding.

Choosing the Right Tool for Your Project

Selecting the right tool for your project depends on the specific task requirements and material type. Screwdrivers provide precise control for smaller, detailed work or tight spaces, while power drills offer efficient speed and torque for drilling holes and driving multiple screws quickly. Evaluating the scale and complexity of your project ensures you choose a tool that maximizes efficiency and accuracy.

Safety Considerations for Screwdrivers vs Power Drills

Screwdrivers offer greater control and lower risk of injury when performing light tasks due to their manual operation and reduced torque. Power drills require careful handling to avoid accidents such as stripped screws, hand injuries, or damage to materials from high speed and torque. Wearing protective gear like gloves and safety glasses is essential when using power drills to enhance user safety and prevent debris-related injuries.

Maintenance Tips for Both Tools

Regularly clean screwdriver tips and power drill chucks to prevent rust and ensure precise operation. Lubricate moving parts of power drills and tighten screwdriver handles to maintain functionality. Store both tools in dry environments to extend lifespan and avoid damage.

Cost Comparison: Screwdriver vs Power Drill

A manual screwdriver typically costs between $5 and $20, offering a budget-friendly option for simple tasks and occasional use. Power drills range from $50 to over $200, depending on features such as battery life, torque, and brand quality, representing a higher initial investment but greater versatility. Long-term value favors power drills due to their efficiency and ability to handle a wide range of projects, despite the upfront cost difference.

Screwdriver vs Power Drill Infographic

productdif.com

productdif.com