Cold forging produces tools with superior surface finish and enhanced dimensional accuracy due to deformation at room temperature, which maintains the metal's grain structure and hardness. Hot forging, performed above the metal's recrystallization temperature, allows for easier shaping of complex geometries and reduces material stresses but may result in lower surface quality and dimensional precision. Selecting between cold and hot forging depends on the desired tool properties, production volume, and cost efficiency.

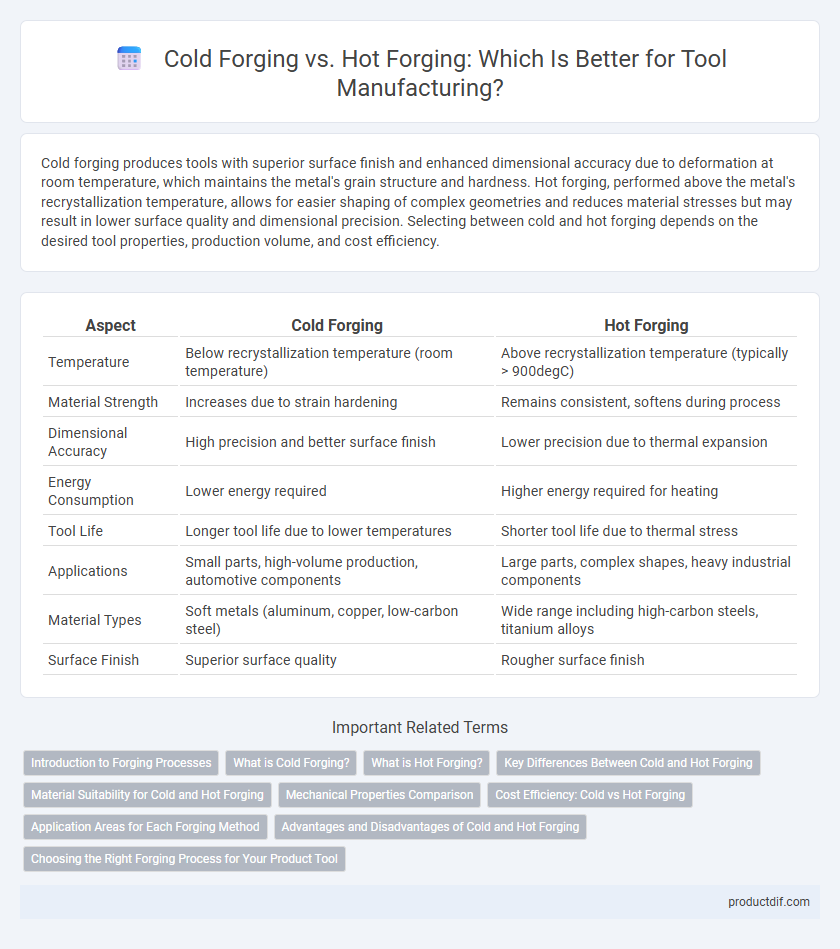

Table of Comparison

| Aspect | Cold Forging | Hot Forging |

|---|---|---|

| Temperature | Below recrystallization temperature (room temperature) | Above recrystallization temperature (typically > 900degC) |

| Material Strength | Increases due to strain hardening | Remains consistent, softens during process |

| Dimensional Accuracy | High precision and better surface finish | Lower precision due to thermal expansion |

| Energy Consumption | Lower energy required | Higher energy required for heating |

| Tool Life | Longer tool life due to lower temperatures | Shorter tool life due to thermal stress |

| Applications | Small parts, high-volume production, automotive components | Large parts, complex shapes, heavy industrial components |

| Material Types | Soft metals (aluminum, copper, low-carbon steel) | Wide range including high-carbon steels, titanium alloys |

| Surface Finish | Superior surface quality | Rougher surface finish |

Introduction to Forging Processes

Cold forging and hot forging are fundamental metalworking processes used to shape metals by applying compressive forces. Cold forging occurs at or near room temperature, resulting in superior surface finish, increased strength through strain hardening, and enhanced dimensional accuracy. Hot forging involves heating metals above their recrystallization temperature, allowing easier deformation, improved ductility, and the ability to form complex shapes with reduced risk of cracks.

What is Cold Forging?

Cold forging is a metal forming process performed at or near room temperature, where metal is shaped by applying high pressure without heating the material. This method enhances the metal's strength, surface finish, and dimensional accuracy while reducing waste and production time compared to hot forging. Common applications include manufacturing fasteners, bolts, and precision components for automotive and aerospace industries.

What is Hot Forging?

Hot forging is a metal shaping process performed above the metal's recrystallization temperature, typically exceeding 1,000degF (540degC), which enhances material ductility and reduces deformation resistance. This technique allows for the creation of complex shapes and improved mechanical properties by refining the grain structure during deformation. Common applications include automotive components, aerospace parts, and heavy machinery where strength and durability are critical.

Key Differences Between Cold and Hot Forging

Cold forging involves shaping metal at or near room temperature, resulting in increased strength and improved surface finish due to strain hardening, while hot forging is performed above the metal's recrystallization temperature, allowing for easier deformation and reduced residual stresses. Key differences include cold forging's higher dimensional accuracy and superior mechanical properties versus hot forging's greater ability to produce complex shapes and reduce machining requirements. Tool wear is generally lower in hot forging due to softened material but cold forging tools must withstand higher stress from harder workpieces.

Material Suitability for Cold and Hot Forging

Cold forging is ideal for materials with high ductility such as aluminum, copper, and low-carbon steel, as these metals maintain their strength and surface finish when shaped at room temperature. Hot forging suits materials like high-carbon steels, stainless steels, and titanium alloys, which require elevated temperatures to improve formability and reduce cracking during deformation. Understanding material properties such as recrystallization temperature and strain hardening behavior is crucial for selecting the appropriate forging process.

Mechanical Properties Comparison

Cold forging produces parts with superior tensile strength, hardness, and fatigue resistance due to strain hardening at lower temperatures. Hot forging allows for greater ductility and toughness by refining grain structure through recrystallization during deformation at elevated temperatures. Mechanical properties optimization depends on specific application requirements, balancing strength and formability in cold forging versus improved ductility and reduced residual stresses in hot forging.

Cost Efficiency: Cold vs Hot Forging

Cold forging generally offers higher cost efficiency due to reduced energy consumption and minimal material waste, making it ideal for high-volume production runs. Hot forging, while requiring more energy and additional heating equipment, allows for easier shaping of complex geometries and can reduce machining costs post-forging. Selecting between cold and hot forging depends on balancing upfront energy costs against material properties and production volume demands.

Application Areas for Each Forging Method

Cold forging is commonly used for manufacturing high-precision components such as bolts, screws, and connectors in the automotive and aerospace industries due to its ability to produce parts with superior surface finish and dimensional accuracy. Hot forging is preferred in heavy industries like construction, shipbuilding, and oil and gas for producing large, complex parts like crankshafts, gears, and turbine blades that require enhanced material strength and durability. Each method's application area hinges on factors like material type, desired mechanical properties, and production volume, with cold forging excelling in small, detailed parts and hot forging suited for robust, large-scale components.

Advantages and Disadvantages of Cold and Hot Forging

Cold forging offers higher dimensional accuracy, improved surface finish, and increased strength due to strain hardening, making it ideal for precision components with minimal material waste. Hot forging allows for the formation of complex shapes with lower forging forces and reduced risk of workpiece cracking, but it often results in scale formation and less surface finish quality. While cold forging has limitations with material ductility and higher tooling costs, hot forging requires additional energy for heating and can cause grain growth affecting mechanical properties.

Choosing the Right Forging Process for Your Product Tool

Cold forging offers superior dimensional accuracy and surface finish, making it ideal for producing high-precision tools with minimal material waste. Hot forging enhances material ductility, allowing for complex shapes and larger components but may require additional machining due to scale formation. Selecting between cold and hot forging depends on factors such as tool design complexity, production volume, and desired mechanical properties to ensure optimal performance and cost-efficiency.

Cold Forging vs Hot Forging Infographic

productdif.com

productdif.com